Sensor connecting assembly and track transportation system

A technology for connecting components and sensors, which is applied in locomotives, railway signals and safety, etc., and can solve problems such as deviation of the sensing range and failure of the sensor 3' to achieve the expected effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

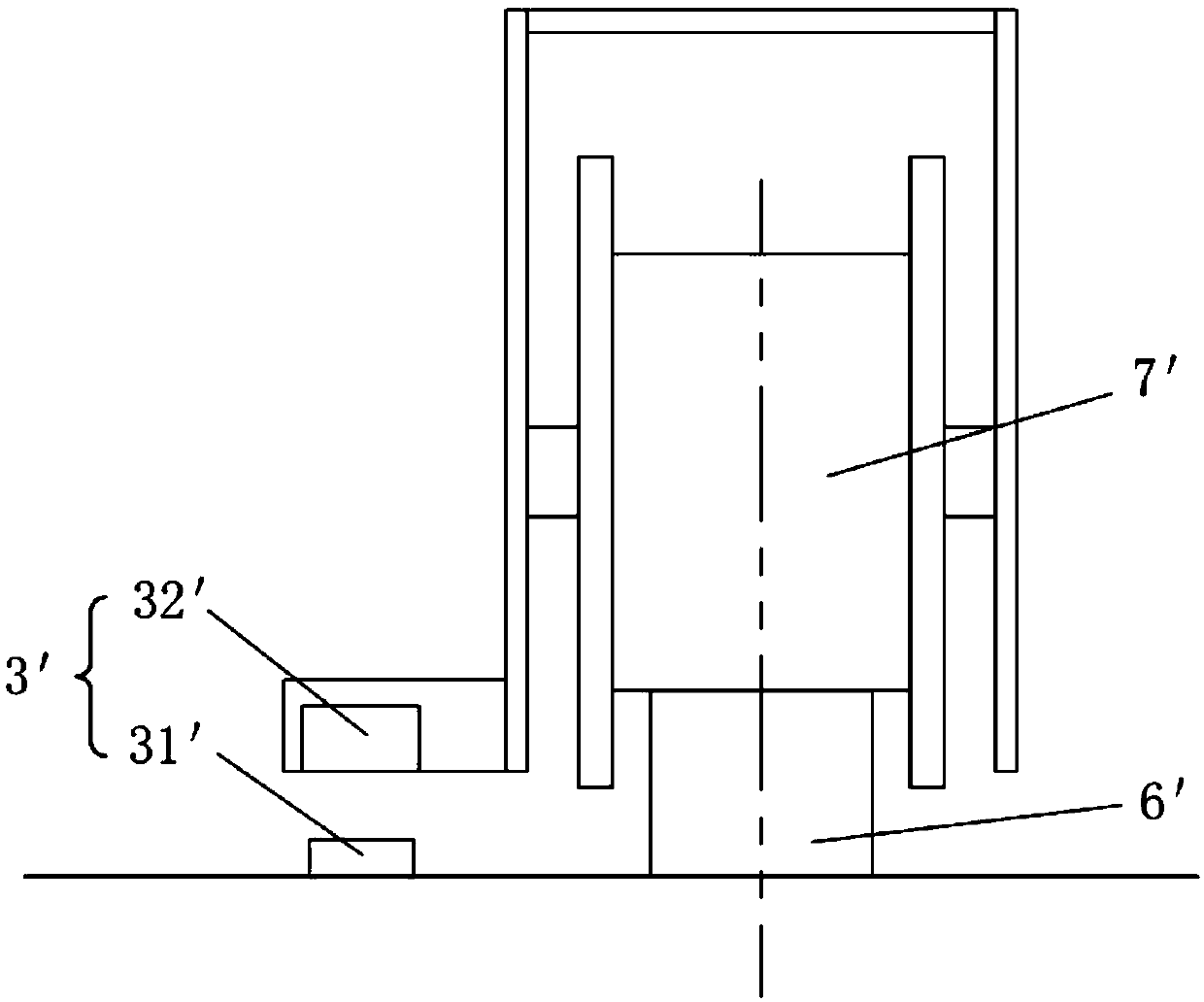

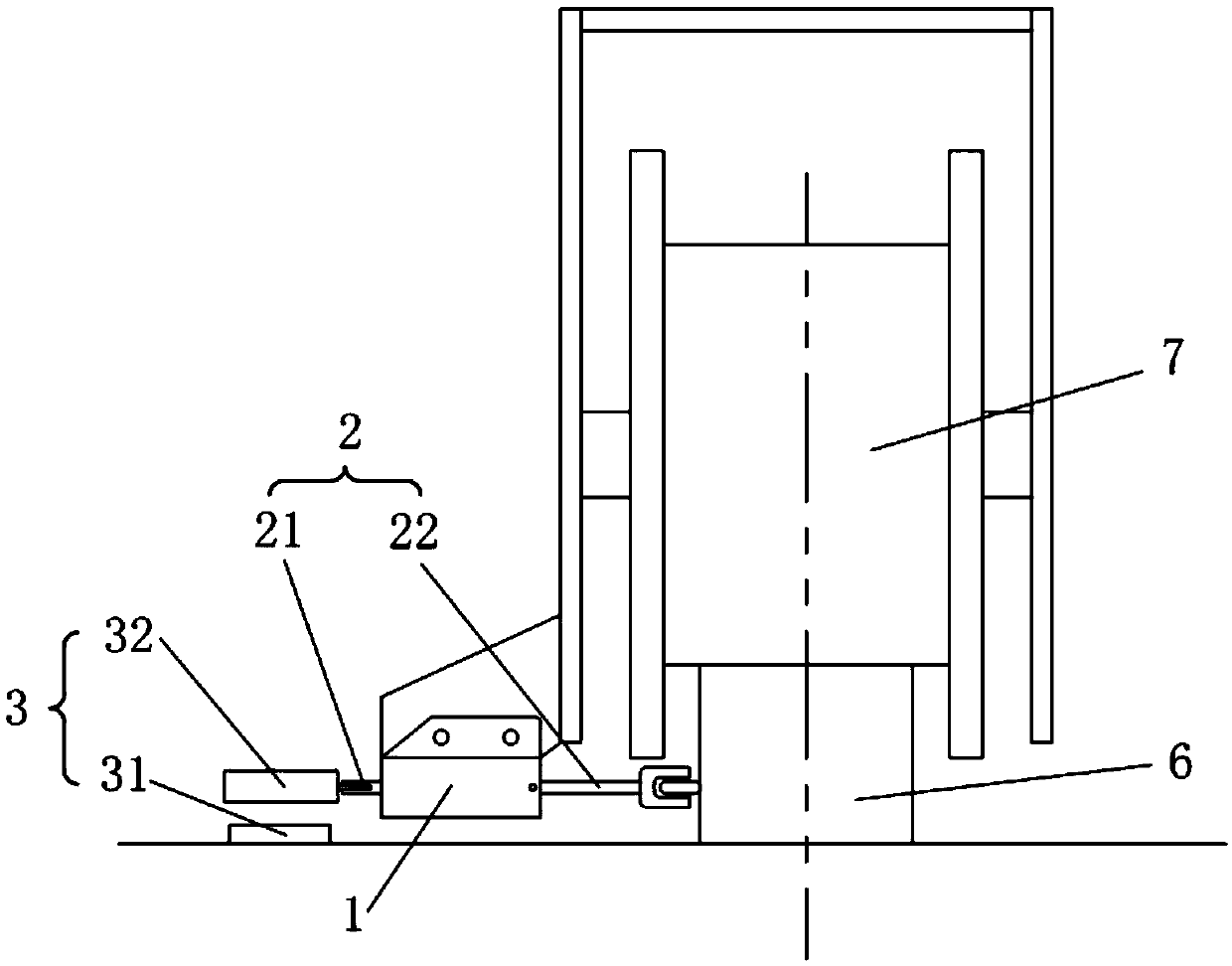

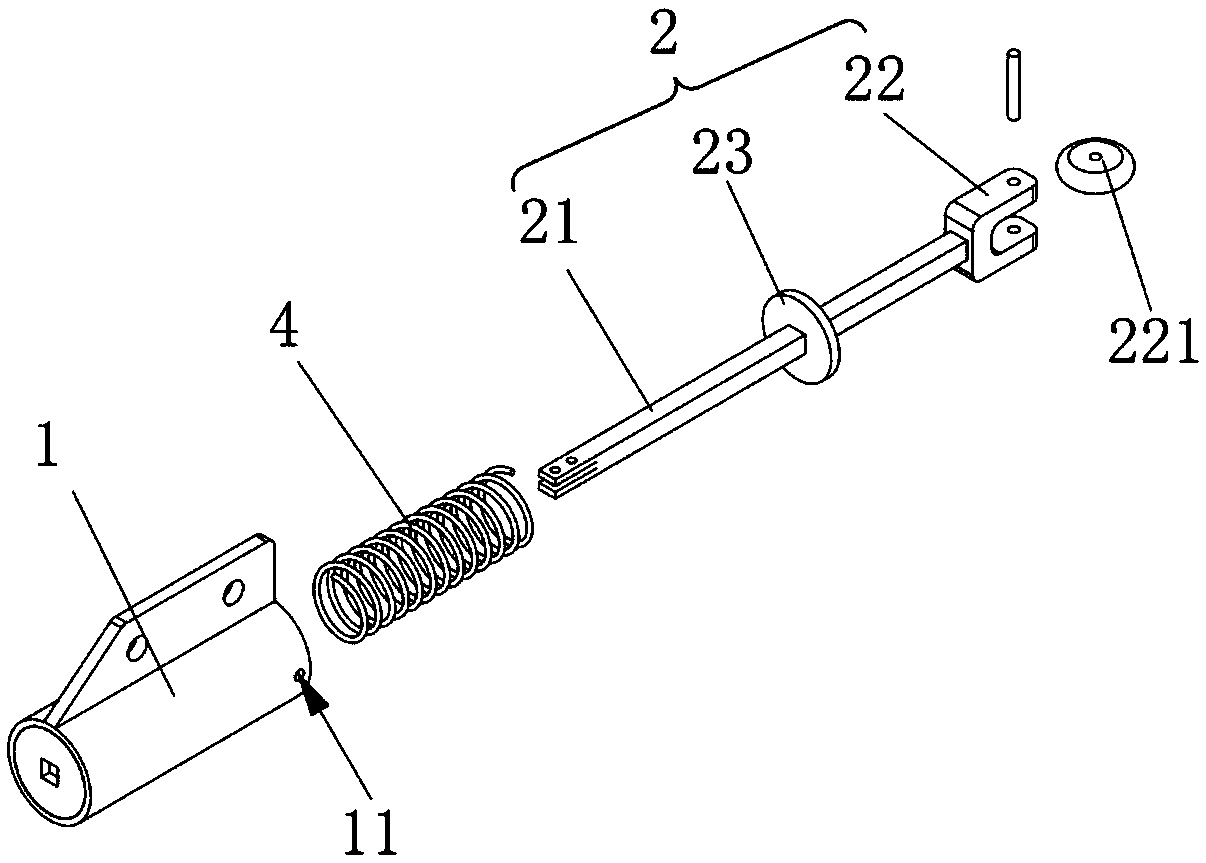

[0036] Such as figure 2 As shown, this embodiment provides a rail transportation system, including a rail 6 and a running vehicle 7 running along the rail 6 . In order to detect and control the running process of the running vehicle 7 along the track 6, a sensor 3 can be installed in the track transportation system. The sensor 3 may include a positioning end 31 and a measuring end 32. When the vehicle 7 runs to a preset position, the positioning end 31 is within the detection range of the measuring end 32, and the measuring end 32 can output a signal. The sensor 3 can be a magnetic sensor, the measuring end 32 can be a magnetic field detection end, and the positioning end 31 can be a magnetic