Steel mesh template and manufacturing method thereof

A manufacturing method and template technology, which are applied in the direction of assembling printed circuits with electrical components, can solve the problems affecting the utilization rate of steel sheets, the space occupied by mesh yarns, and the increase of production costs, so as to achieve high work efficiency, increase useful space, and improve The effect of usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

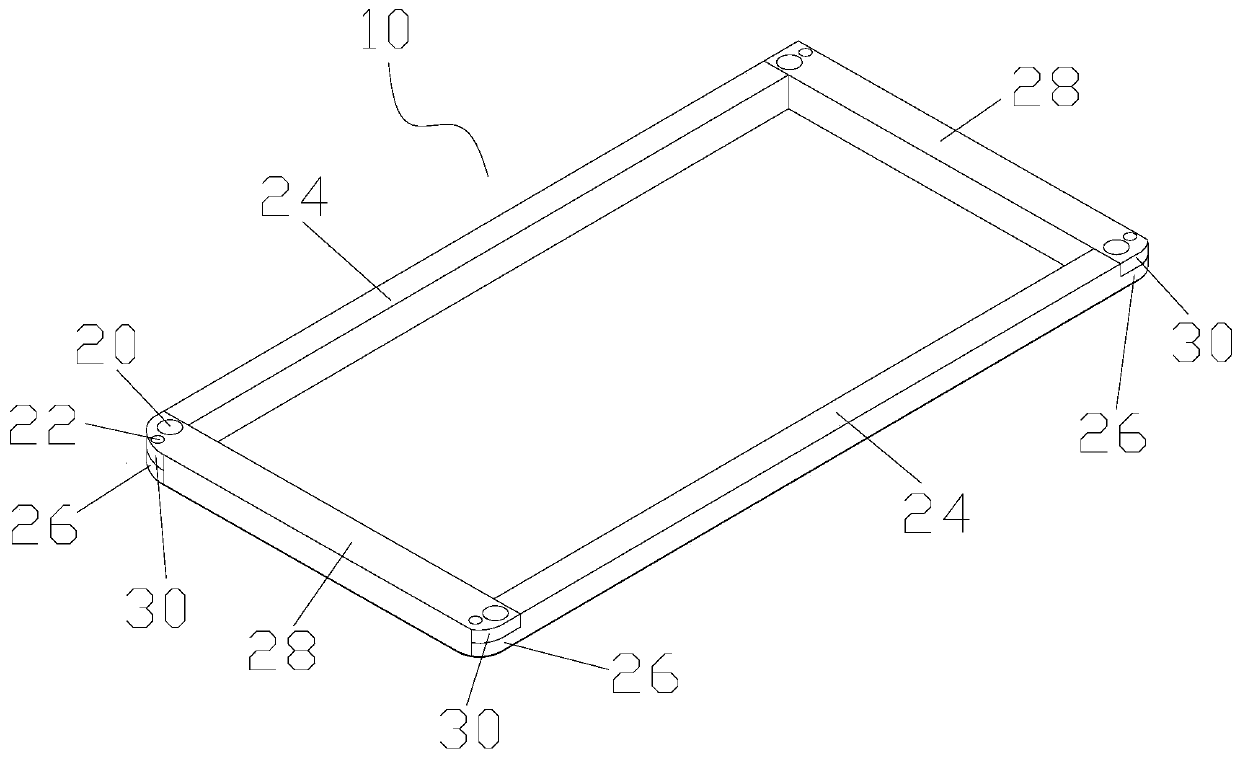

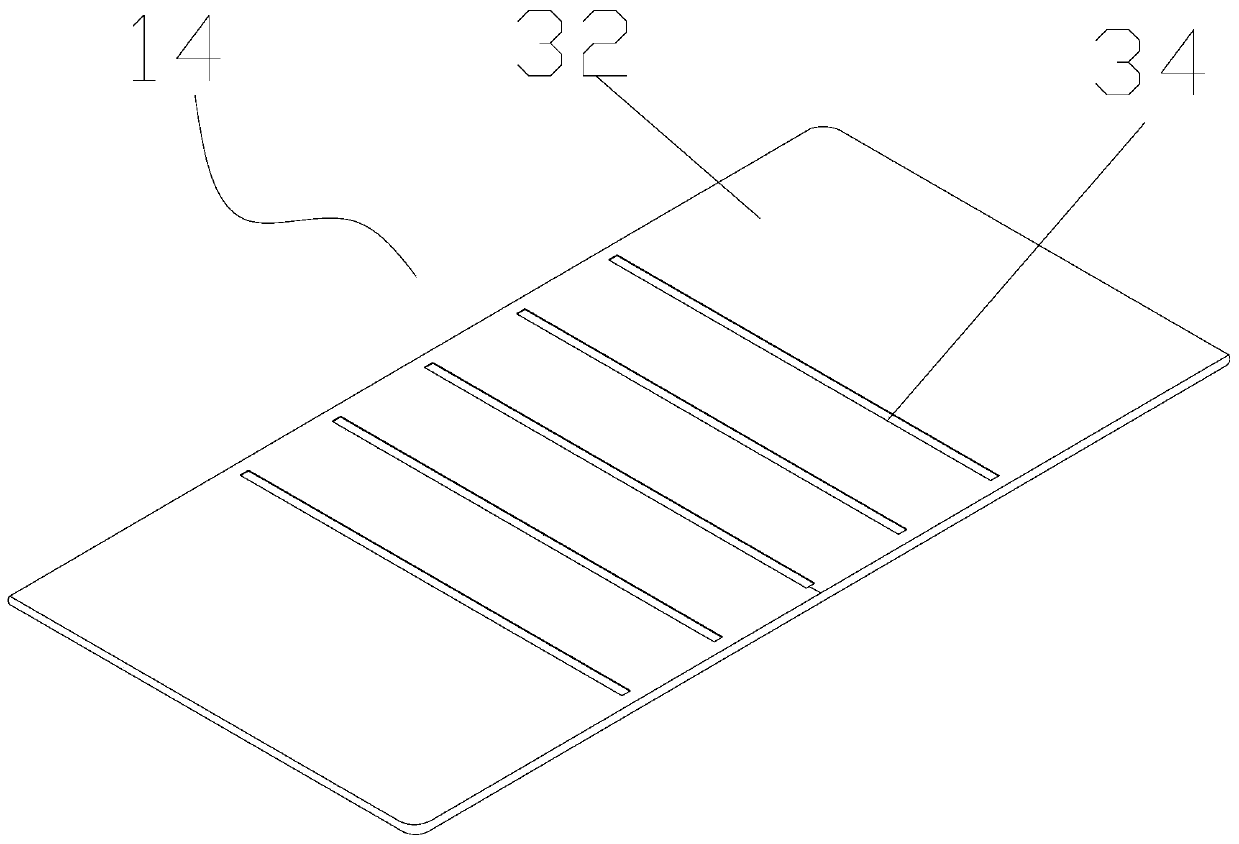

[0022] A steel mesh template includes an iron frame 10 and a stainless steel sheet 14, and the four sides of the stainless steel sheet 14 are respectively fixed on the four sides of the iron frame 10.

[0023] Such as figure 1 , figure 2 Shown, a kind of manufacture method of stencil formwork, comprises the following steps:

[0024] (1) Put the iron frame 10 into the clamping mechanism, and clamp the iron frame 10;

[0025] (2) Place the stainless steel sheet 14 on the iron frame 10, and connect the stainless steel sheet 14 to the iron frame 10;

[0026] (3) The clamping mechanism loosens the iron frame 10, the stainless steel sheet 14 ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clamping force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com