Turnover device, convenient in taking and placing, for automobile chassis part

A technology of automobile chassis and load-carrying frame, which is applied in the direction of tool storage device, workshop equipment, manufacturing tools, etc. It can solve the problems that the turnover device does not have mobility, it is inconvenient to push the turnover device, and it cannot be effectively isolated, so as to achieve easy access , to avoid mutual collision, to avoid the effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

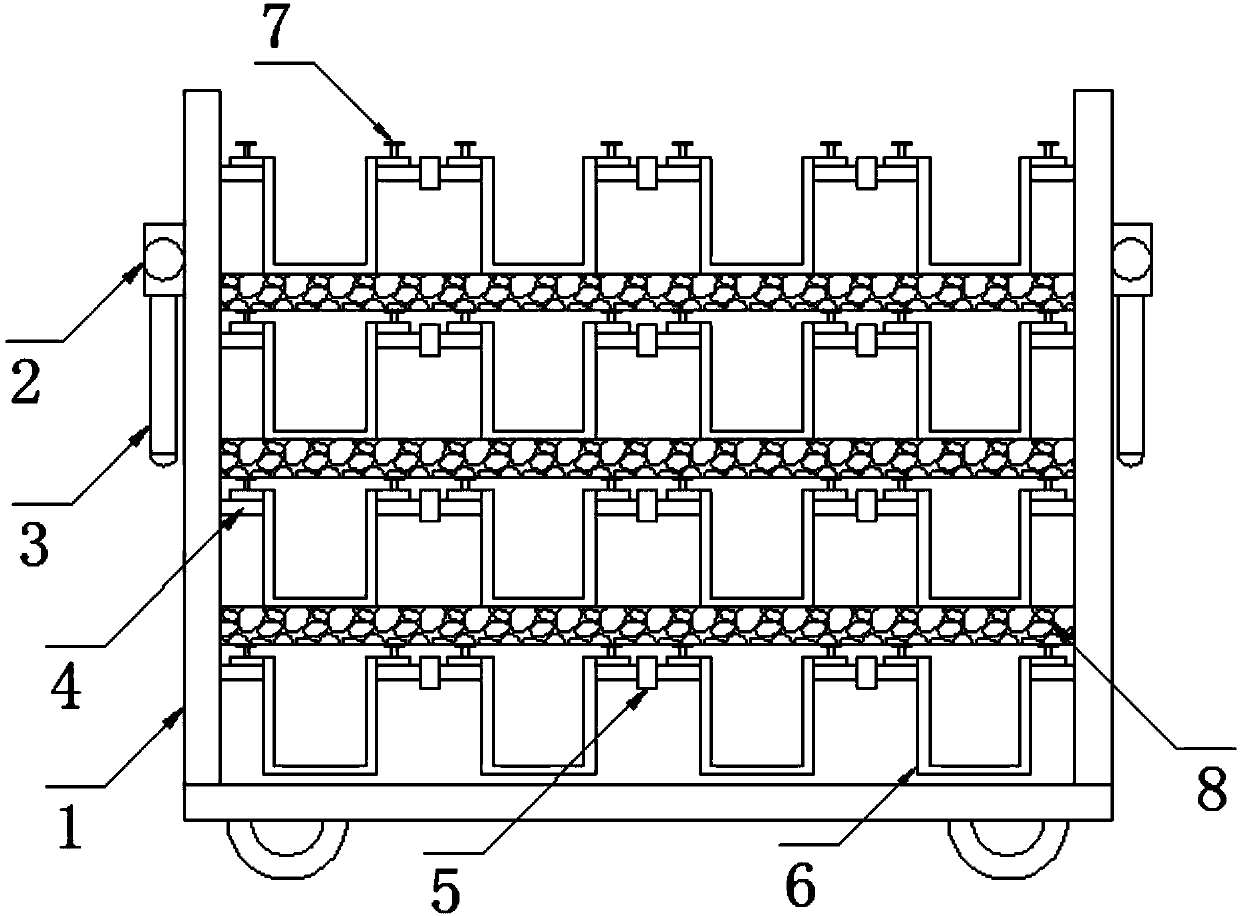

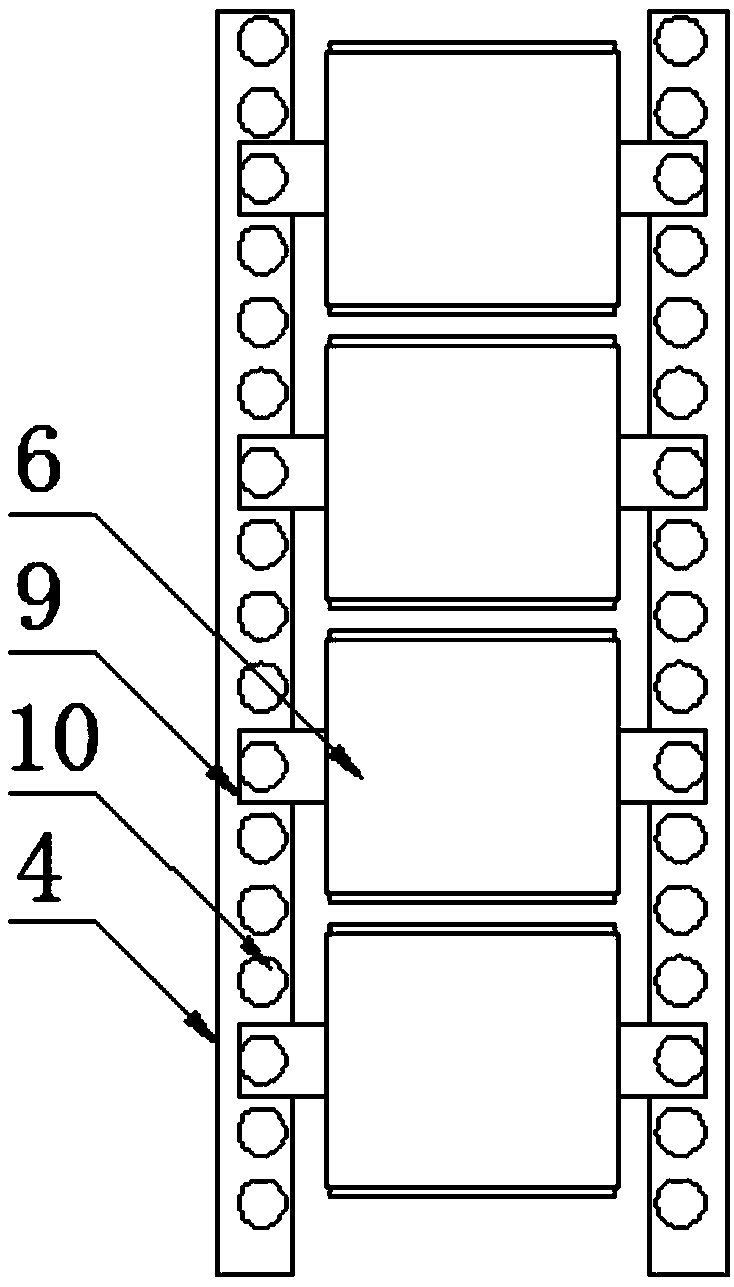

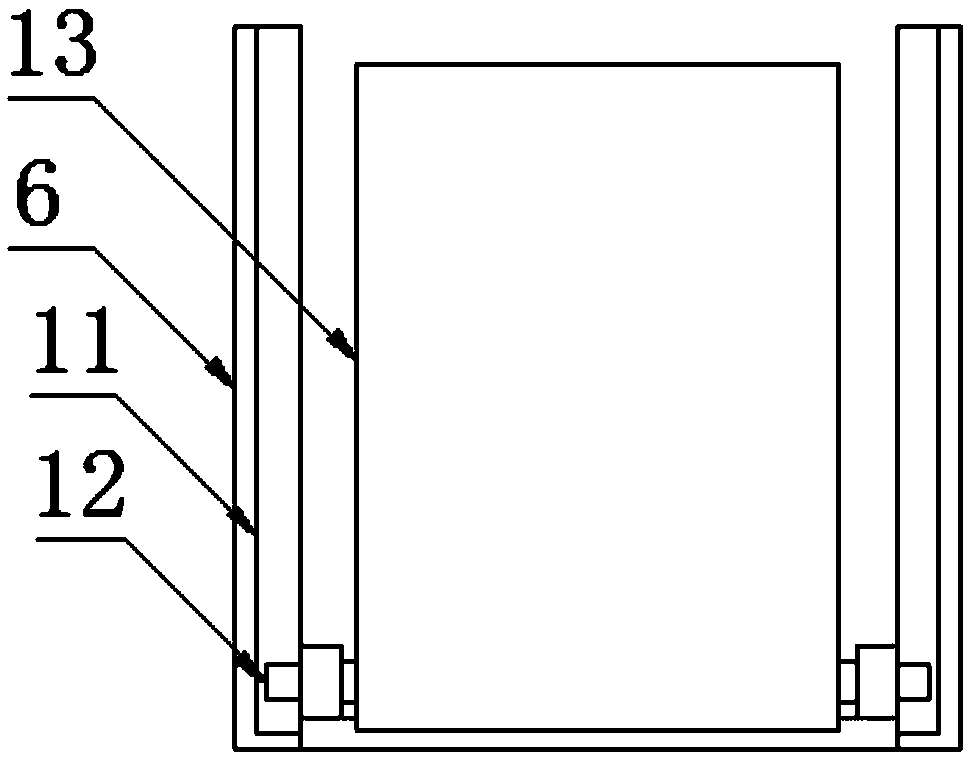

[0024] Embodiment: when using the turnover device to store and carry the chassis parts of the automobile, at first classify according to the model size of the chassis parts of the automobile. The block 12 slides in the chute 11, so that the baffle 13 can be plugged into the bearing frame 6, and then the baffle 13 is turned over by the pin shaft, so that the baffle 13 can be clamped on the bearing frame 6 on the other side, thus completing The combination of adjacent bearing frames 6, the bearing frame 6 is lapped on the support plate 4 through the hanging plate 9, the position of the bearing frame 6 can be easily adjusted, and the position of the bearing frame 6 can be easily adjusted by inserting the limit rod 7 in the limit hole 10. The bearing frame 6 is fixed on the support plate 4, and then the foam pad 8 is laid on the top of the bearing frame 6, and the chassis parts of the automobile are continued to be placed in the upper bearing frame 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com