A kind of mg-re series magnesium alloy and its preparation method and application

A magnesium alloy and alloy technology, applied in the field of medical metal materials and its preparation, can solve problems such as distortion, induced cancer, human allergy and inflammatory response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1, preparation cast state Mg-RE series magnesium alloy

[0067] The test raw materials are pure Mg (99.9wt.%) and common industrial grade rare earth (TREM>99.5wt.%) as raw materials, according to the mass ratio in the following table:

[0068] Types of REs RE content Mg content Eu 1% margin Eu 3% margin Tb 1% margin Tb 5% margin Dy 1% margin Dy 10% margin Er 1% margin Er 10% margin T m 1% margin T m 10% margin Yb 1% margin Yb 3% margin Lu 1% margin Lu 10% margin

[0069] mixed, in CO 2 +SF 6 Under the protection of the atmosphere, heat up to 50-100°C higher than the melting point of the alloy, and keep the temperature for 20 minutes with stirring. The liquid metal is poured into a graphite mold preheated to 250°C, cooled to room temperature with the furnace, and then released from the furnace to obtain a Mg-RE magnesium alloy.

[...

Embodiment 2

[0071] Embodiment 2, preparation extruded state Mg-RE series magnesium alloy

[0072] First, the as-cast Mg-RE series magnesium alloy ingot is prepared according to the steps in Example 1 of the present invention, the Mg-RE series alloy bar is prepared by extrusion, radial extrusion is adopted, the ingot is kept warm for 4 hours, and the holding temperature 450°C or 500°C, water-cooled for later use. The extrusion temperature is 450° C. or 500° C., the extrusion speed is 1 mm / s, and the extrusion ratio is 11, and a Mg-RE alloy rod with a diameter of 12 mm is prepared.

