Hydraulic expansion self-locking sealed flushable well packer

A well-flushing packer, closed technology, used in sealing/packing, wellbore/well components, earth-moving drilling, etc. The water injection process has developed to high temperature, high pressure and high efficiency, so as to achieve the effect of reliable sealing and reliable unsealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

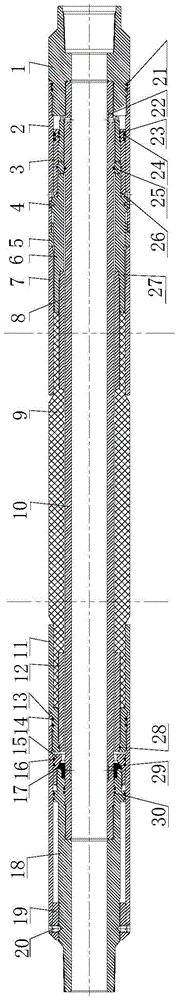

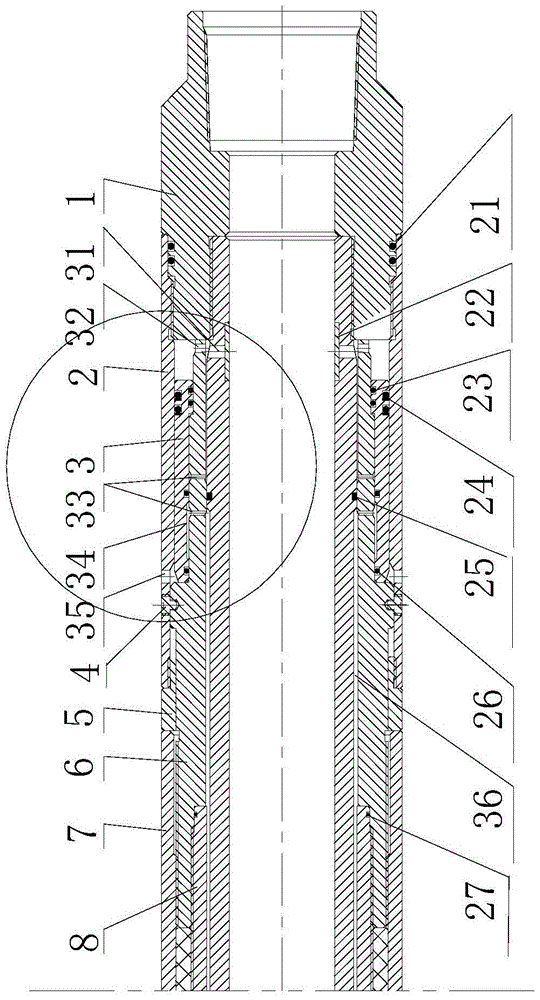

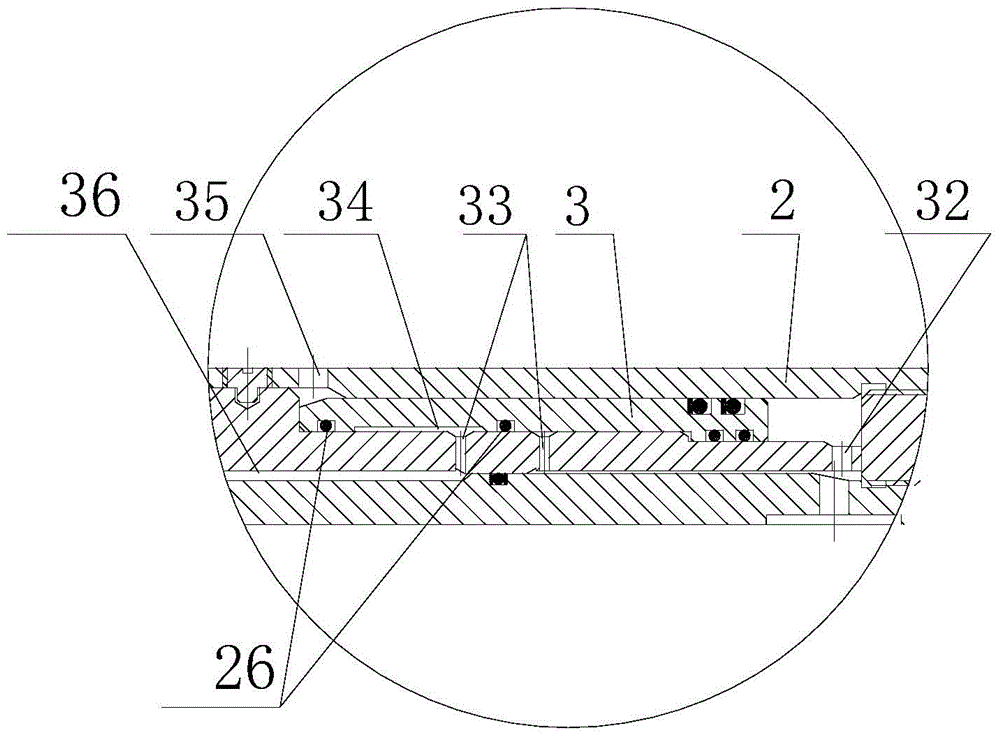

[0027] A hydraulic expansion self-locking hermetic washable well packer, comprising a center pipe 10, a rubber barrel 9, a vulcanized upper joint 8, a vulcanized lower joint 12, an upper joint 1, a lower joint 18, an upper outer short barrel 2, a lower outer Short tube 13, rubber sleeve upper pressure sleeve 7, rubber sleeve lower pressure sleeve 11, the rubber sleeve is set in the middle outside the central tube, the two ends of the rubber sleeve are formed with vulcanized upper joints and vulcanized lower joints, and the two ends of the central tube are fixed by threads. Install the upper joint and the lower joint, install the upper outer short tube and the upper pressure sleeve of the rubber tube between the upper joint and the vu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com