block; certainly in other embodiments, the sensor 3 can also be a photoelectric sensor, the positioning end 31 can be a transmitter, and the measuring end 32 can be a magnetic block. It can be a receiver; and other sensors 3 capable of realizing the detection function can be adopted. T...

Embodiment 2

[0047] During the running of the trolley 7 along the track 6, the track 6 is prone to wear and tear, so that the surface of the track 6 has unevenness such as pits. When the guide wheel 221 abuts against the rail 6 , affected by the surface quality of the rail 6 , a movement deviation perpendicular to the extending direction of the rail 6 occurs. In order to solve this problem, this embodiment provides a rail transportation system and a sensor connection assembly. The rail transport system differs from Embodiment 1 in that, as Figure 5-6 As shown, the rail transportation system further includes a guide rail 5 , the extension direction of the guide rail 5 is parallel to the extension direction of the rail 6 . The guide wheel 221 of the sensor connection assembly abuts against the guide rail 5 and can roll along the rail 6 .

[0048] The guide rail 5 and the track 6 can be arranged at both ends of the body 1 . Correspondingly, both the guide wheel connection part 22 and the ...

Embodiment 3

[0050] This embodiment provides a rail transportation system and a sensor connection assembly. The difference between this rail transport system and Embodiment 2 is that the spring 4 is selected as a tension spring, the guide rail 5 is arranged between the body 1 and the rail 6 , and the abutment surface of the guide wheel 221 and the guide rail 5 faces the body 1 .

[0051] Such as Figure 7-Figure 8 As shown, when the sensor connection assembly is installed on the running car 7, the spring 4 is in a stretched state, and the spring 4 is stretched to store force, so as to drive the slide bar 2 to drive the guide wheel 221 to abut against the rail 6.

[0052] When the running car 7 deviates from the side perpendicular to the track 6 toward the side where the sensor connection assembly is installed, the body 1 of the sensor connecting assembly deviates along with the running car 7 in this direction, causing the distance between the body 1 and the track 6 to increase, and the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com