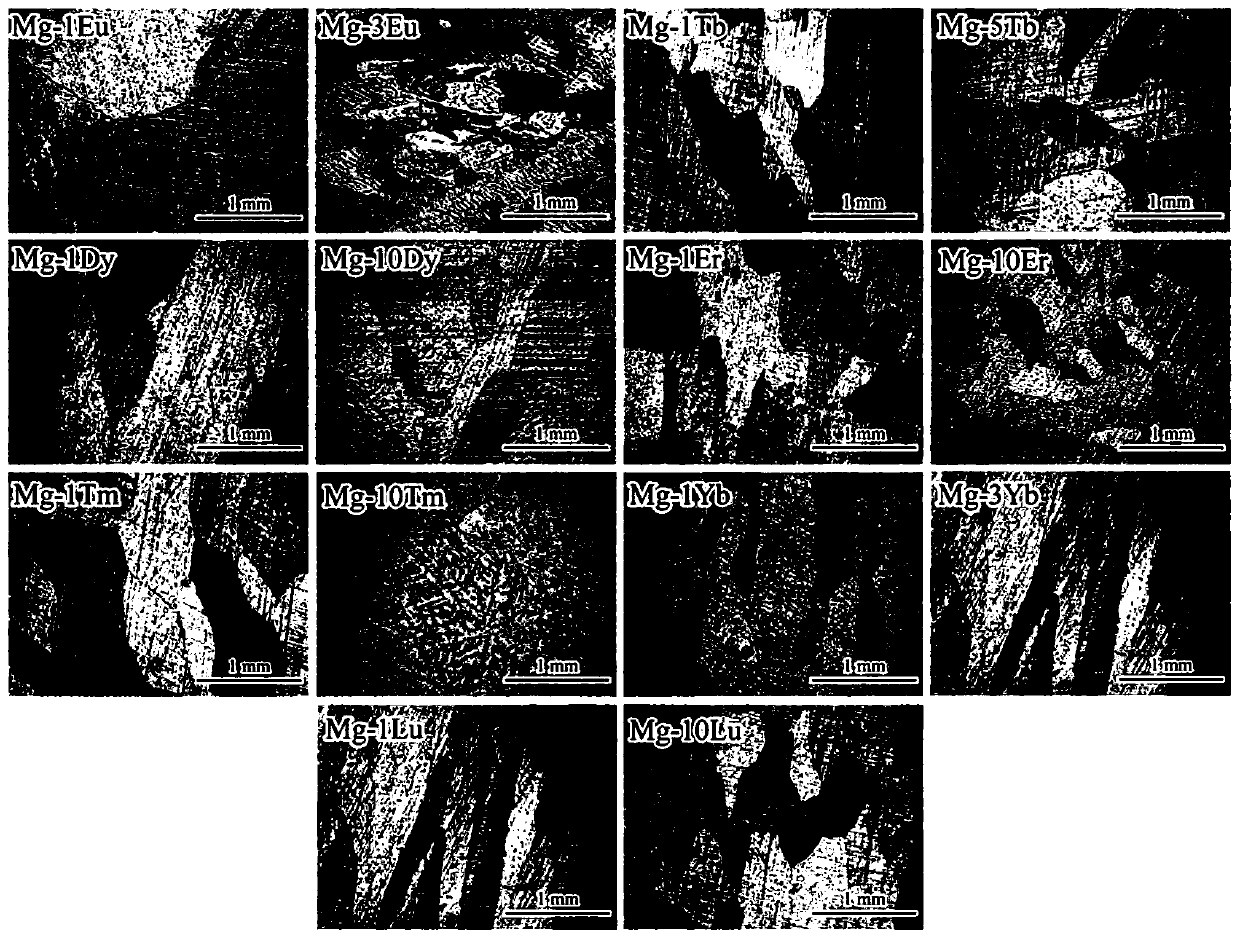

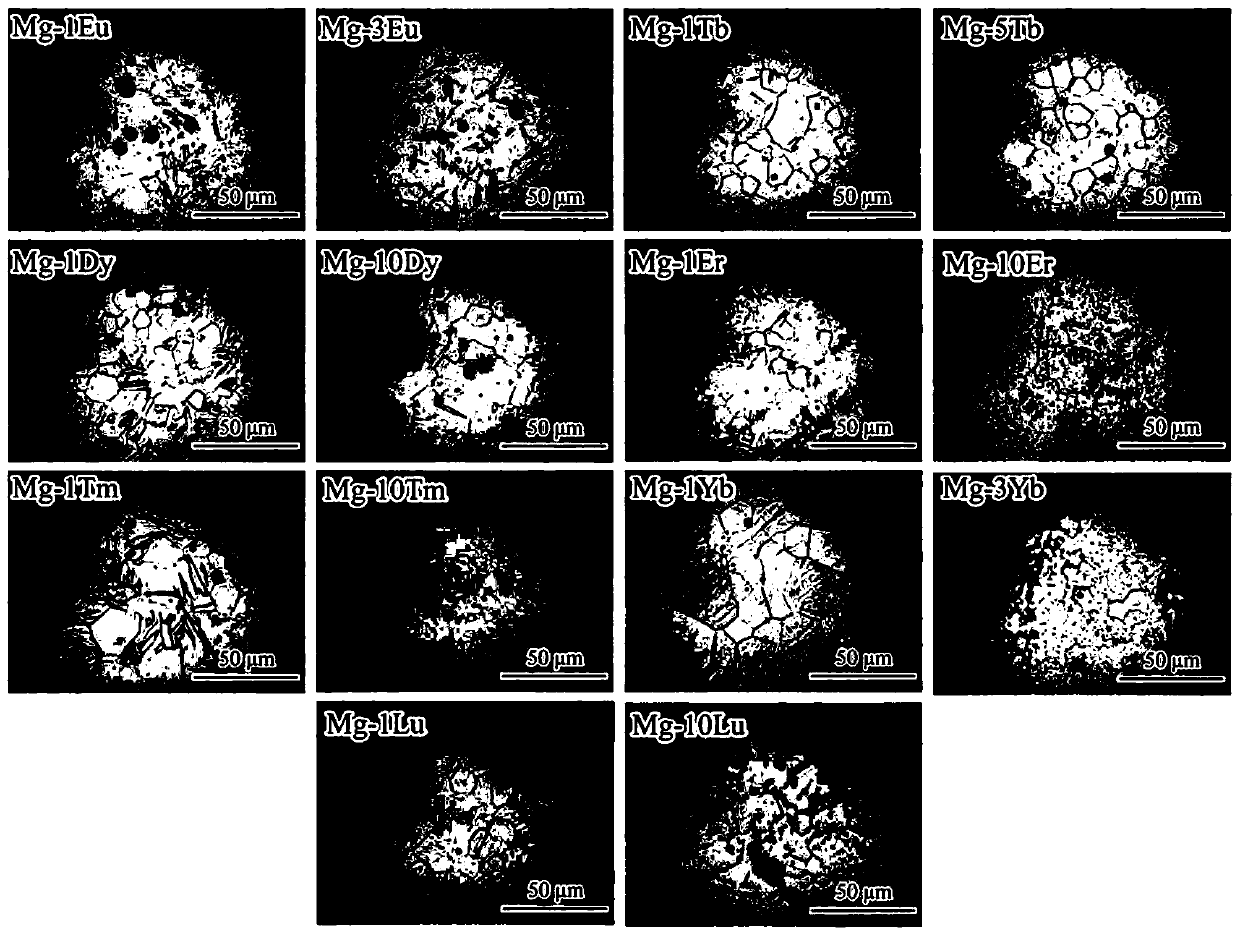

[0073] figure 2 The photo of the microstructure of the above sample shows that extrusion significantly improves the microstructure of the material, the original coarse grains are significantly thinner, and the coarser second phase is also broken, and its distribution is more uniform. The metallographic phase of a single-phase alloy or an extruded alloy containing a small amount of second phase presents a uni...

Embodiment 3

[0074] Embodiment 3, the corrosion performance test of Mg-RE series magnesium alloy

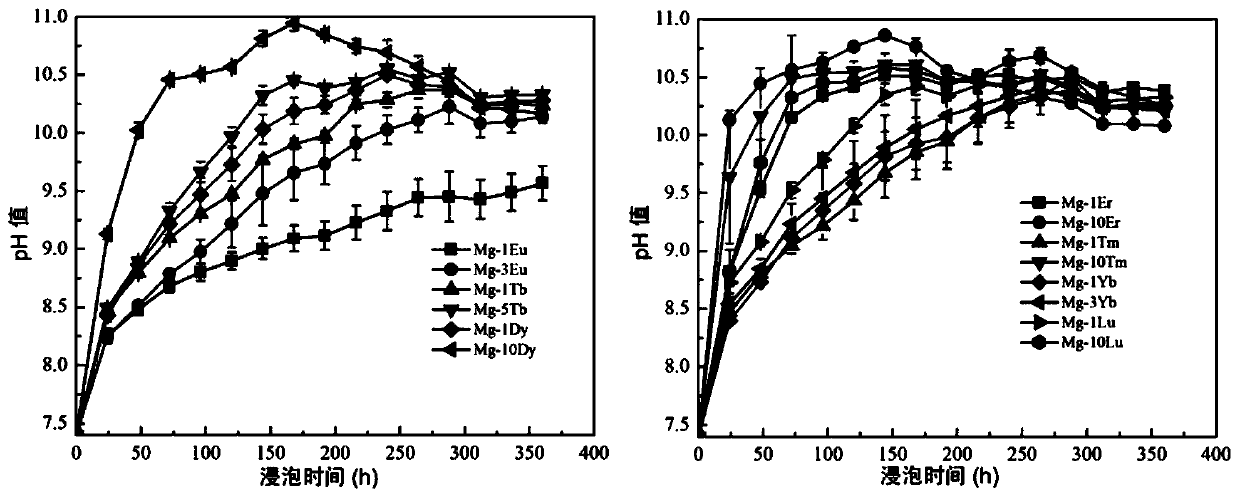

[0075] The extruded Mg-RE magnesium alloy prepared in Example 2 was cut into a block sample of Φ12mm×2mm, polished with 800#, 1200#, 2000# sandpaper in sequence, and ultrasonically cleaned with ethanol. Then in Hank’s simulated body fluid (NaCl 8.0g, CaCl 2 0.14g, KCl 0.4g, NaHCO 3 0.35g, glucose 1.0g, MgCl 2 6H 2 O 0.1g,Na 2 HPO 4 2H 2 O 0.06g, KH 2 PO 4 0.06g, MgSO 4 7H 2 (0.06g was dissolved in 1L deionized water) for immersion experiment, the ratio of the volume of the solution to the surface area of the sample was 20mL / cm 2 , record the pH change of the solution every day, such as image 3 shown.

[0076] Depend on image 3 It can be seen that in the early stage of immersion, the pH value increase rate of each combination of gold was significantly higher than that in the later stage. In general, the corrosion rate of Mg-1Eu is significantly lower than that of other M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com