Detection fixture with power supply protection device

A technology for detecting fixtures and power supply protection, applied in overload protection devices and other directions, can solve problems such as electric shock, inability to effectively reduce electric shock, etc., and achieve the effect of reducing the risk of electric shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In the following, the technical means adopted by the present invention to achieve the intended purpose of the invention will be further described in conjunction with the accompanying drawings and preferred embodiments of the present invention.

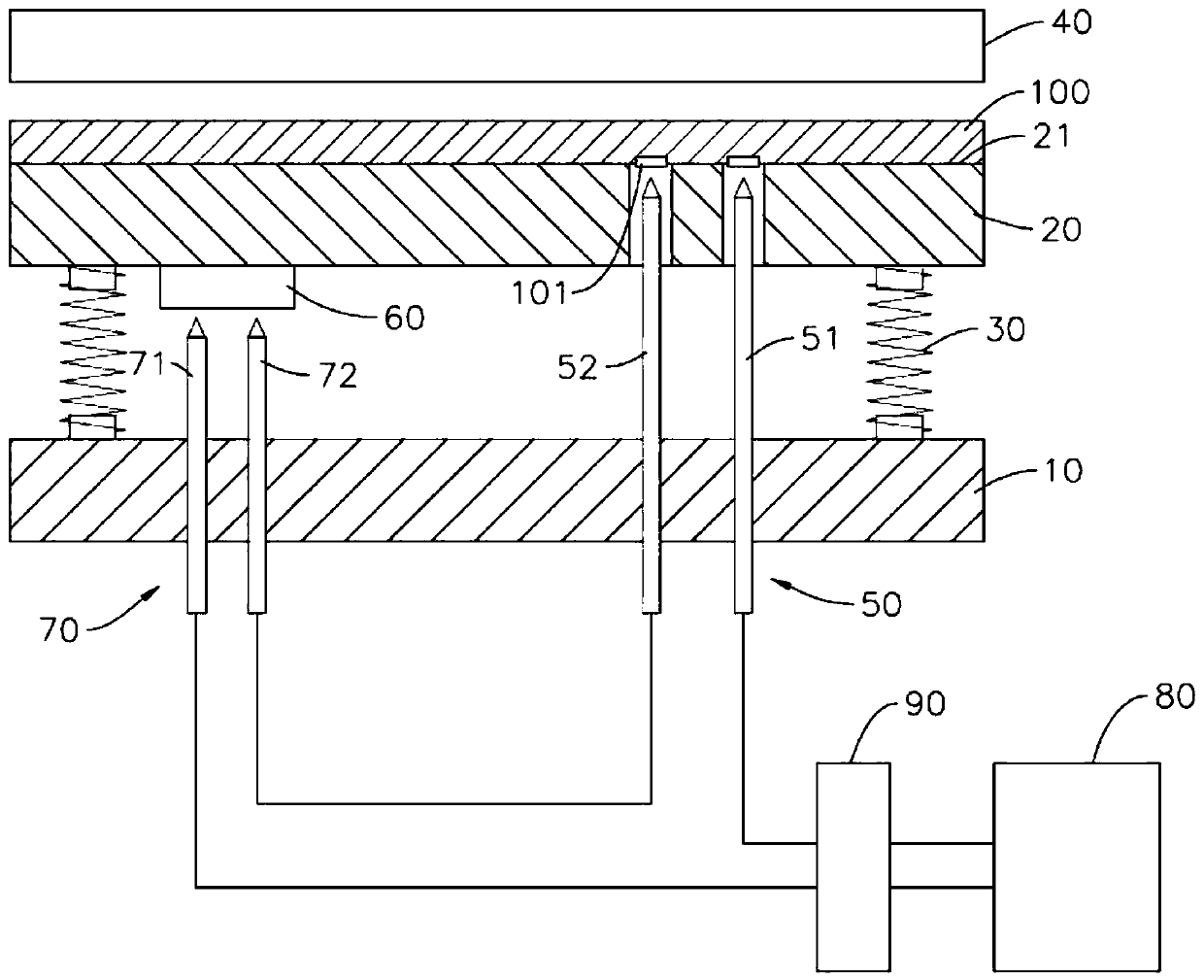

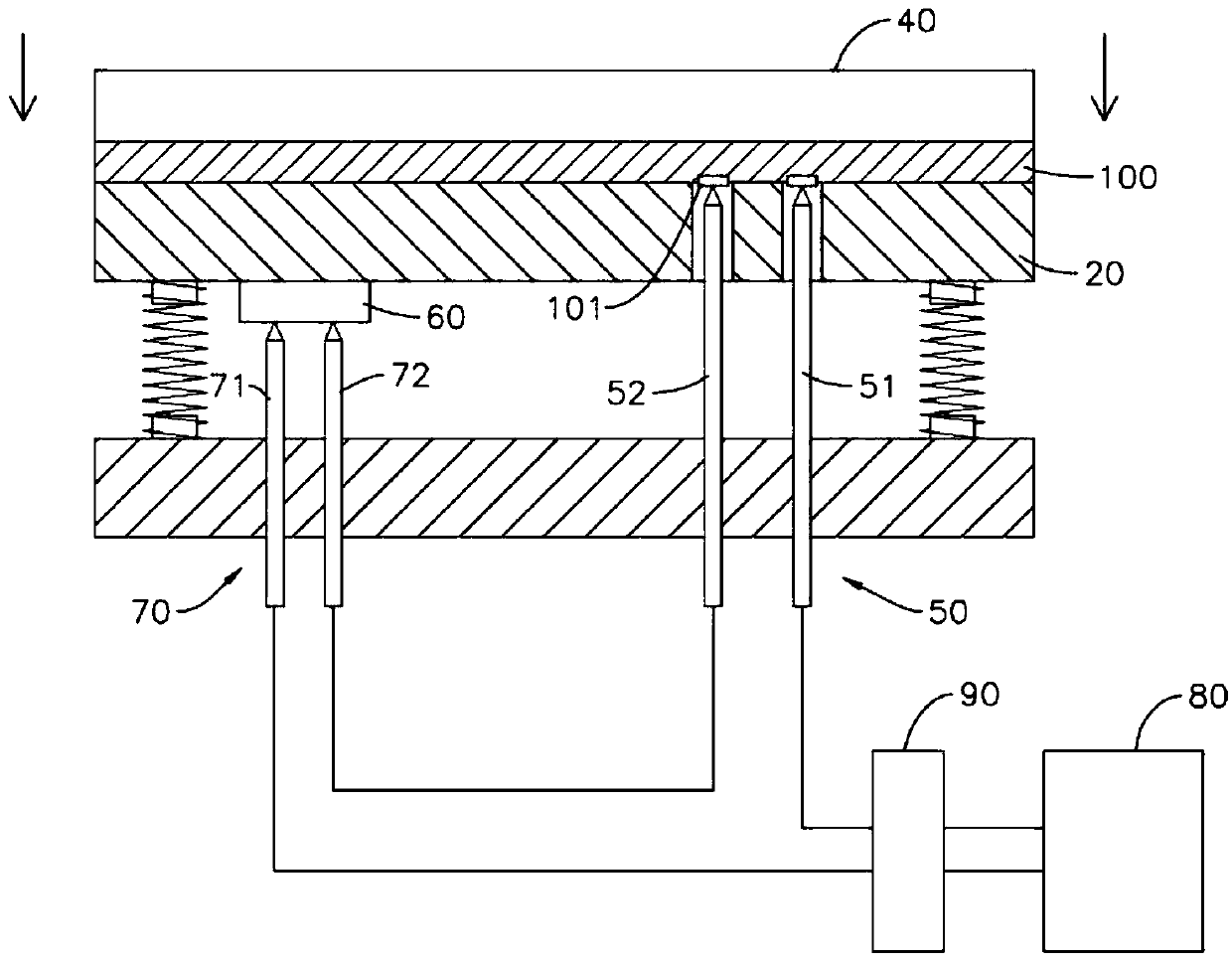

[0019] see figure 1 As shown, the detection jig with power supply protection device of the present invention includes a bottom plate 10, a carrier plate 20, at least one elastic element 30, a pressure plate 40, a first thimble group 50, a conductive sheet 60, a second thimble Group 70, a power supply 80 and a hand-cut switch 90; the press-fit detection fixture of the present invention is used to detect a product to be tested 100, and the product to be tested 100 has two power supply points 101. In this embodiment, the product to be tested 100 is a circuit board, but not limited thereto.

[0020] The aforementioned carrier board 20 is spaced above the base plate 10 , and the top surface 21 of the carrier board 20 is used to carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com