Infusion tube pressure sensor

A pressure sensor and infusion tube technology, which is applied in the direction of instruments, drug devices, hypodermic injection devices, etc., can solve the problems that affect the infusion pressure sensor's sensing accuracy, correction, and the change of reaction force time and temperature cannot be accurately calculated, and achieve structural Simple and compact, accurate test results and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

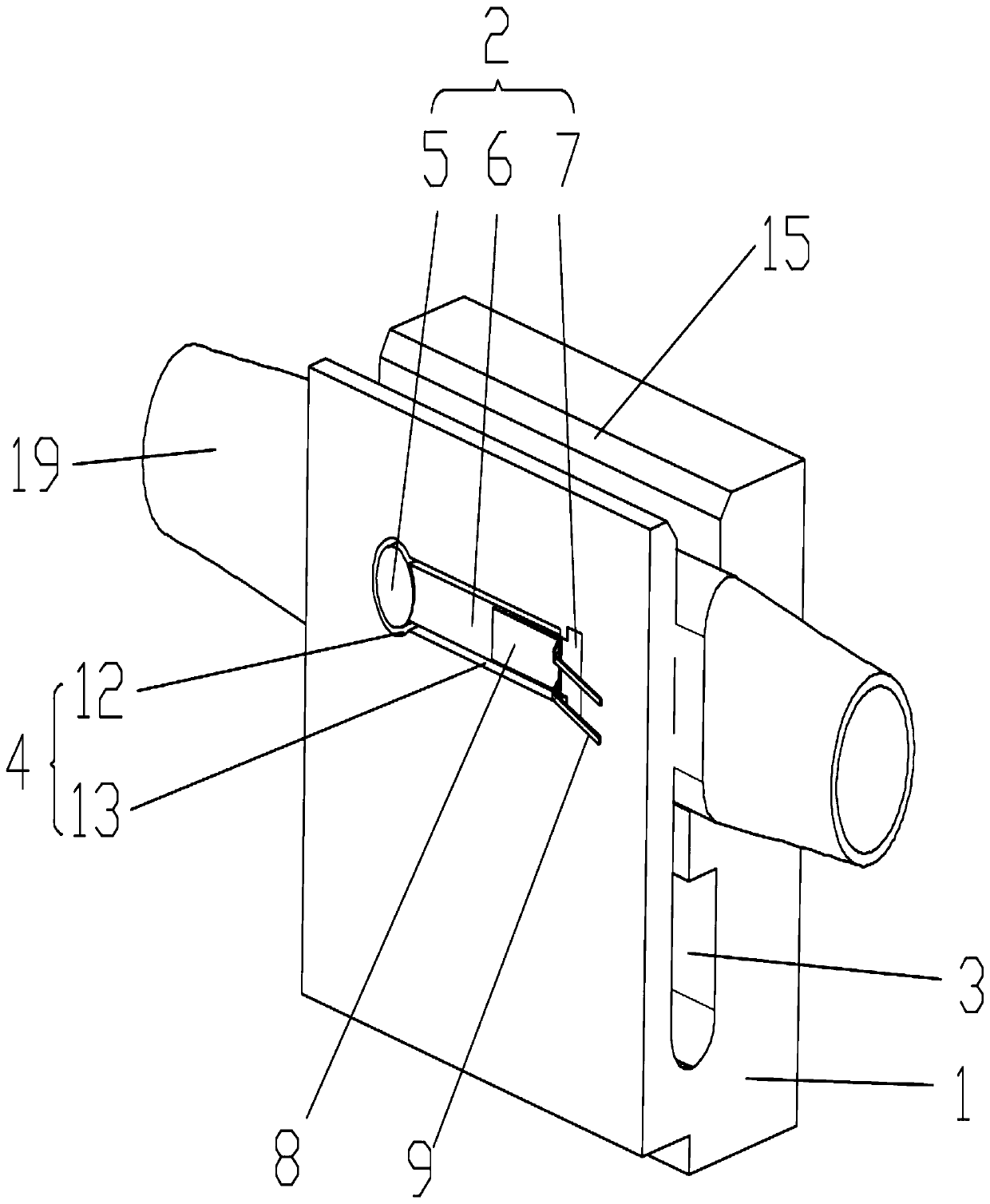

