Water injection device, in particular of an internal combustion engine, and method for operating such a water injection device

A technology for water injection equipment and internal combustion engines, which can be applied to internal combustion piston engines, mechanical equipment, combustion engines, etc., and can solve problems such as low pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

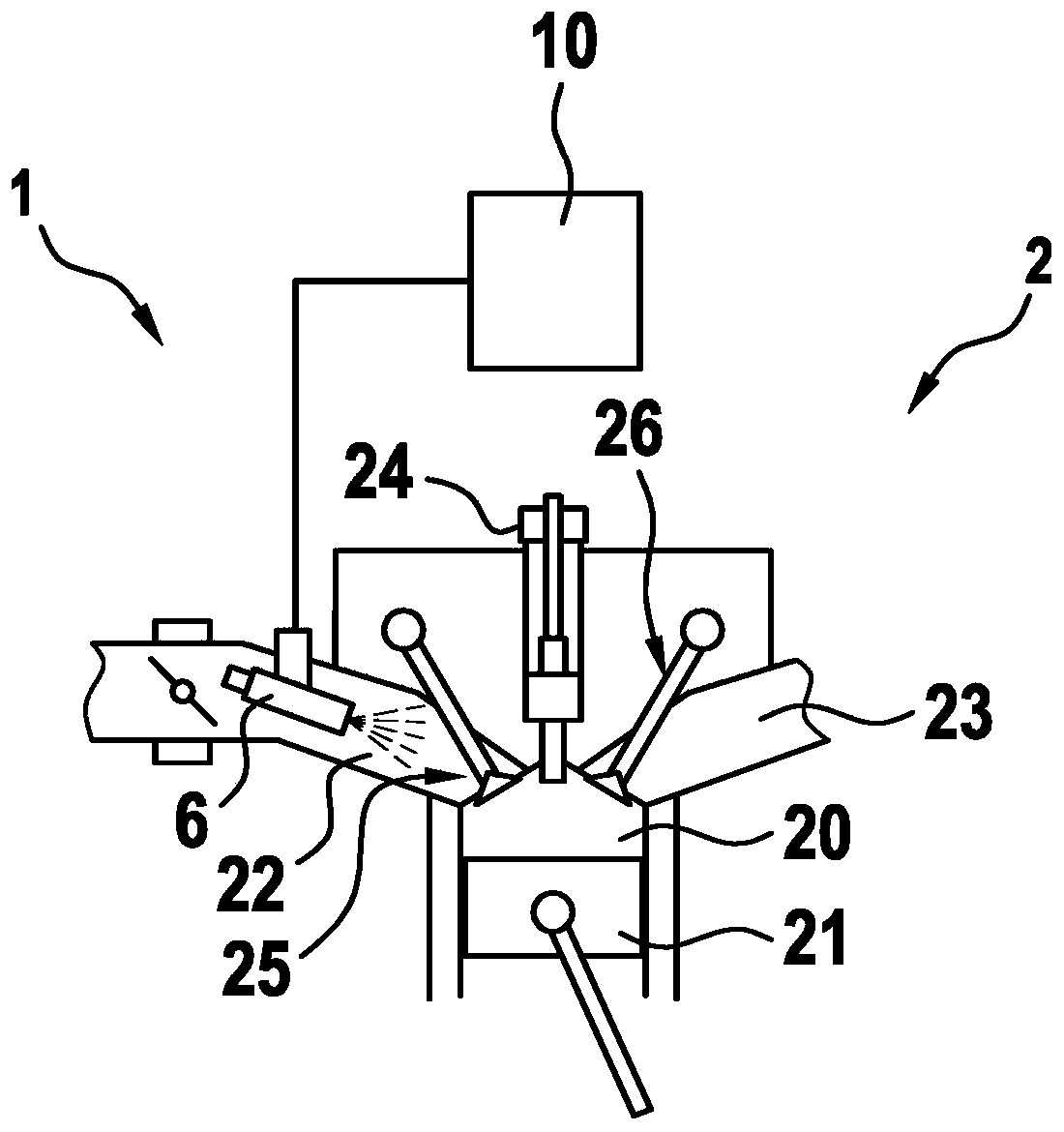

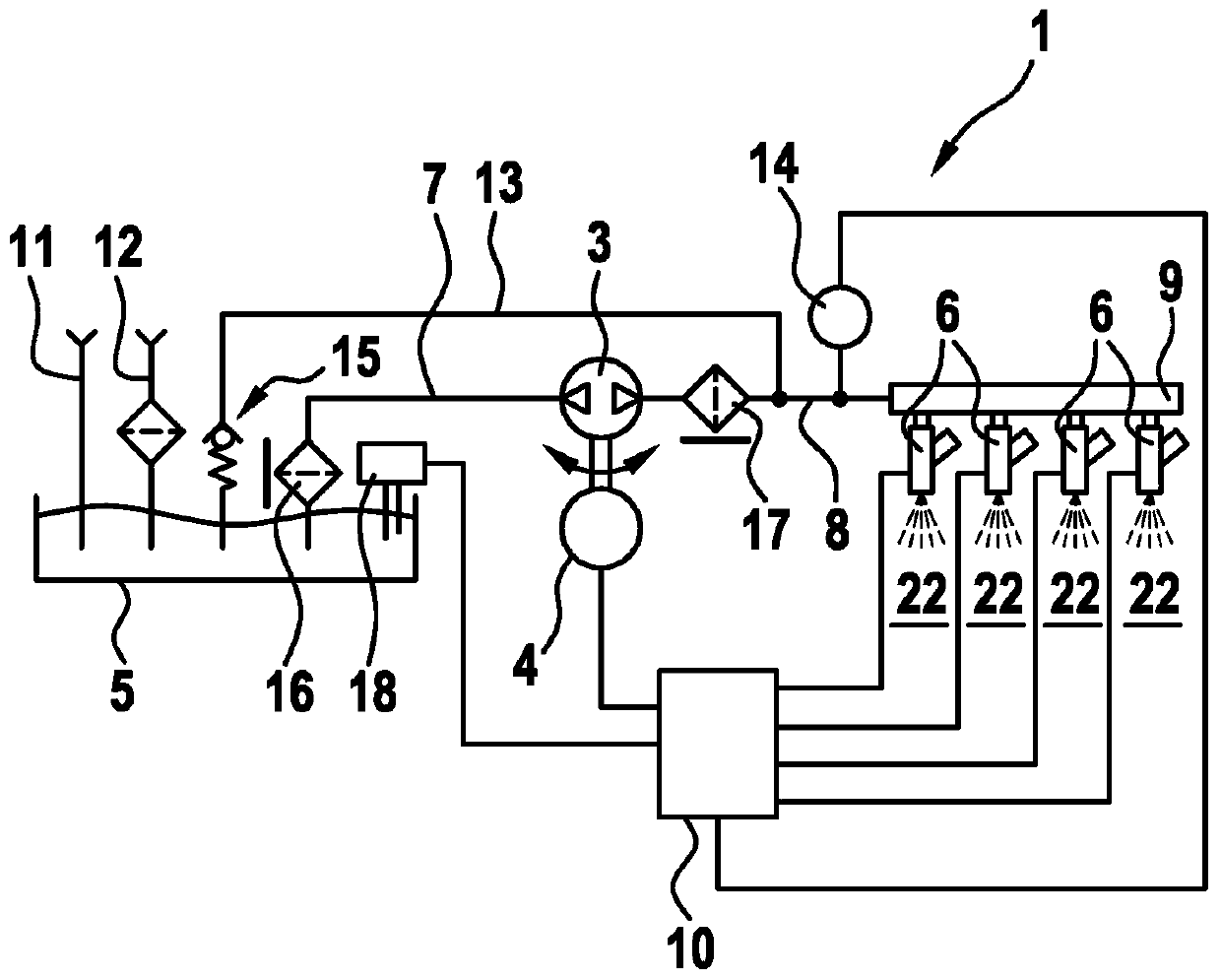

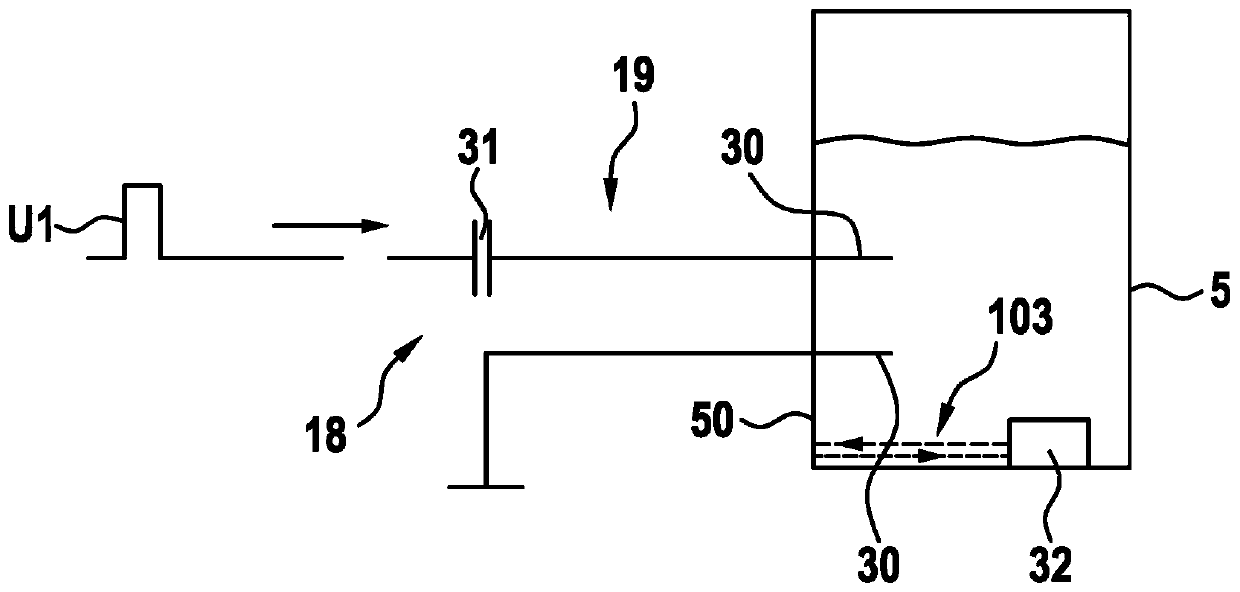

[0031] Refer below Figures 1 to 7 A water injection system 1 of an internal combustion engine 2 according to a preferred embodiment is described in detail. The internal combustion engine 2 is operated in particular according to the Otto principle and with direct gasoline injection.

[0032] exist figure 1 An internal combustion engine 2 with a plurality of cylinders and a part of a water injection system 1 according to the invention are schematically shown in . Each cylinder of the internal combustion engine 2 includes a combustion chamber 20 in which a piston 21 can reciprocate. Further preferably, each cylinder of internal combustion engine 2 includes an intake duct 22 via which air is supplied to combustion chamber 20 . The exhaust gas is discharged via the exhaust gas passage 23 . For this purpose, an intake valve 25 is arranged on the intake duct 22 and an exhaust valve 26 is arranged on the exhaust duct 23 . Furthermore, reference numeral 24 designates a fuel injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com