Novel BOSA shell-LD press fitting structure and press fitting method

A technology of press-fitting structure and shell, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high personnel requirements and high labor intensity, so as to reduce the dependence of personnel, facilitate centralized management, and optimize press-fitting. The effect of the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

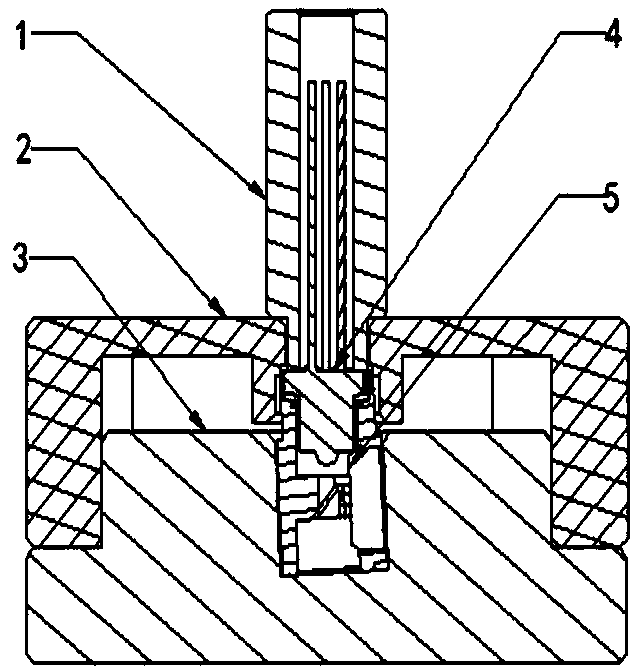

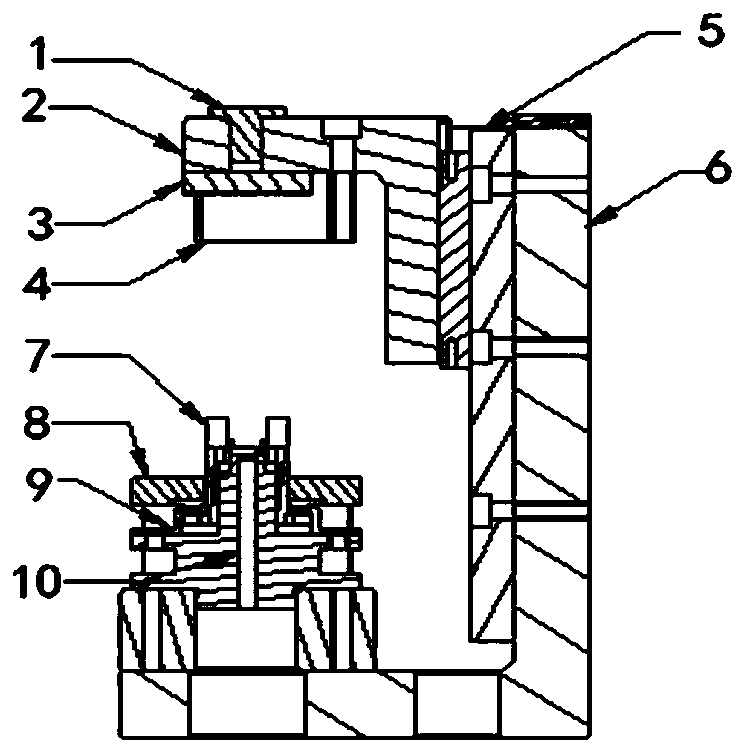

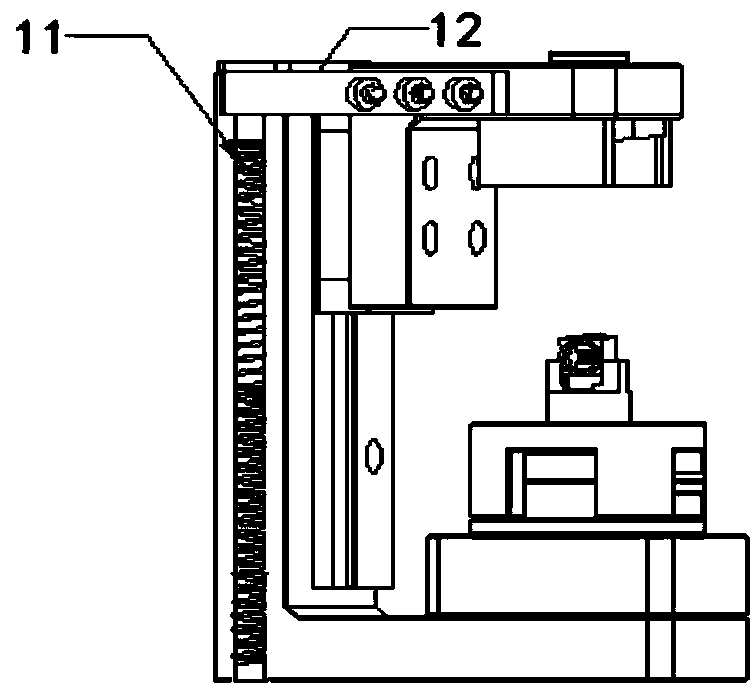

[0038] 1. A new type of BOSA shell-LD press-fit structure, such as figure 2 , image 3 As shown, the components are represented as follows:

[0039] serial number

name

serial number

name

1

pressure block

7

Elastic sleeve

2

Lower arm

8

Height limit base

3

Press-fit slope

9

elastic cover

4

height limit block

10

pressure head

5

Linear guide

11

return spring

6

L-shaped base

12

Reset link

[0040] in:

[0041] Return spring 11 is placed inside the side of L-shaped base 6, linear guide rail 5 is set in the vertical direction of L-shaped base 6, lower pressing arm 2 is set on linear guide rail 5, pressure bearing block 1 is placed on the lower pressing arm 2, and The reset link 12 is fixed on the side of the pressing arm 2, and the pressing inclined surface 3 and the height limit block 4 are fixed under the lower pressing arm 2; the pressing head 10 is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com