Support and hanger quantifying, mounting, detecting and regulating tool and method using same to perform support and hanger load measurement

A support and hanger and adjustment technology, applied in measuring devices, pipeline supports, force/torque/work measuring instruments, etc., can solve problems such as low efficiency, damage to support and hanger related components, support and hanger breakage, etc. Efficiency, Simplified Installation, Accurately Quantified Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

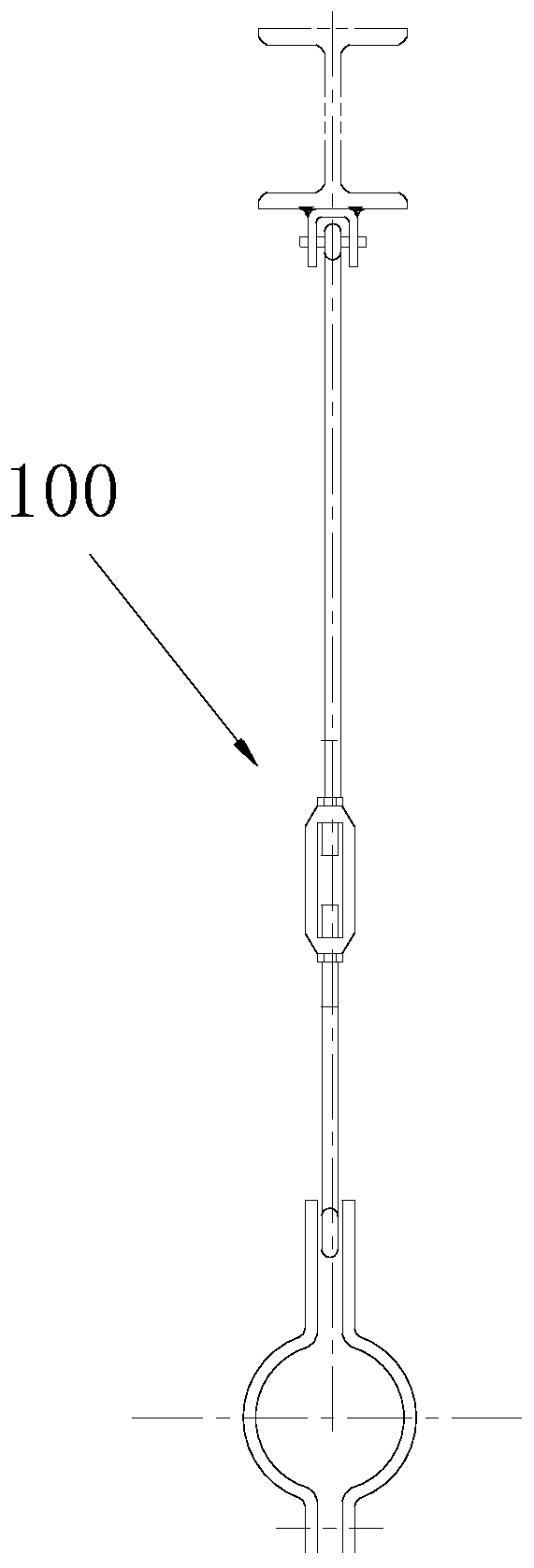

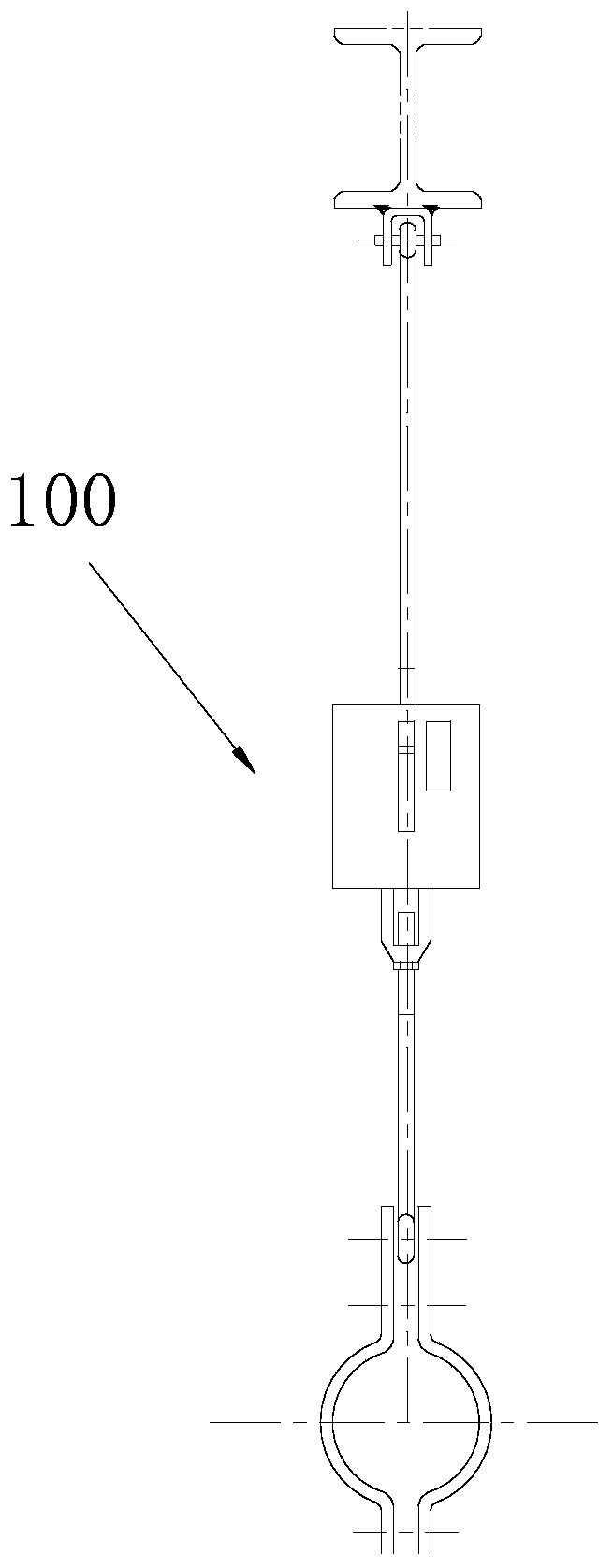

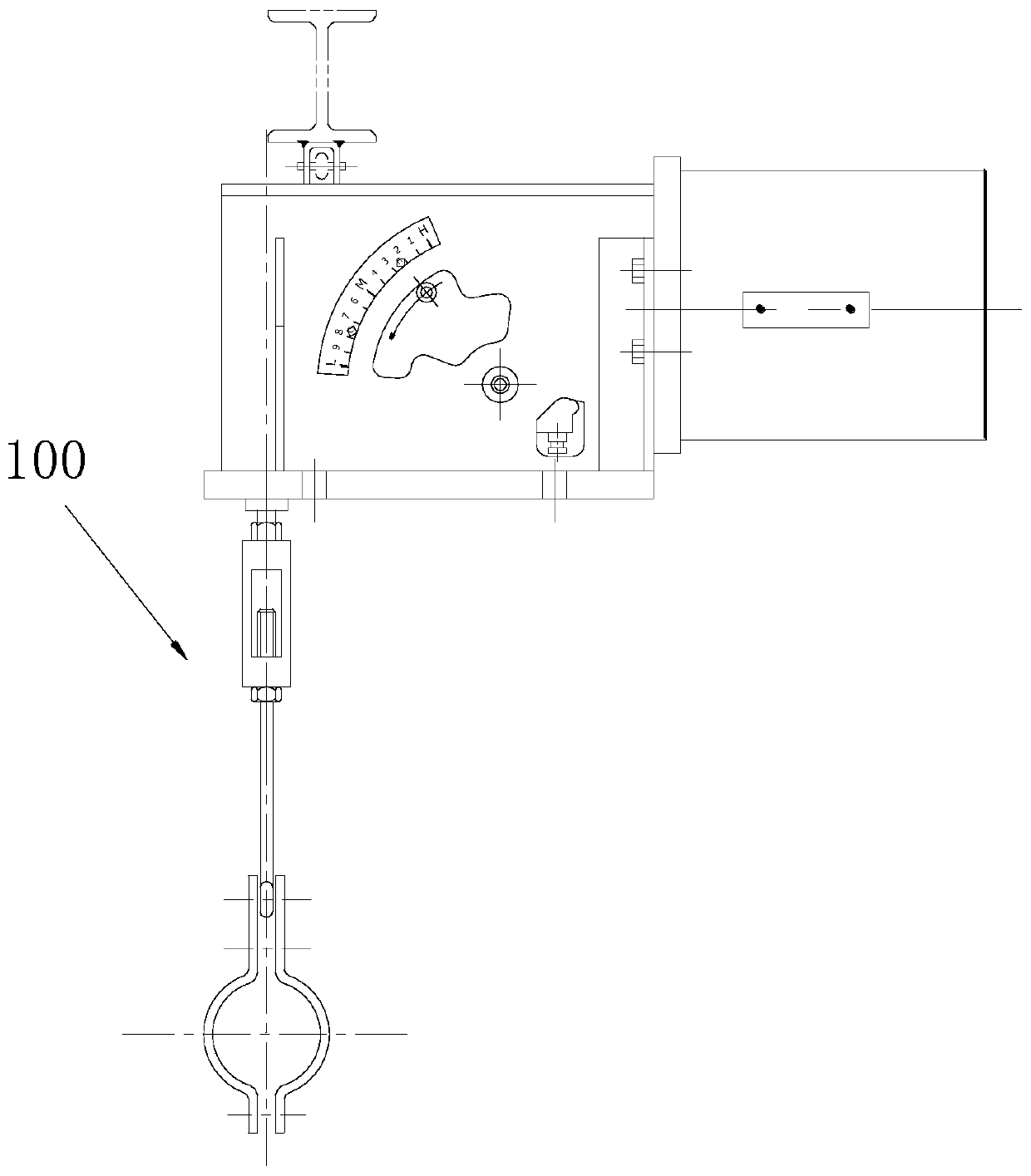

[0038] Such as Figure 4 to Figure 9 As shown, a support and hanger quantitative installation testing and adjustment tool, wherein the support and hanger 100 includes a suspender 1 and a turnbuckle 2 provided on the suspender 1 , and the turnbuckle 2 is used to adjust the length of the suspender 1 . The adjustment tool 200 includes a first support assembly 3 arranged on the suspension rod 1 and located below the turnbuckle 2 and a second support assembly 4 located above the turnbuckle 2, and the first support assembly 3 and the second support assembly 4 are arranged between The force measuring assembly, the force measuring assembly at least includes a dowel bar 5 erected between the first support assembly 3 and the second support assembly 4 and extending parallel to the suspension rod 1, a strain sensor 6 attached to the dowel bar 5, and A loading and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com