Cabinet door chuck

A chuck and cabinet door technology, which is applied to building fastening devices, wing leaf fastening devices, buildings, etc., can solve the problems of inconvenient use and achieve the effect of simple and convenient operation and avoid automatic closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

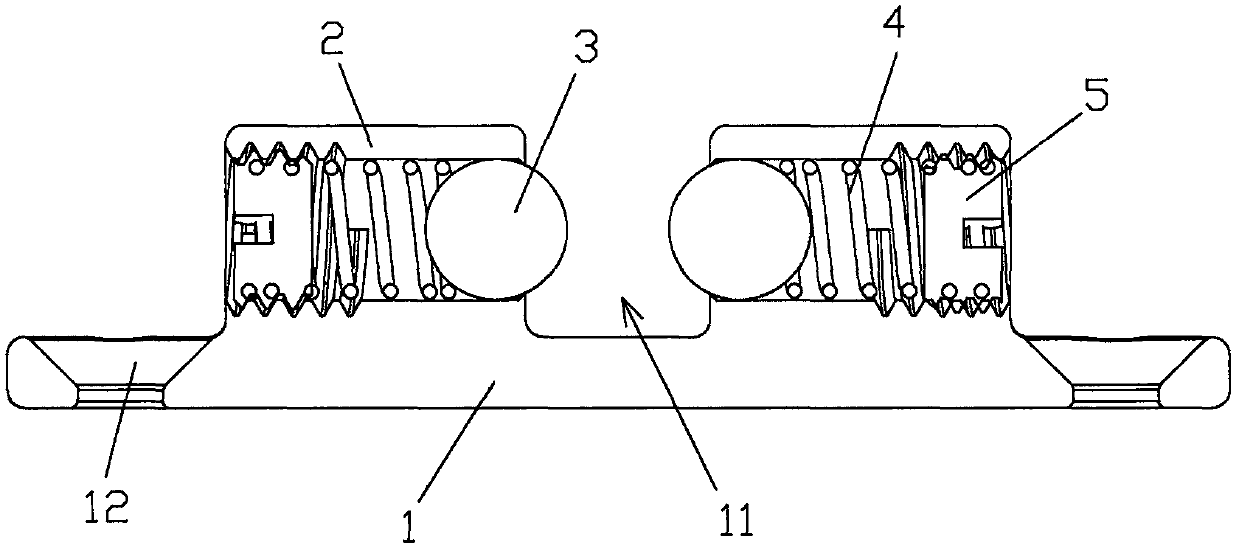

[0008] Such as figure 1 As shown, a cabinet door chuck includes a bottom plate 1, two sleeves 2 are arranged on the bottom plate 1, a spring 4, a steel ball 3 and a screw plug 5 are arranged in the sleeve 2, and the two ends of the spring 4 are respectively Against the steel ball 3 and the screw plug 5, one end of the steel ball 3 is exposed to the pipe sleeve 2 and is located in the gap 11 between the two pipe sleeves 2, and the two ends of the bottom plate 1 are provided with cones for installing countersunk screws. Shaped hole 12.

[0009] The protruding head on the cabinet door can be snapped into the gap 11 between the two steel balls 3, and the two steel balls 3 can position the protruding head to avoid automatic closing of the cabinet door, and the operation is simple and convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com