Improved coaxial cable connector hot-line mounting technology

A technology of coaxial cable and installation process, applied in the direction of connecting/terminating cable equipment, etc., can solve problems such as loss, achieve the effect of speeding up the construction process, increasing work efficiency, and reducing resource input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] An improved coaxial cable joint live installation process, the process includes the following steps:

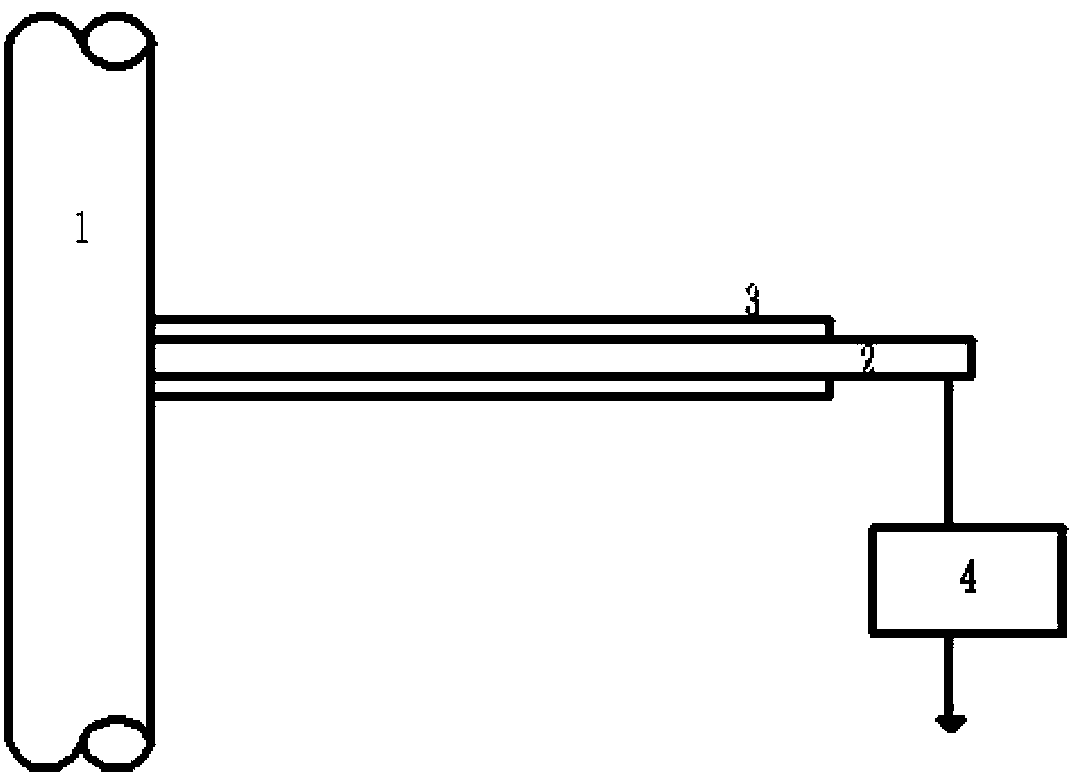

[0028] (1) Reduce the induced voltage of the sheath: such as figure 1 As shown, 1 is a high-voltage and extra-high-voltage power cable, and the grounding form of the cable sheath is selected according to the actual line situation. 2 is the inner core of the coaxial cable, and 3 is the outer core of the coaxial cable. Through the vacuum circuit breaker 4, the inner core 2 of the coaxial cable and the outer core 3 of the coaxial cable are sequentially grounded to reduce the induced voltage of the sheath.

