Dust removing system and color selector with same

A technology of dust removal system and color sorter, which is applied in the field of color sorter, can solve the problems of affecting the color sorting effect, low wind pressure in the middle receiving bin, and inability to achieve effective dust removal, etc., so as to reduce the difficulty of color sorting and improve the accuracy of color sorting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

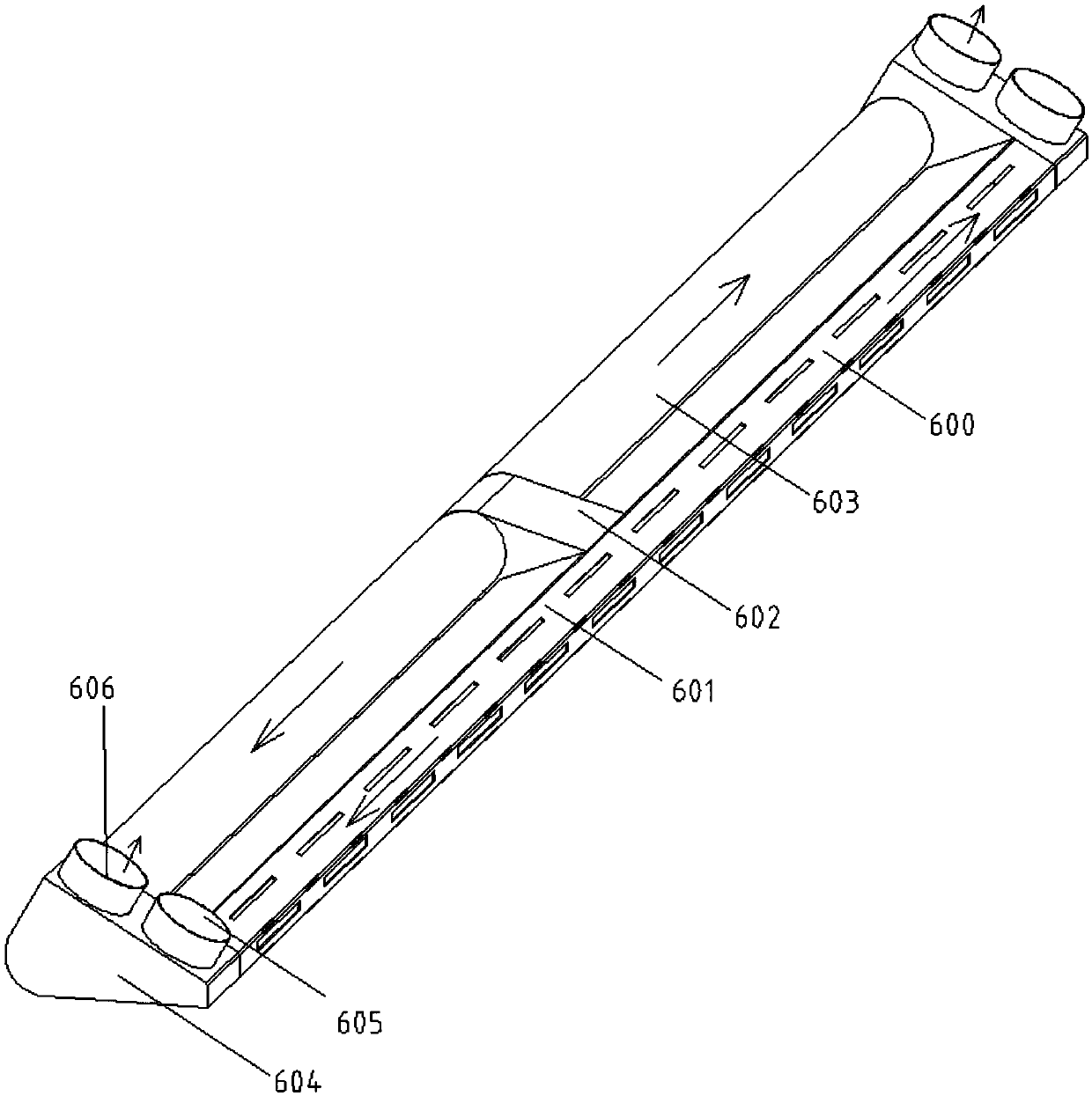

[0019] refer to figure 1 As shown, this embodiment provides a dust removal system, including a first suction box 601, a connecting frame 602, a second suction box 603, a bracket 604, a first suction nozzle 605, and a second suction nozzle 606. The middle part of the first suction box 601 and the middle part of the second suction box 603 are connected by a connecting frame 602, the end of the first suction box 601 and the end of the second suction box 603 are connected by a bracket 604, the first The suction box 601 and the second suction box 603 are arranged side by side, the first suction box 601 is provided with a horizontal first suction cavity, and the second suction box 603 is provided with a horizontal second suction cavity. The connecting frame 602 is provided with an intermediate connecting air chamber that communicates with the first air suction chamber and the second air suction chamber. The first air suction box 601 is uniformly provided with a plurality of air suct...

