An edge distribution plasma cracking activation refueling device and method

A technology of plasma and edge distribution, applied in the direction of fuel heating of jet propulsion devices, rocket engine devices, turbine/propulsion devices, etc., can solve problems such as difficult to realize, high detonation energy, etc., to reduce detonation energy and improve detonation Frequency, the effect of shortening the detonation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

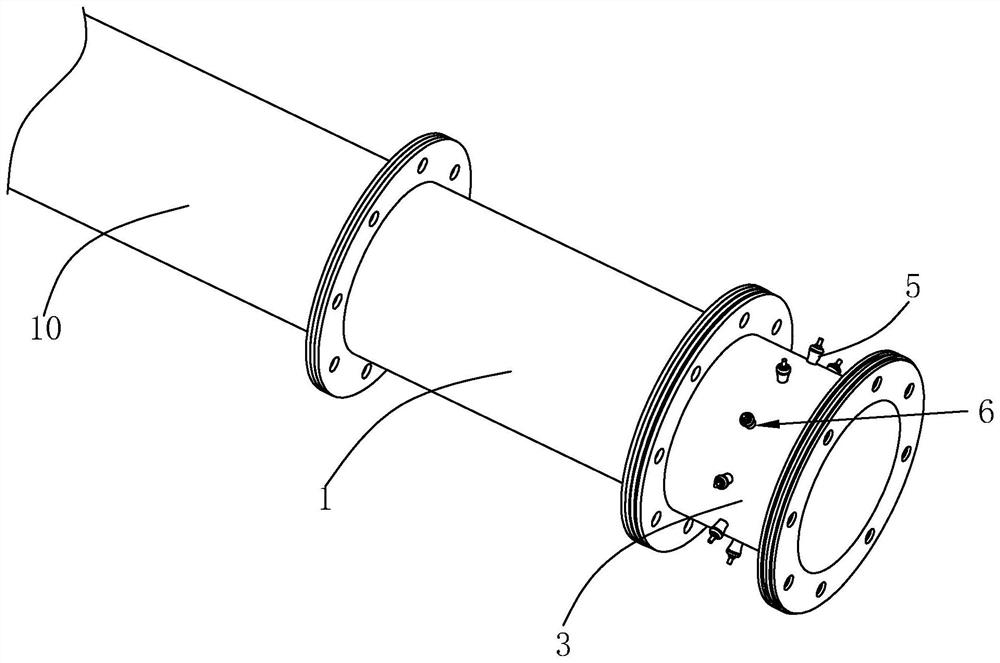

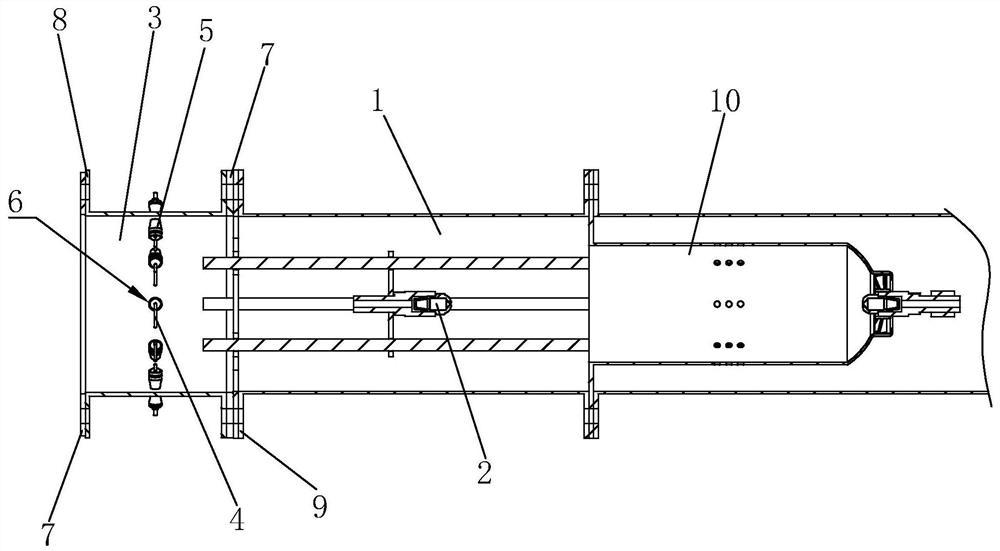

[0038] Such as figure 1 , 2 As shown, a kind of edge distribution plasma activated refueling device comprises a pre-combustion cracking chamber 1 with openings at both ends and a plasma control chamber 3 connected to one end of the pre-combustion cracking chamber 1, and a pre-combustion cracking chamber 1 is provided with The fuel injection nozzle 2 is provided with a discharge structure in the plasma control chamber 3, wherein the fuel injection nozzle 2 communicates with the oil supply device.