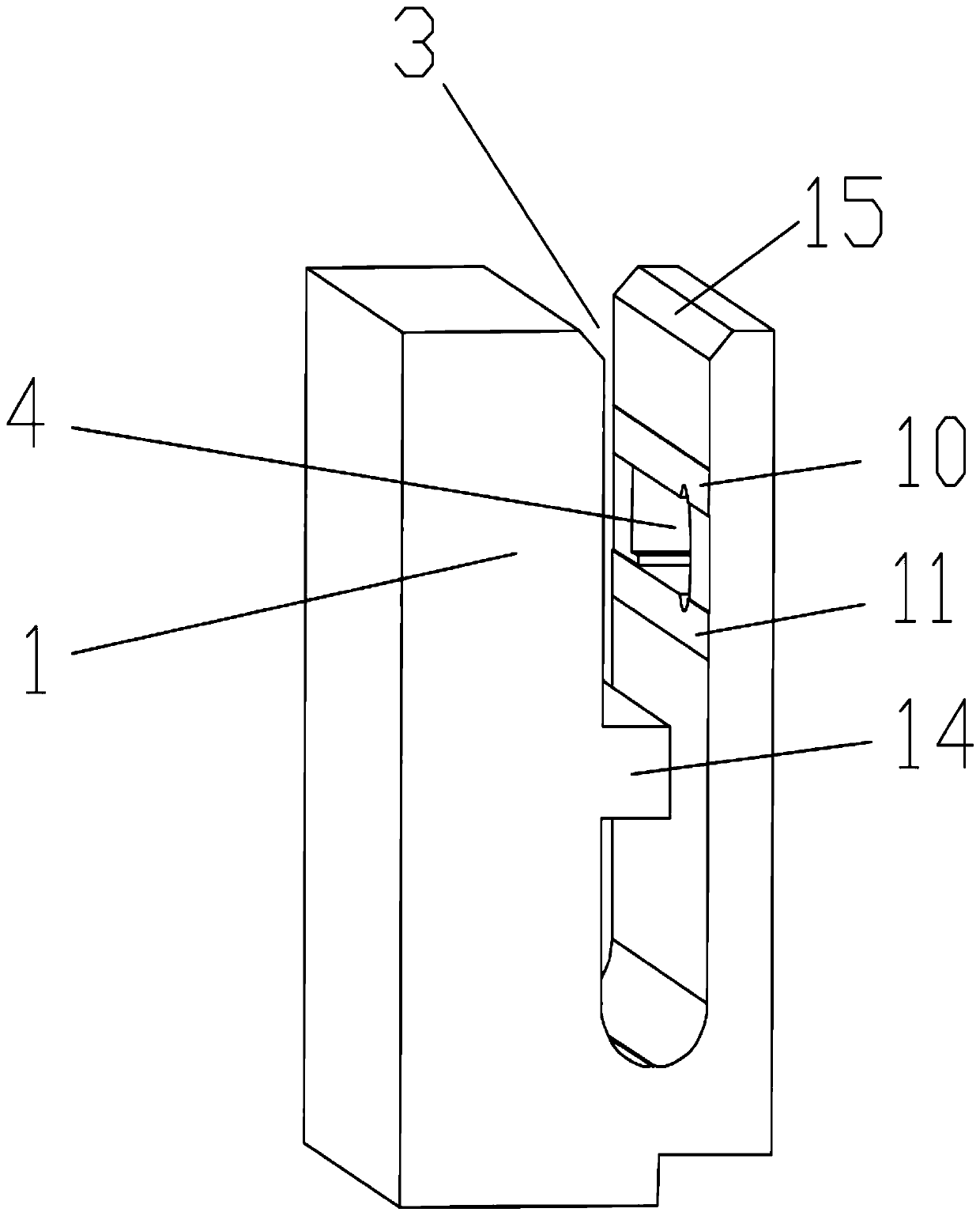

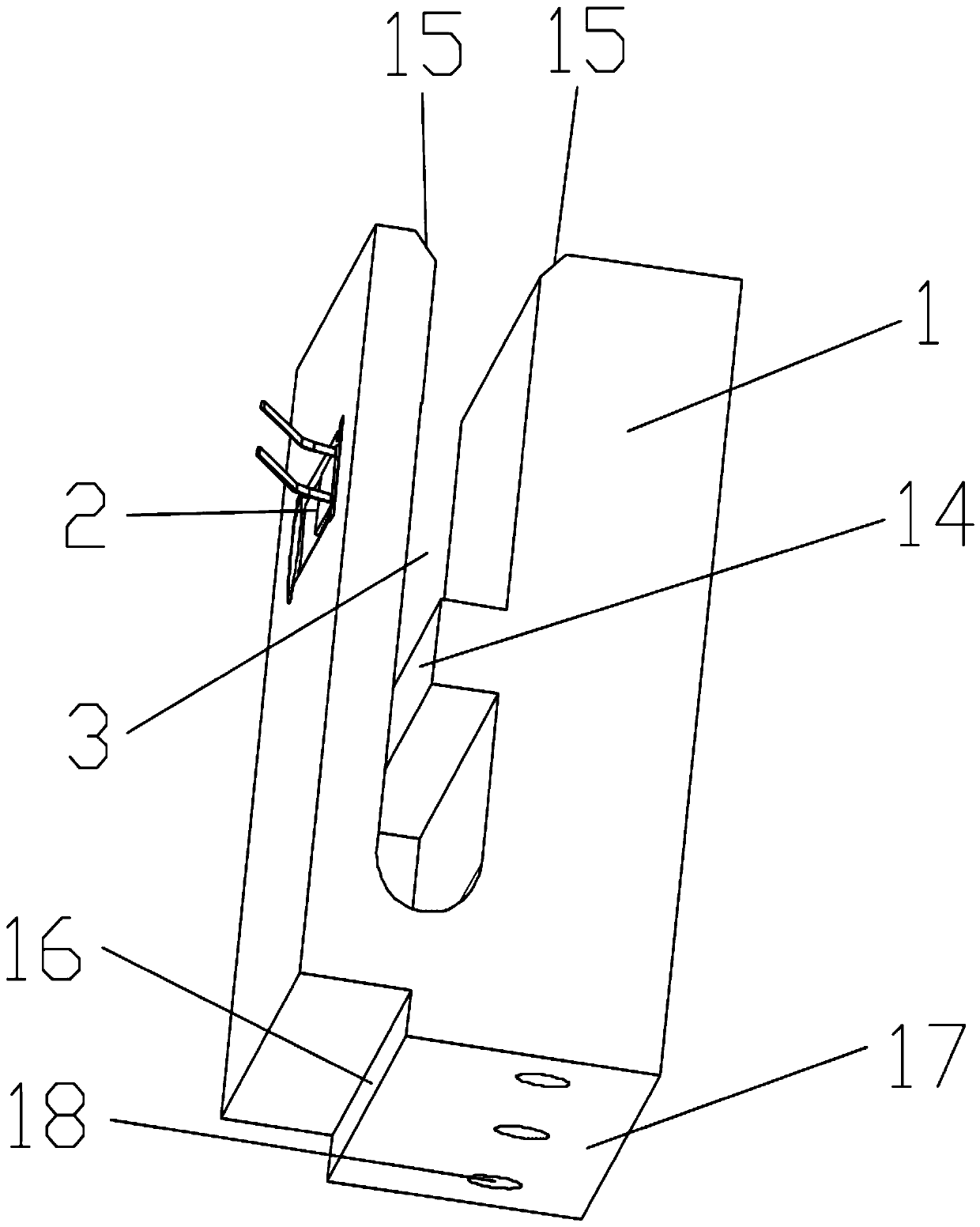

[0019] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0020] In order to facilitate a unified review of the various reference signs in the drawings of the specification, the unified description of the reference signs appearing in the drawings of the specification is as follows:

[0021] 1 is the fixed seat, 2 is the induction component, 3 is the infusion tube groove, 4 is the induction groove, 5 is the induction head, 6 is the induction arm, 7 is the induction fixed block, 8 is the strain gauge, 9 is the signal output line, 10 is the Upper support surface, 11 is the lower support surface, 12 is a round hole, 13 is a rectangular hole, 14 is a support platform, 15 is a chamfer, 16 is a positioning surface, 17 is a fixing surface, 18 is a screw hole, 19 is an infusion tube, 20 is the center of the outer wall of the infusion tube, 21 is the upper end of the outer wall of the infusion tube, and 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com