Electro-hydraulic anchoring device

An anchoring device, electro-hydraulic technology, applied in wellbore/well components, earthwork drilling and production, etc., to achieve stable and reliable anchoring process and large anchoring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

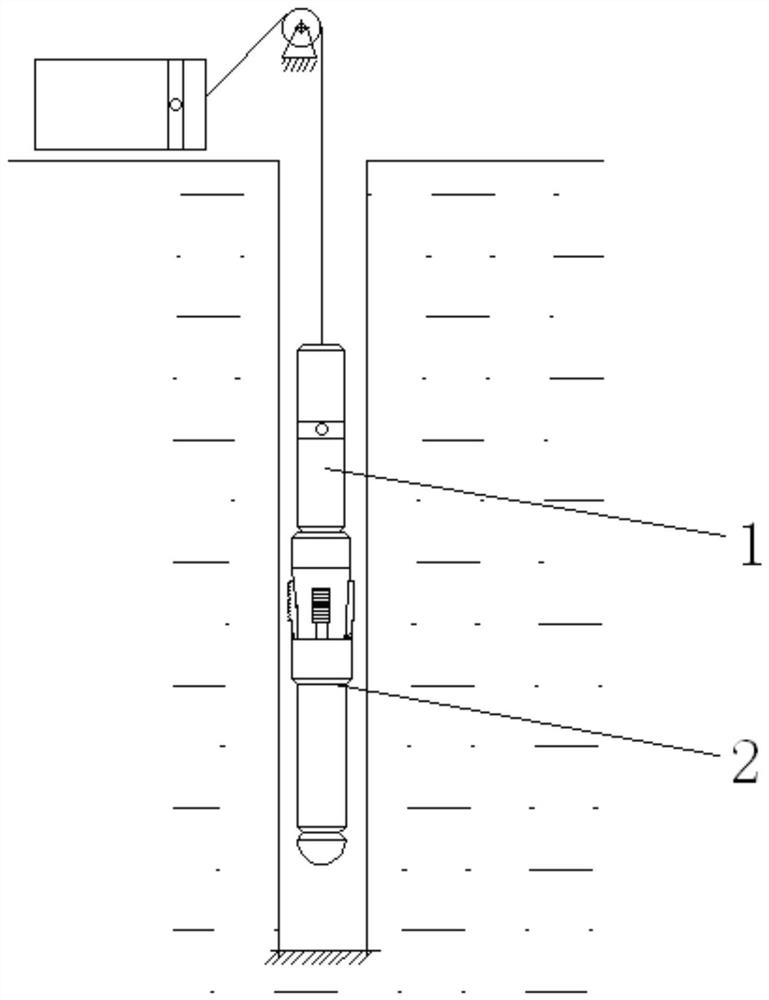

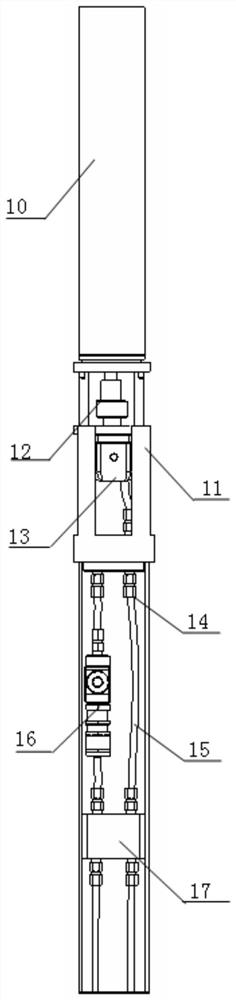

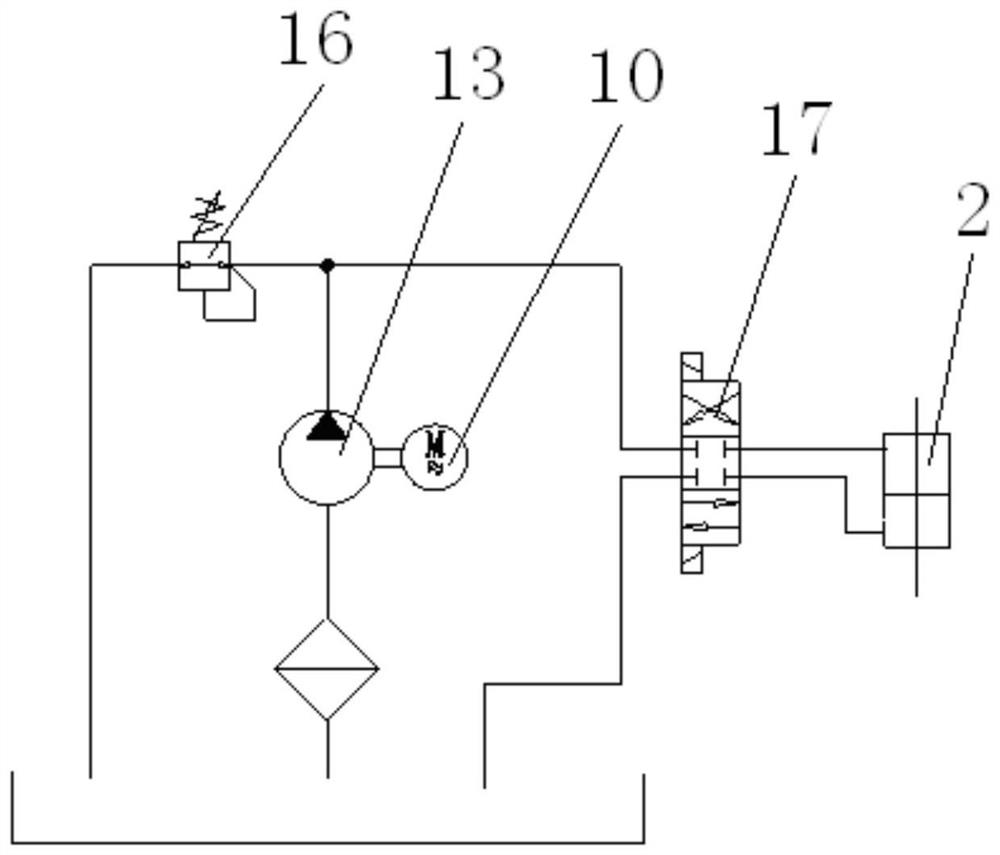

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, an electro-hydraulic anchoring device includes a power unit 1 and a mechanical unit 2. The power unit 1 includes a motor 10, a hydraulic pump 13 and an electromagnetic reversing valve 17. The output shaft of the motor 10 is connected to the The input shafts of the hydraulic pump 13 are connected, and different shafts are allowed; the hydraulic pump 13 is connected to the electromagnetic reversing valve 17 through the hydraulic pipe 15, and the overflow valve 16 is installed between the hydraulic pump 13 and the electromagnetic reversing valve 17 The overflow valve 16 is a constant pressure protection element of the hydraulic system, ensuring that the system oil pressure can be stabilized at a set value. The electromagnetic reversing valve 17 has three functions of "X", "II" and "O". The electromagnetic reversing valve 17 can realize three different oil pressure output states.

[0022] The mechanical unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com