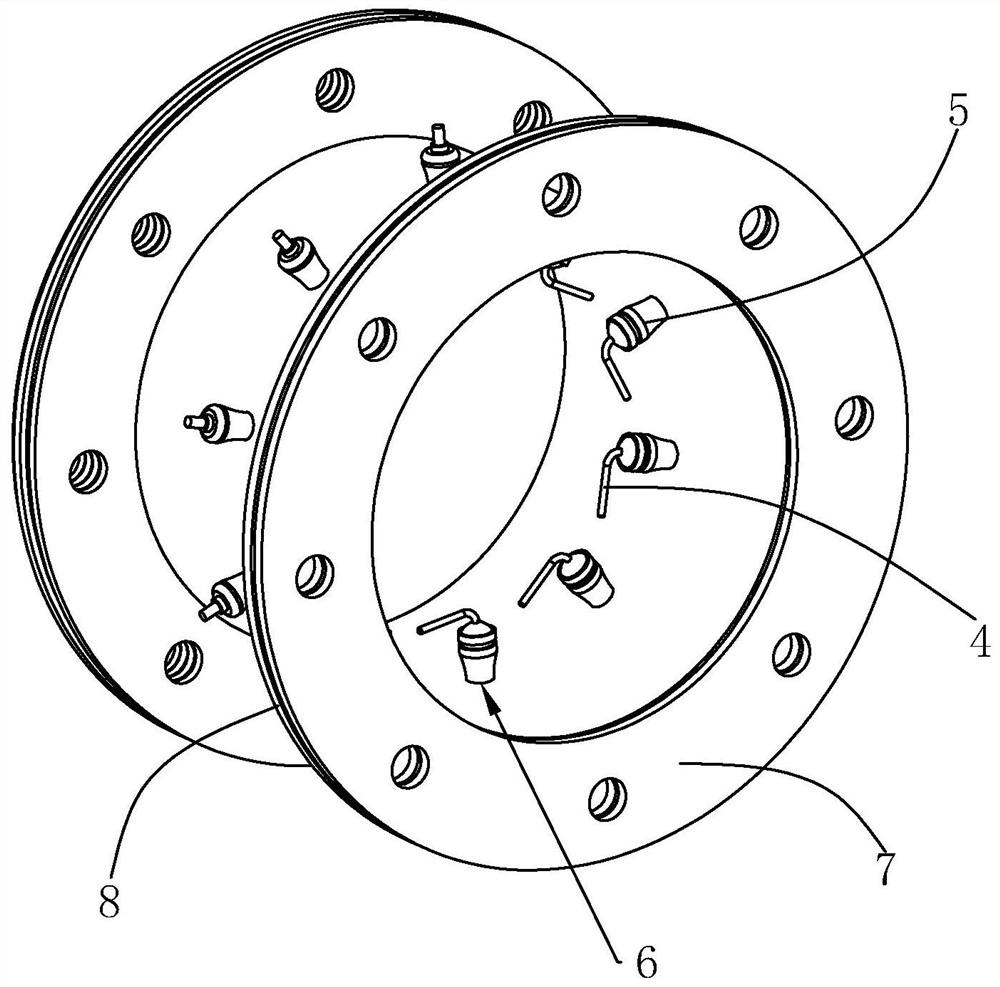

[0039] The shape of the plasma control chamber 3 is a hollow cylinder with openings at both ends. First connecting flanges 8 are arranged at both ends of the plasma control chamber 3. The first connecting flange 8 can facilitate the connection between the plasma control chamber 3 and the plasma control chamber 3. communicate with other components.

[0040] Such as figure 1 , 2 As shown, wherein, the pre-combustion cracking chamber 1 is cylindrical, and the two ends of the pre-com...

Embodiment 2

[0052] A cracking method, characterized in that: comprising the following steps:

[0053] Step 1: create a high temperature environment in the pre-combustion cracking chamber 1;

[0054] Step 2: After waiting for the temperature in the pre-combustion cracking chamber 1 to rise, fuel is injected into the pre-combustion cracking chamber 1, and the fuel is pyrolyzed;

[0055] Step 3: The pyrolyzed fuel is passed into the plasma control chamber, and the plasma formed by the discharge at the circumferential inner wall will activate the pyrolyzed fuel, thereby regulating the distribution of the pyrolyzed fuel components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com