Connecting piece, connecting assembly, bending device and flexible screen terminal

A technology for connecting components and bending devices, which is applied in the direction of connecting components, identification devices, and friction-clamped detachable fasteners. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

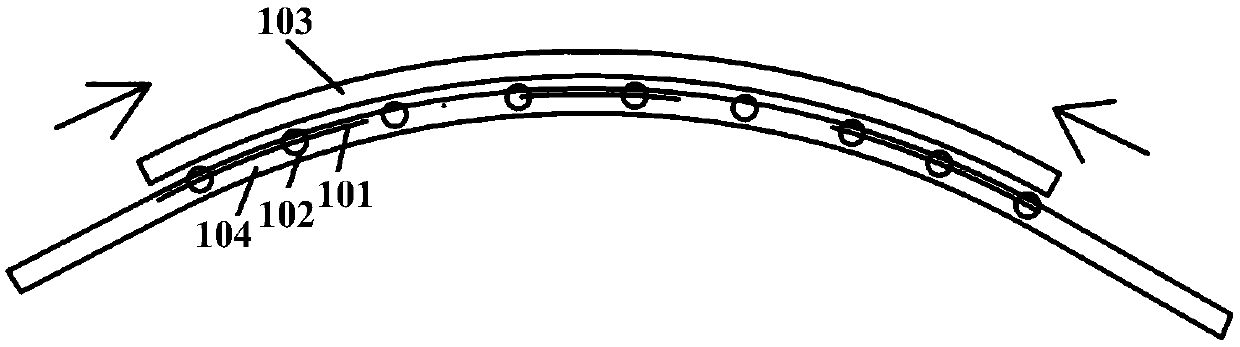

[0062] In order to solve the problem in the prior art that the flexible screen is directly bonded to the bending mechanism, which leads to the failure of the back glue due to the large slippage and shear delamination, which makes it difficult to bend and fold the flexible screen, this embodiment provides a connector. see Figure 4 As shown, the connector 40 includes a through hole 401 and a buckle 402, wherein the through hole 401 is arranged at one end of the connector 40, one end of the connector 40 is lower than the other end of the connector 40, and the buckle 402 is arranged on the connector 40 The other end is used to engage with the through hole of another connector. It is worth noting that the length direction of the connector referred to in this embodiment is as follows: Figure 4 direction indicated by the arrow, and it is also worth noting that, Figure 4 Shown is a specific connector, the invention is not limited to Figure 4 The connectors shown can be flexibly...

no. 2 example

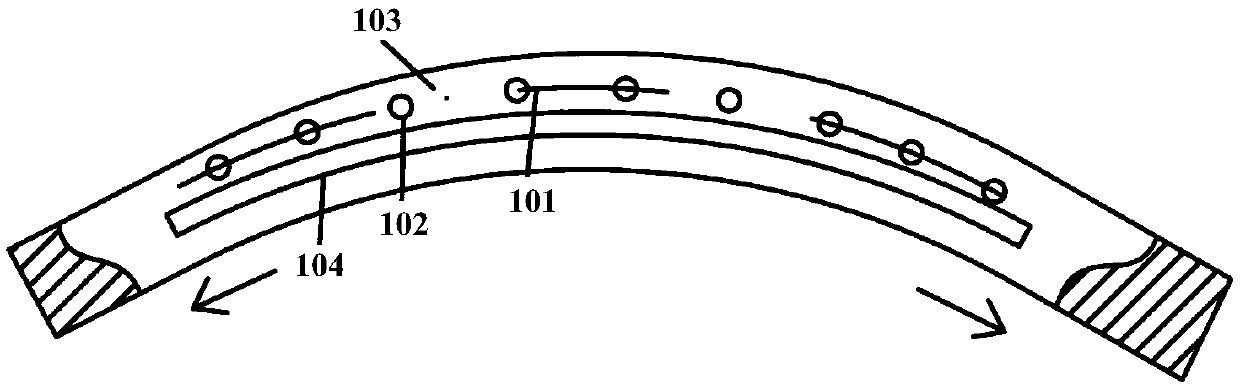

[0079] In order to better understand the present invention, this embodiment is described with a specific connection assembly, see Figure 10 As shown, the connecting assembly 100 includes two connecting pieces, namely a first connecting piece 1001 and a second connecting piece 1002, wherein, through holes are provided at both ends of the first connecting piece 1001, and at the same time along the first connecting piece One of the through holes in the length direction of 1001 is provided with buckles on the opposite inner wall; through holes are also provided at both ends of the second connector 1002, and one of the through holes along the length direction of the second connector 1002 is opposite to each other. Buckles are provided on the inner wall; in this embodiment, the upper surfaces of the first connecting part 1001 and the second connecting part 1002 are sprayed with a paint whose friction coefficient is lower than a preset friction coefficient threshold value, specifical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com