Embodiment 2

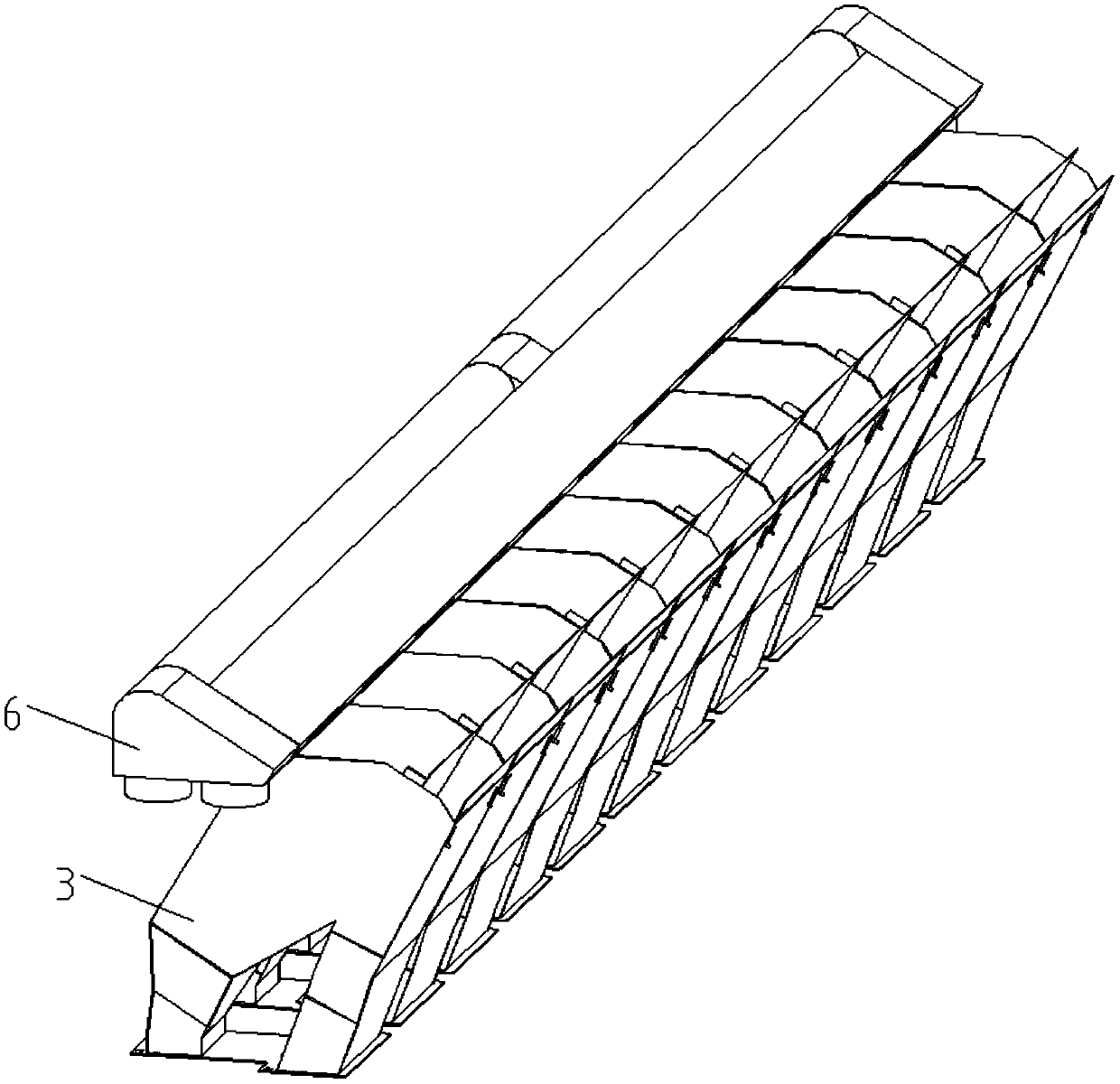

[0023] refer to figure 2 As shown, this embodiment provides a color sorter, including a discharge device 3, and the upper end of the discharge device 3 is also provided with the dust removal system 6 described in Embodiment 1.

