Hose packaging structure

A packaging structure and hose technology, applied in the direction of packaging, transportation and packaging, rigid containers, etc., can solve the problems that the bending part of the water pipe is easy to get stuck and kink, inconvenient to use, and poor water flow, etc., to solve the problem of hard water pipes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

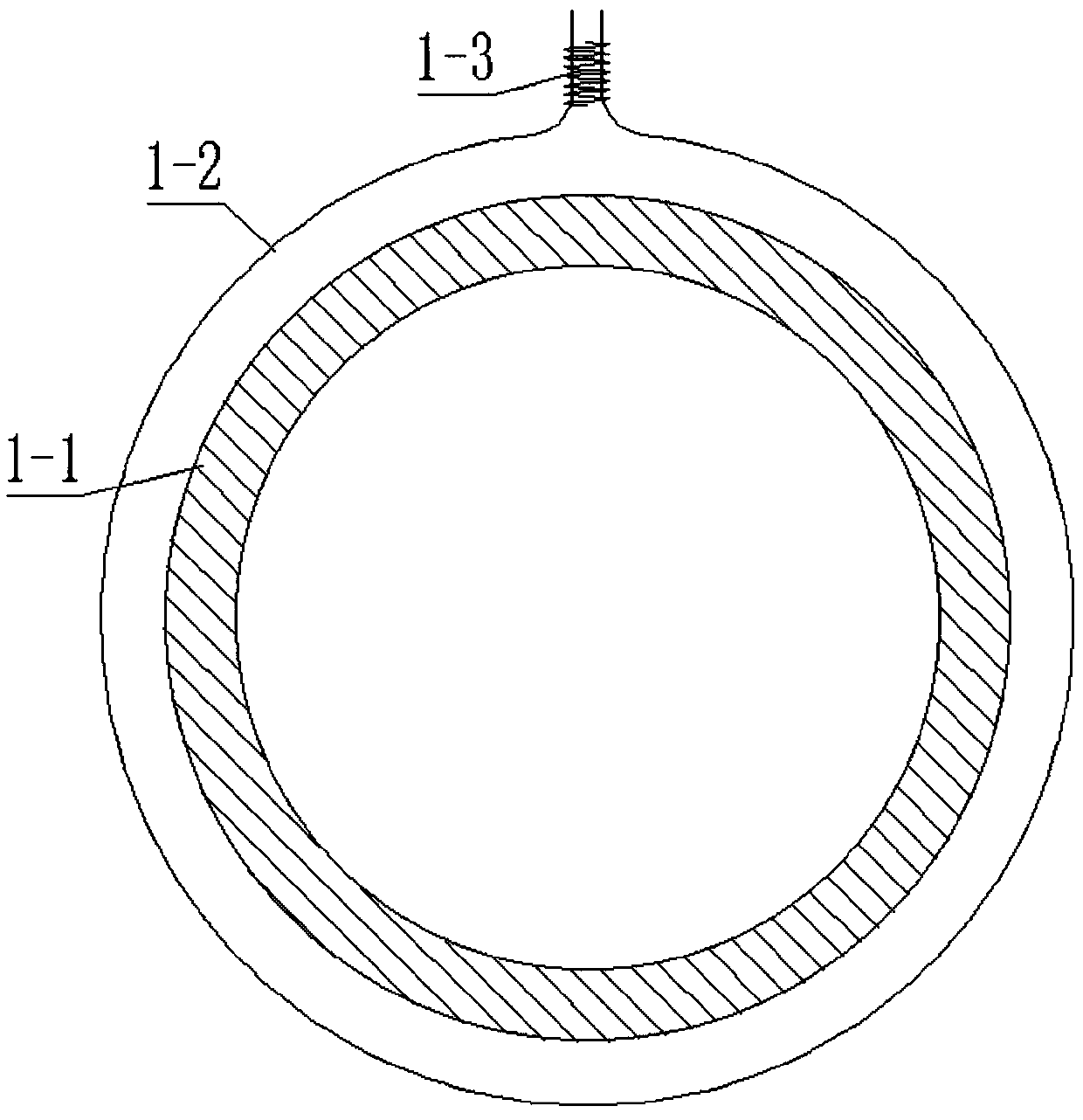

[0019] Combine below Figure 1-2 Describe this embodiment, the present invention relates to the field of hose packaging structure, more specifically a hose packaging structure, including a hose body 1-1, a packaging layer 1-2 and a seam portion 1-3, which can provide a This kind of hose packaging method can solve the problem that the packaged water pipe is hard.

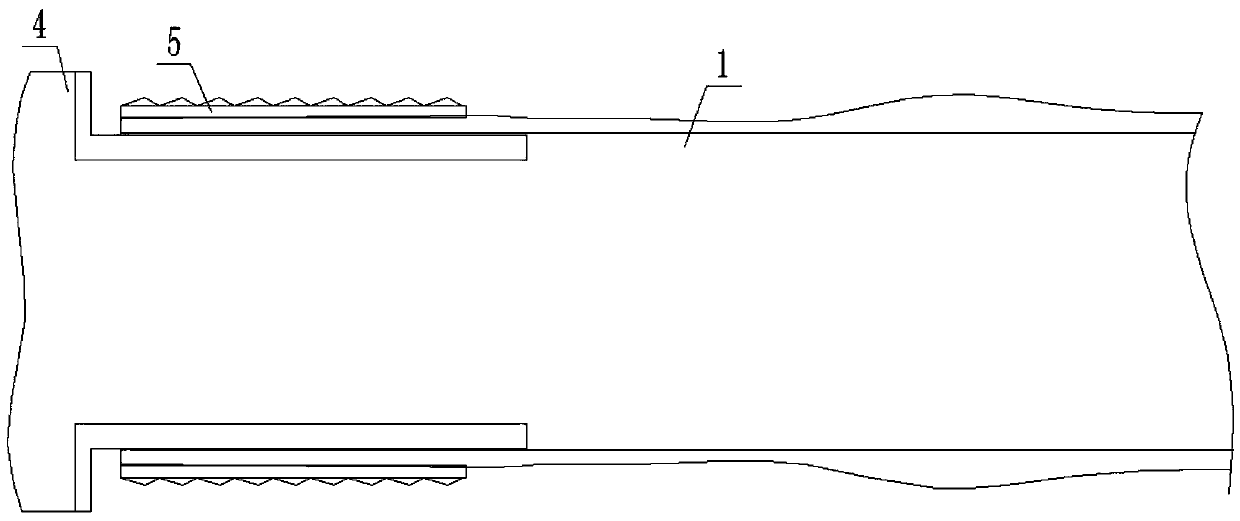

[0020] The tube body 1 is provided with a hose body 1-1, a packaging layer 1-2 and a seam portion 1-3, the packaging layer 1-2 is placed at the outer end of the hose body 1-1, and the packaging layer 1- 2 are connected by seams 1-3; the connecting piece 4 is provided with multi-step anti-slip embossing, the fixing piece 5 is fastened on the connecting piece 4, and the pipe body 1 is located between the connecting piece 4 and Between the fixing parts 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com