Workpiece transfer trolley

A transfer vehicle and workpiece technology, which is applied in trolleys, motor vehicles, multi-axis trolleys, etc., can solve the problems of difficult control of the transfer direction and limited applicable places, etc., and achieve manual operation, wide application occasions, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

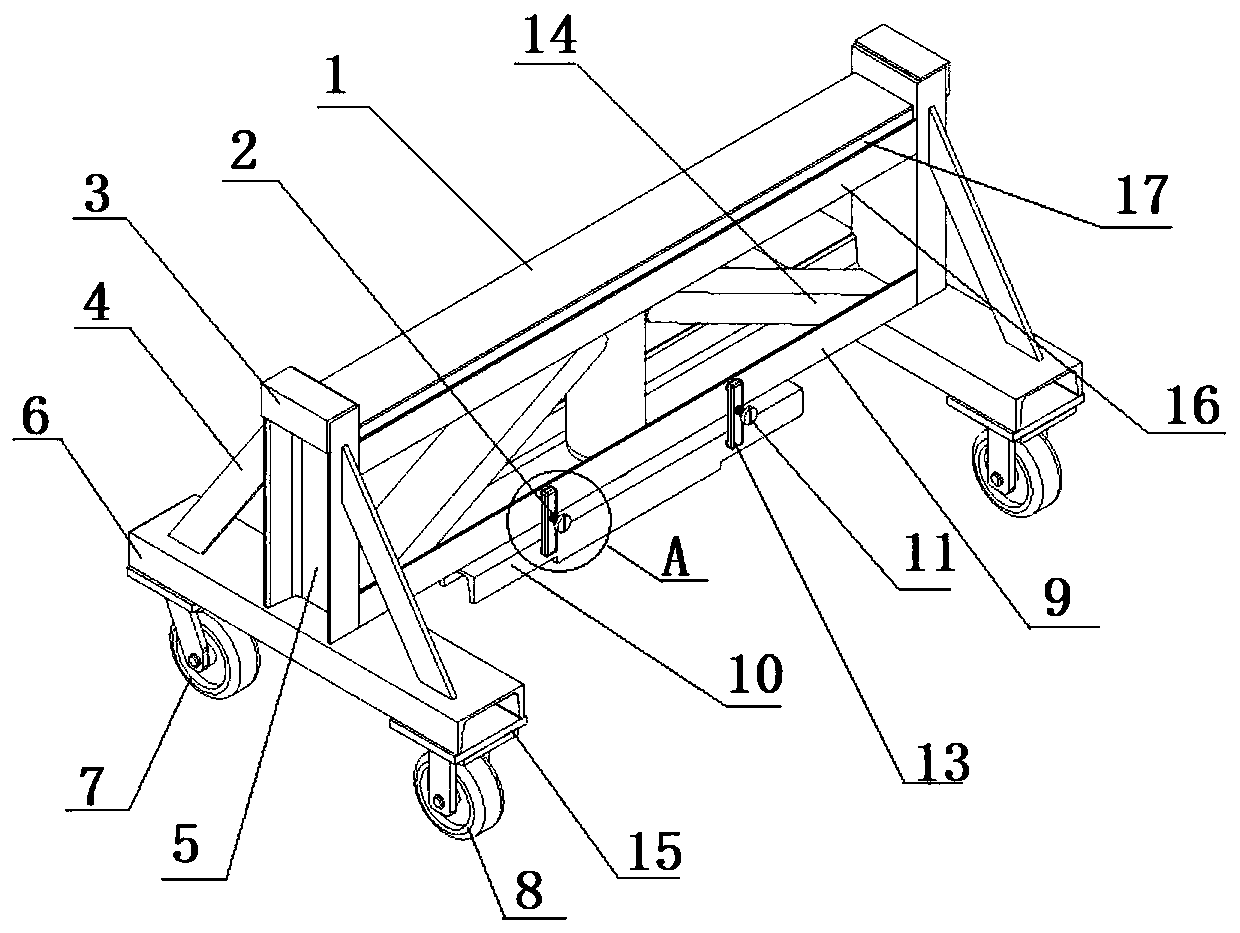

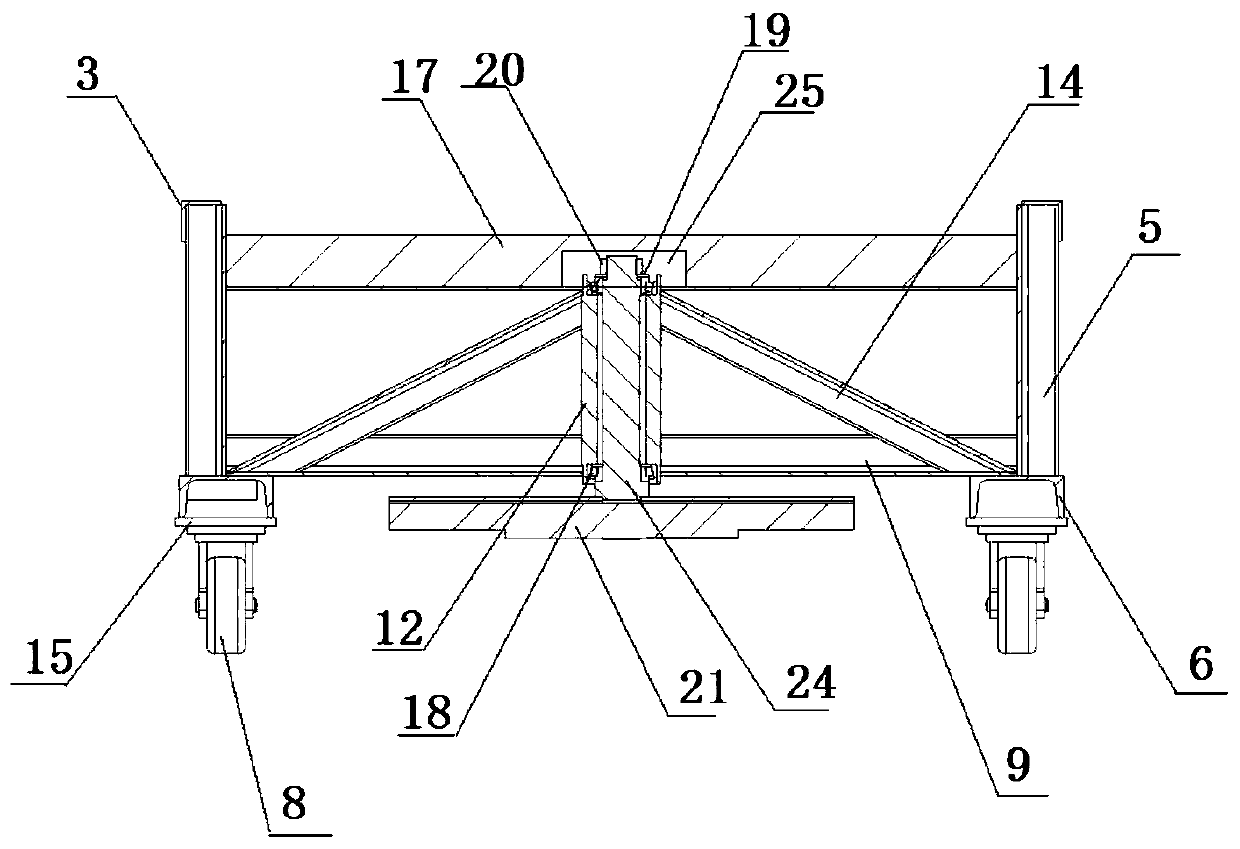

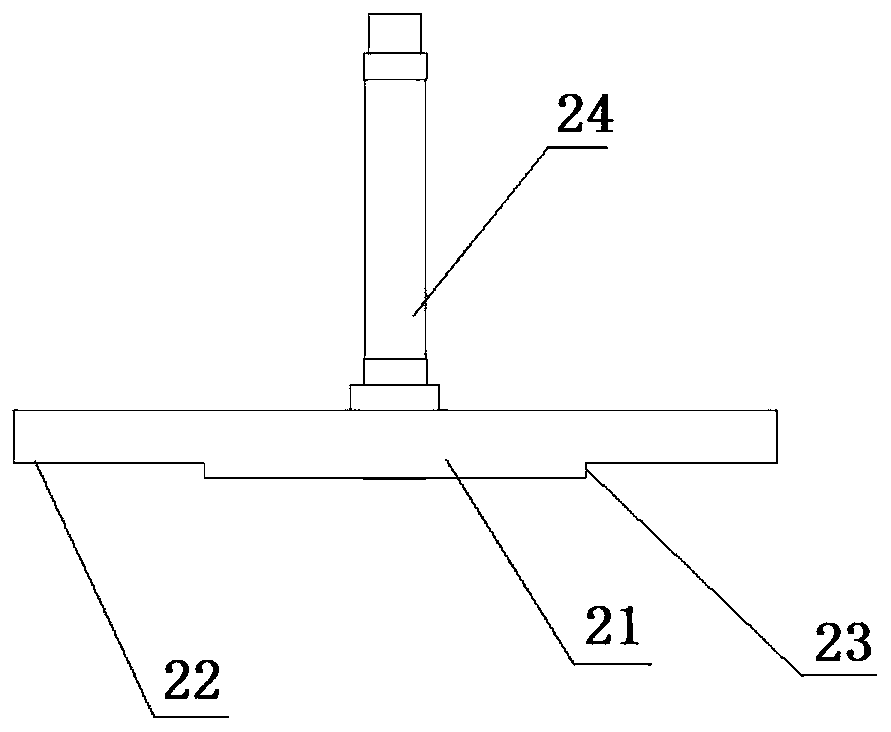

[0041] Such as figure 1 As shown, the workpiece transfer vehicle includes a vehicle frame, and the vehicle frame includes laterally arranged support frames on both sides, and two intermediate connection frames corresponding to the two ends that are welded and fixedly connected to the two support frames. There are walking wheels, and a supporting positioning groove for supporting and placing workpieces is provided on the top of the intermediate connecting frame body; moreover, a supporting bracket is rotatably assembled on the bottom of the intermediate connecting frame body through a bearing structure. When in use, the workpiece transfer vehicle can move and turn with the help of the walking wheels, and the fork arm of the forklift can also be used to support the support bracket to lift the workpiece transfer vehicle, so that the walking wheels are off the ground, and the workpiece transfer vehicle is pulled by the forklift to move to realize workpiece The movement and steerin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com