Solid state fermentation reactor equipped with active support material

A bioreactor and support technology, applied in the field of fermentation, can solve the problems of low capillary conductivity of liquid and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Preferred conditions for porous solid supports were tested using a mixture comprising vermiculite, perlite and cation exchange resin.

[0075] Table 1. Physical properties of the solid support from a mixture of vermiculite (40vol%, 2-4mm), synthetic cation exchange resin (40vol%, 0.7mm) and perlite (20vol%, 1-2mm)

[0076]

[0077] Table 1 shows that the largest pores did not produce large liquid-gas interfaces. Excessive particle size reduction rapidly produces low water conductivity. The size of the pores between the particles is between 1 / 4 and 1 / 2 the size of the particles.

[0078] If according to the Sabatier equation CO 2 +4H 2 ->CH 4 +2H 2 O, a bioreactor producing methane from hydrogen and carbon dioxide at an efficiency (power) of 10 W / l produces water at a rate of 1.35 g / h / l. This means a water downflow of 0.135 cm / h at the bottom of the bioreactor structure close to one meter high.

[0079] The water conductance values in Table 1 indicate that su...

Embodiment 2

[0082] This example shows that liquid products are drained from a solid state fermentation reactor by gravity.

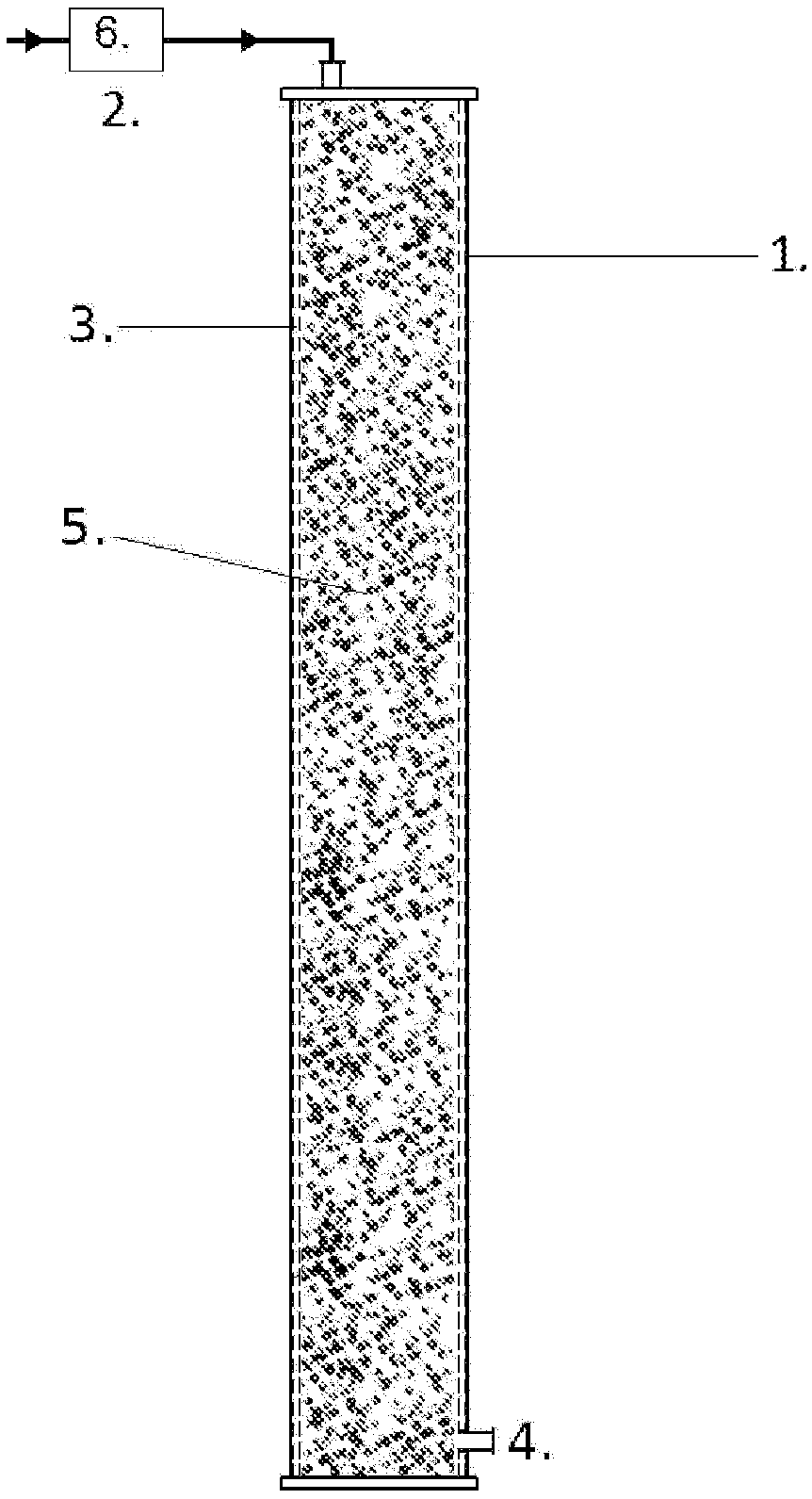

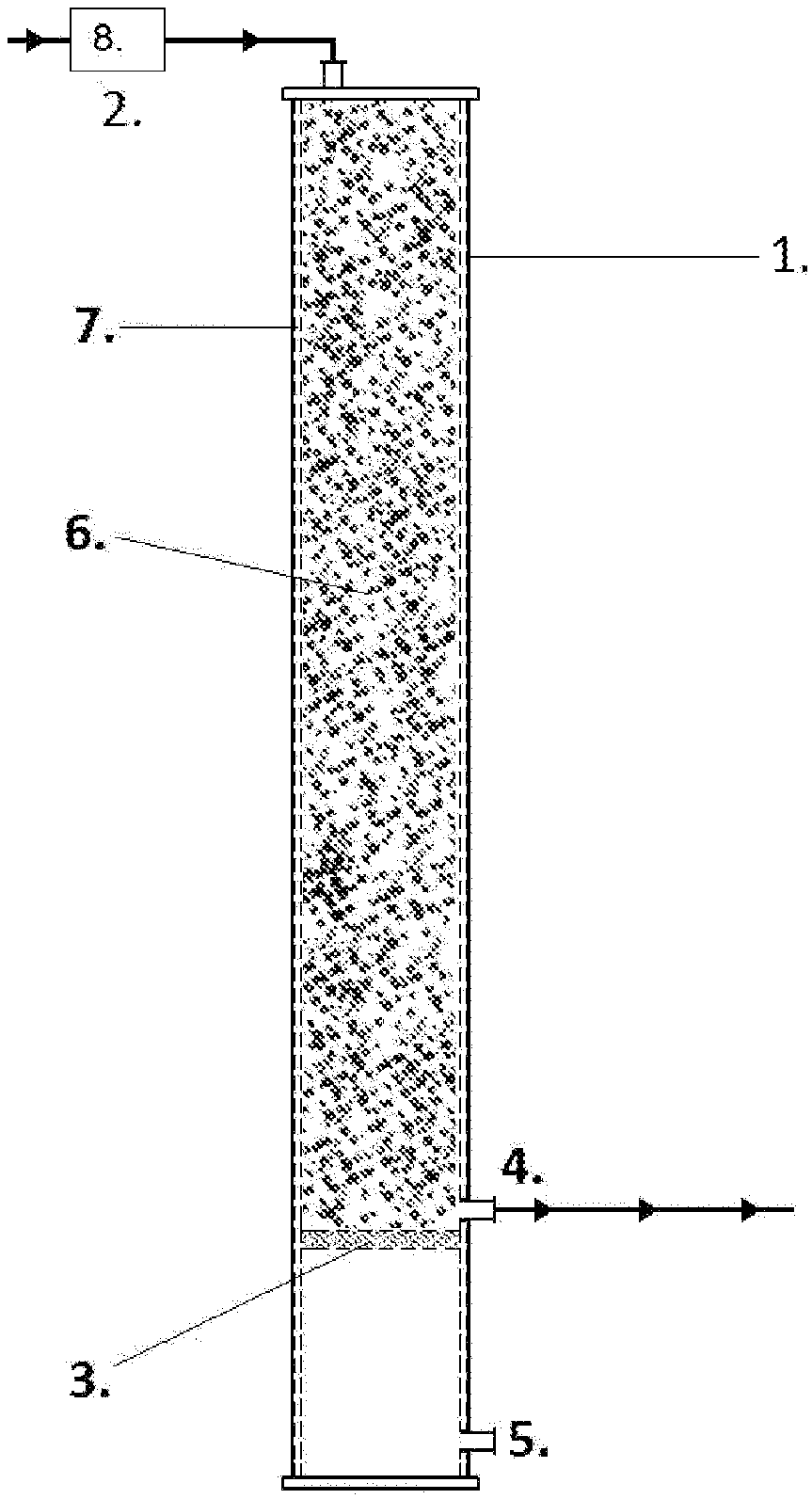

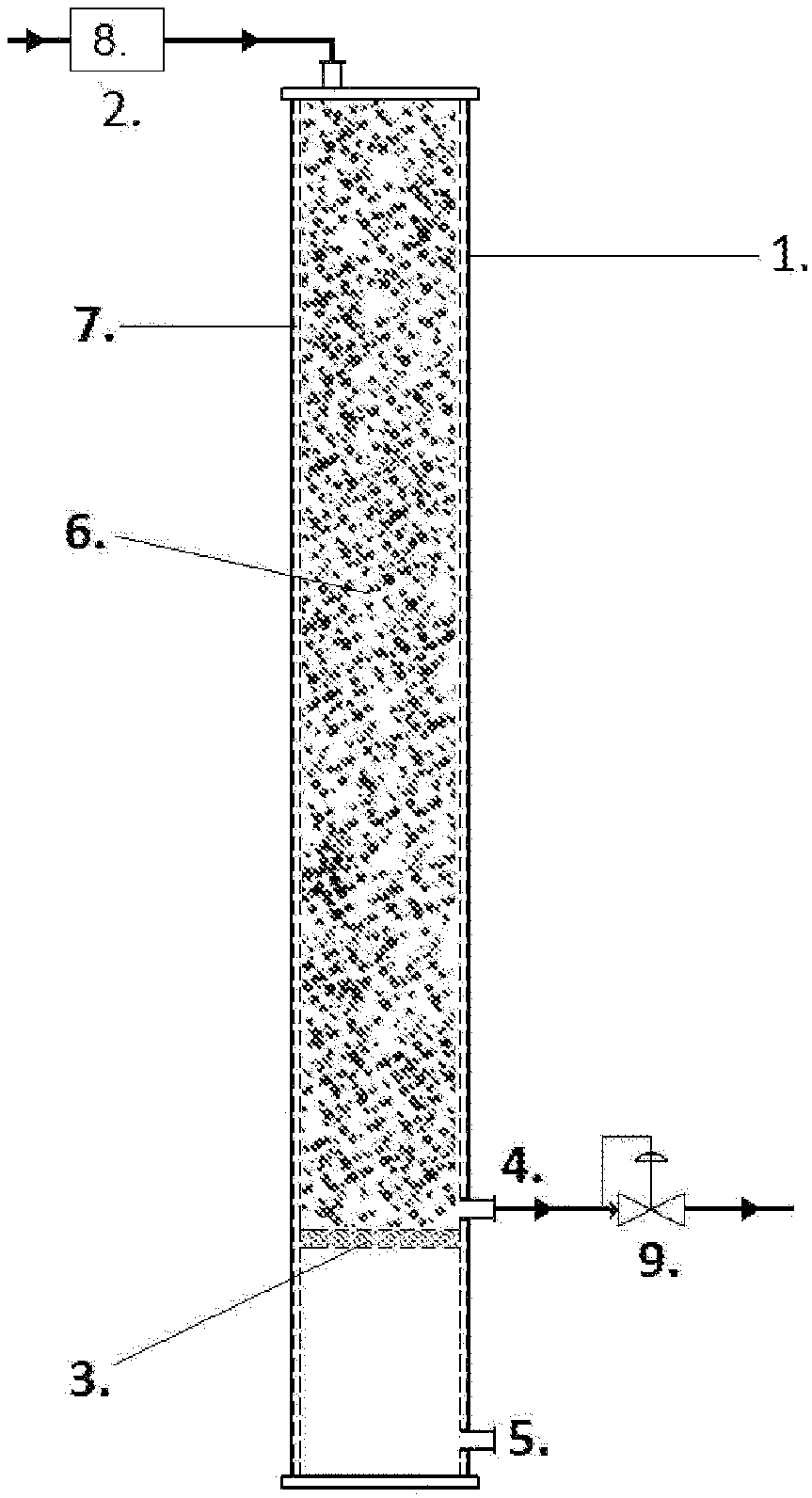

[0083] according to figure 1 A bioreactor was constructed from polypropylene sewage pipes (75 mm inner diameter, 500 mm height, 2 L working volume) as shown in . Fit the nylon inlet tube for gas into the upper part of the pipe. Regulate the gas supply with a mass flow controller. The bioreactor is equipped with outlet pipes installed in the lower part of the pipes for gaseous and liquid end product collection.

[0084] The upper part of the sewage pipe of the bioreactor is filled with a solid support. A solid support was created by mixing 6L 2-4mm vermiculite with 2L 2-5mm perlite and 2L cation exchange resin prior to filling. In addition, sources of N and P supplemented by other materials are added to this mixture to serve as sources of nutrients and trace elements for biological reactions. The bioreactor is inoculated with microbial ammonia oxidizing bacteria...

Embodiment 3

[0087] This example shows that solid product (cellular biomass) is drawn out of a solid state fermentation reactor by gravity. Specifically, in this example, microbial proteins were produced from methane using bioconversion in a solid-state fermentation reactor.

[0088] according to figure 1 A bioreactor was constructed from polypropylene sewage pipes (75 mm inner diameter, 500 mm height, 2 L working volume) as shown in . Fit the nylon inlet tube for gas into the upper part of the pipe. The gas feed mixture of methane and oxygen was regulated with a mass flow controller. The bioreactor is equipped with outlet pipes installed in the lower part of the pipes for collection of gaseous, liquid and solid end products (single-cell proteinaceous biomass).

[0089] The upper part of the sewage pipe of the bioreactor is filled with a solid support. A solid support was created by mixing 6L 2-4mm vermiculite with 2L 2-5mm perlite and 2L cation exchange resin prior to filling. Furthe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com