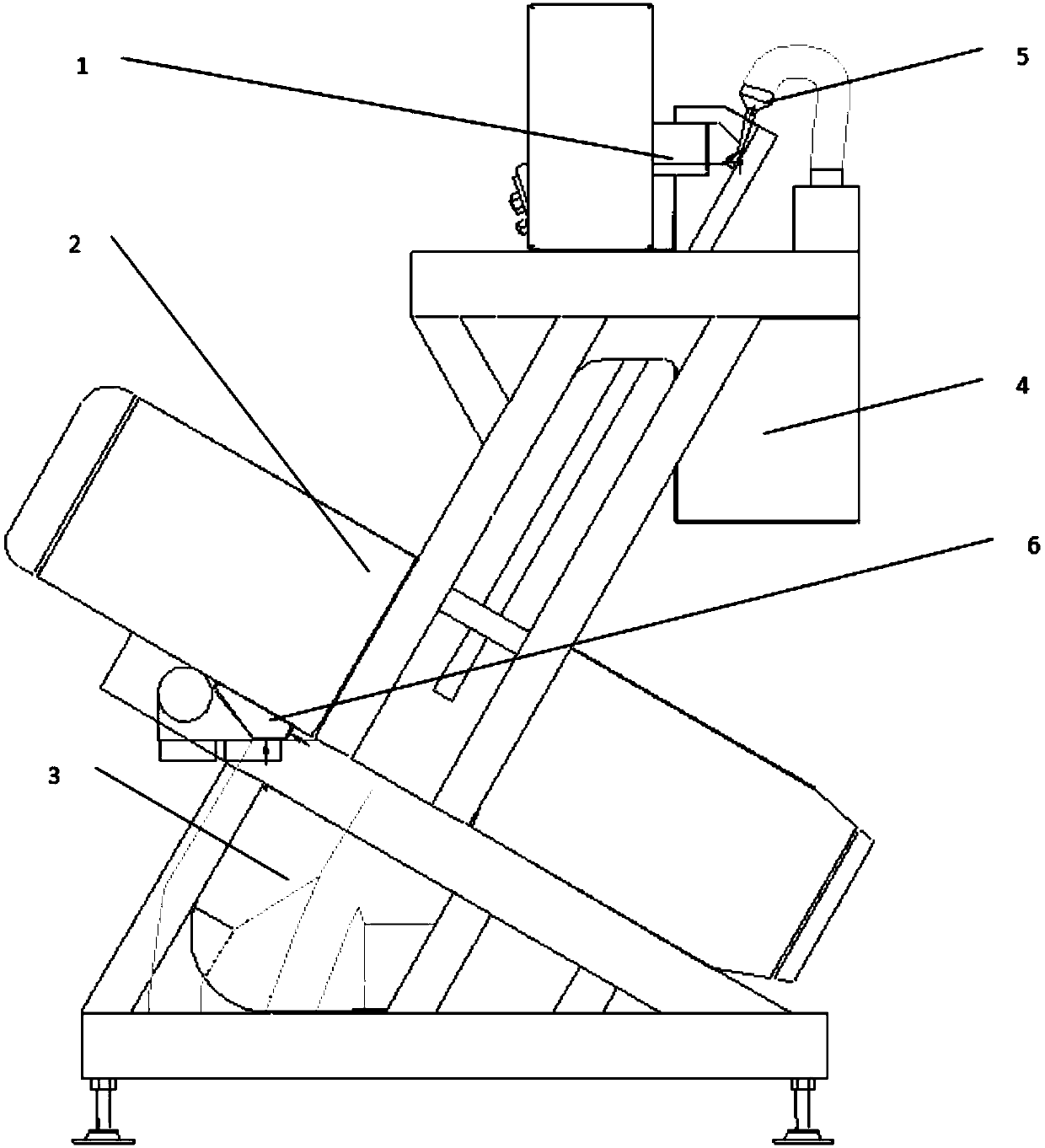

[0024] refer to image 3 As shown, the color sorter includes a feeding device 1 , a sorting and identifying device 2 , an electric control device 4 and a feeding dust removal device 5 , and the feeding dust removal device 5 is arranged at the feeding device 1 .

[0025] The suction slot 600 on the dust removal system 6 corresponds to the discharge bin in the discharge device 3, which can ensure that the dust at the discharge bin is well sucked.

[0026] The working principle of the dust removal system of this embodiment applied in the color sorter is: it can remove the floating dust generated by the vibrating feeder outlet (that is, the inlet of the discharge bin) from the feed source, reduce the difficulty of color sorting, improve the accuracy of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com