Power gear shifting transmission and vehicle

A power shift and transmission technology, applied in the field of power shift transmissions and vehicles, can solve the problems of large volume and high cost of power shift transmissions, achieve simple structure, reduce occupied space and production cost, and meet shifting requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

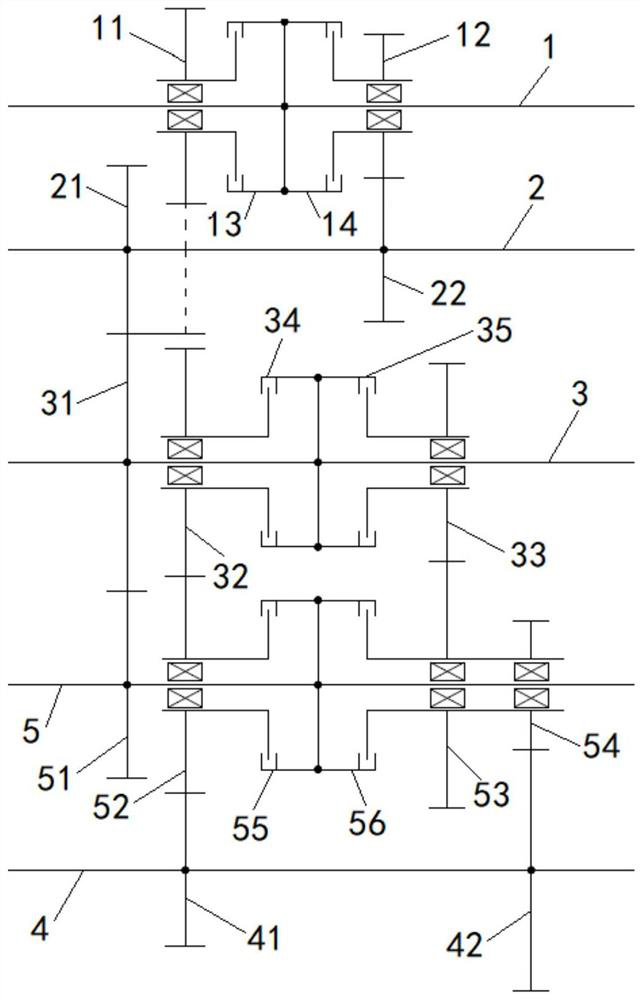

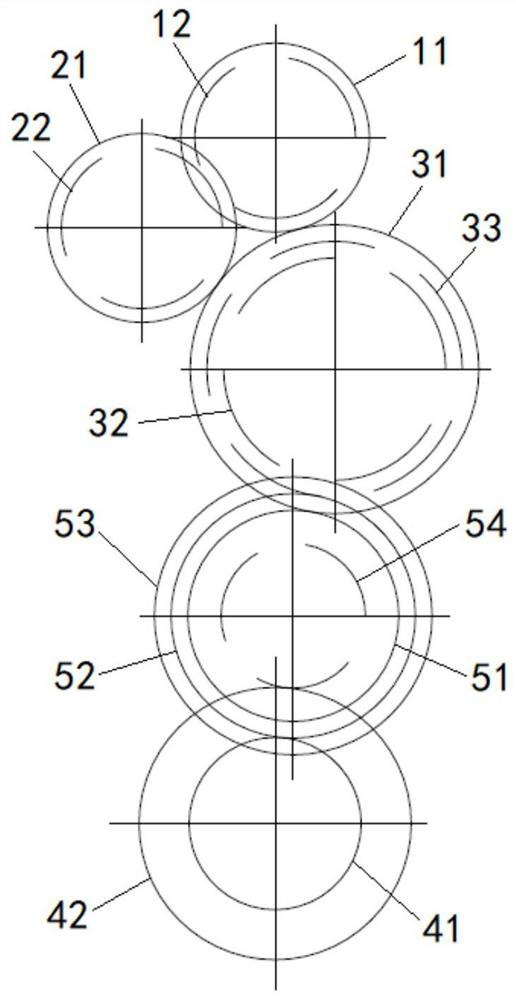

[0063] The difference between this embodiment and Embodiment 1 is that the number of teeth of the first fixed gear 21 is smaller than the number of teeth of the second fixed gear 22, and the first movable gear 11, the first fixed gear 21 and the third fixed gear 31 can be arranged on In the same plane, reduce the axial width of the transmission.

[0064] It should be noted that the first movable gear 11 and the first fixed gear 21 can also continue to be axially misaligned, but the axial width of the transmission will be correspondingly increased.

Embodiment 3

[0066] In this embodiment, on the basis of Embodiment 1, a fifth shaft parallel to the third shaft 4 is added, and the fifth shaft is provided with a seventh fixed gear fixed thereto; the seventh fixed gear and the fifth fixed gear 41 Or the sixth fixed gear 42 meshes.

[0067] In other embodiments, an eighth fixed gear fixed relative to the third shaft 4 and meshed with the seventh fixed gear can also be provided on the third shaft 4 .

[0068] In this embodiment, the fifth shaft is used as the output shaft, and the third shaft 4 is used as the shaft for power transmission between the input shaft 1 and the fifth shaft. Only one seventh fixed gear is arranged on the fifth shaft, and the The bearing force is relatively balanced. On the premise that the installation space meets the requirements, the power shift transmission provided by this embodiment can be used according to the requirements of the transmission ratio.

Embodiment 4

[0070]This embodiment provides a vehicle, including the power shift transmission defined in Embodiment 1 and an emergency shaft, wherein the third shaft 4 is parallel to the emergency shaft, and an emergency gear is arranged on the emergency shaft, and the emergency gear and the emergency gear are arranged on the third shaft. 4 and one of the gears that can be fixed relative to the third shaft 4 meshes, specifically, the emergency gear meshes with the fifth fixed gear 41 or the sixth fixed gear 42; the emergency gear is fixed relative to the emergency shaft, and the emergency shaft can selectively Connect or disconnect from the vehicle's steering system. As for how the emergency shaft is selectively connected or disconnected from the steering system, a clutch or other methods in the prior art can be used, which will not be described in detail here.

[0071] When the vehicle using the above-mentioned power shift transmission breaks down and cannot walk, it is usually dragged by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com