A Wedge Surface Structure Using Thermal Jet to Control Oblique Detonation Wave Initiation

A hot jet and detonation wave technology, applied in the direction of machines/engines, jet propulsion devices, etc., can solve the problems of increasing engine size, increasing engine weight, increasing resistance, etc., and achieves small total pressure loss and optimized thrust performance , the effect of small resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below with reference to the accompanying drawings.

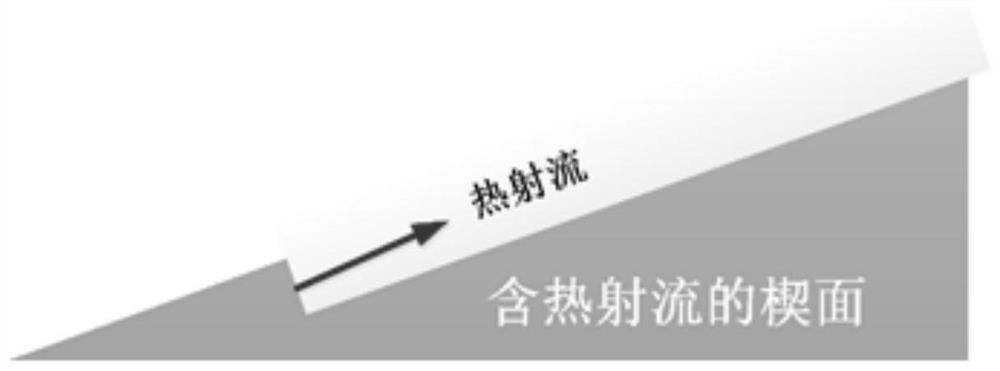

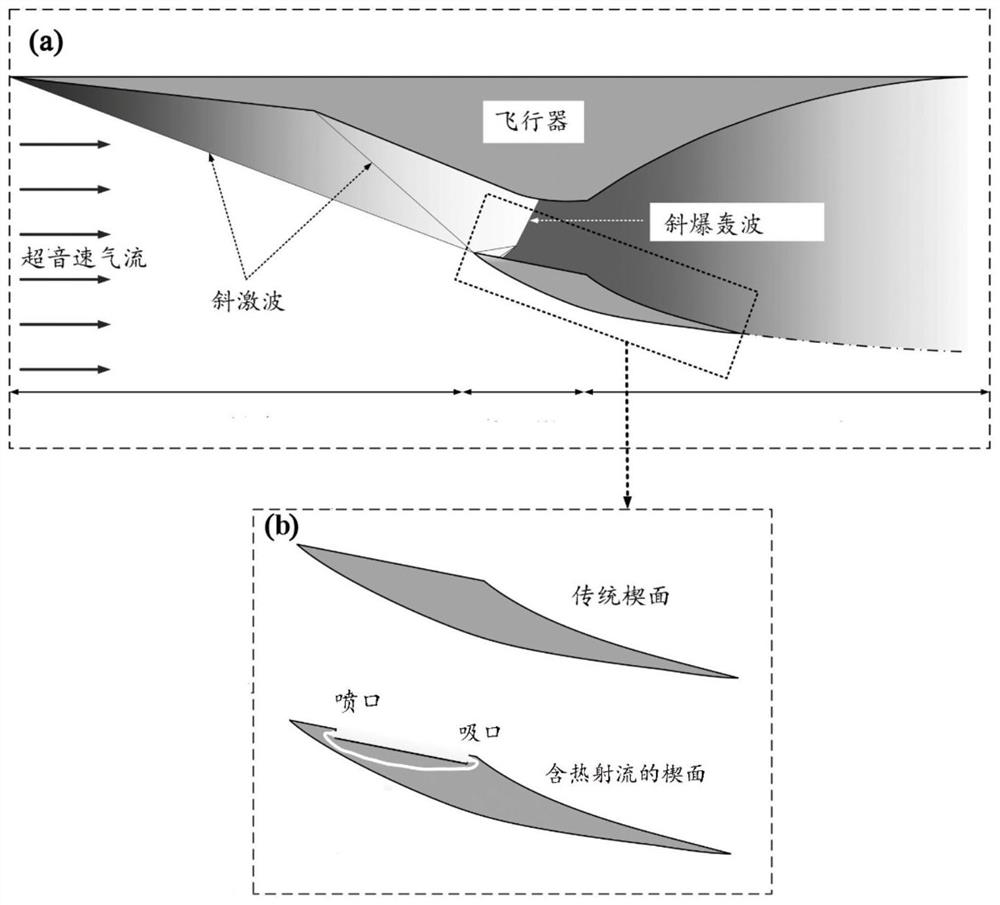

[0017] like figure 2 and 3 As shown, the present invention provides a wedge structure that utilizes a thermal jets to explodes the blast wave, which is an object of which is stabilized in the optimal position by the thermal jet at a smaller wedge angle. Make minimal resistance, the total pressure loss is minimized, so that the thrust performance is optimized.

[0018] The present application adds a spout on the basis of a flat wedge, introducing the engine detonation product and ejects from the spout, and the sprayed thermal jet forms a gas wedge, the gas wedge induces a new inclined wave, pass through The temperature rise of the oblique excitement realizes the explosion of oblique bangs.

[0019] The intensity of the thermal jet can be adjusted according to the actual flight conditions, thereby controlling the explosion of the oblique blast wave.

[0020] The jet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com