Production process for hardware fitting and insulator tandem connection integrated device

A technology of insulator string and production process, which is applied in the electrical field, can solve the problems of weakened operation reliability, inconvenient construction, difficult maintenance, etc., and achieve the effect of product strength balance and strength balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not used to limit the scope of the present invention.

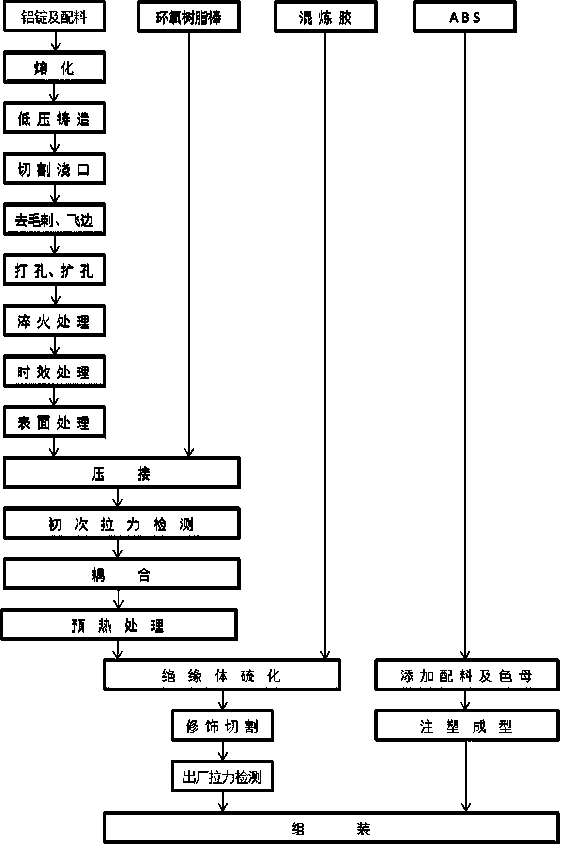

[0026] Such as figure 1 Shown is a production process flow chart of an integrated device for connecting hardware and insulators in series, including the following steps:

[0027] Step 1. Low-pressure casting of tension clamps with crimp holes, including: melting aluminum ingots and ingredients; using 114A process for low-pressure casting; cutting and burning; deburring and flashing; punching and reaming; using T5 Quenching treatment; aging treatment; surface shot blasting treatment;

[0028] Step 2: Low-pressure casting of connecting fittings with crimp holes;

[0029] Step three: make an insulator; the specific implementation method is: apply coupling agent to the surface of the epoxy resin rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com