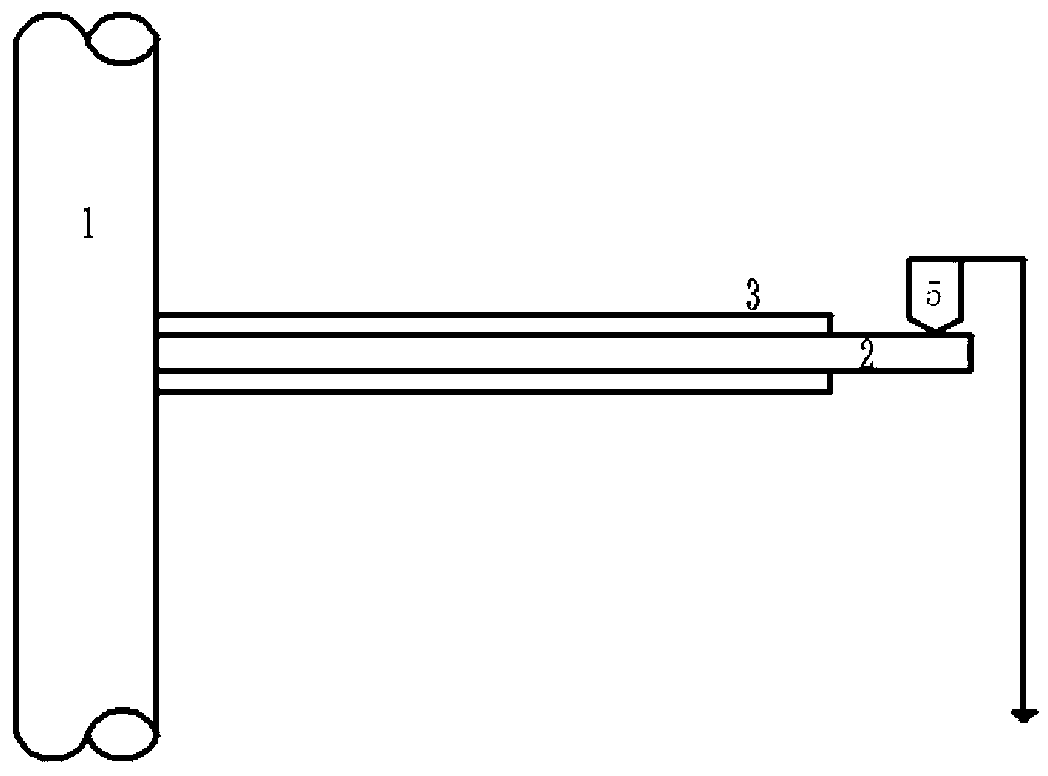

[0029] (2) Live construction protection: After step 1, use the puncture grounding device 5 to ground the inner core 2 of the coaxial cable to keep the inner core 2 of the coaxial cable equal to the ground during construction to protect the safety of construction personnel.

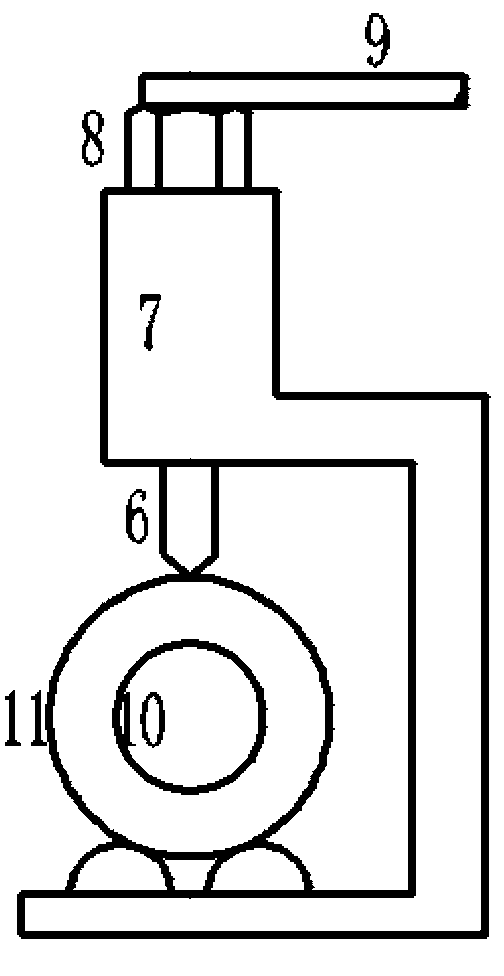

[0030] Piercing grounding equipment 5 such as image 3 shown. Rotate the knob 8 to adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com