Wedge-shaped strain clamp

A tension clamp and wedge-shaped technology, applied in the field of electric power, can solve the problems of loose wedge blocks, no self-locking structure, and inability to fix wires, etc., so as to prevent loosening and ensure line safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

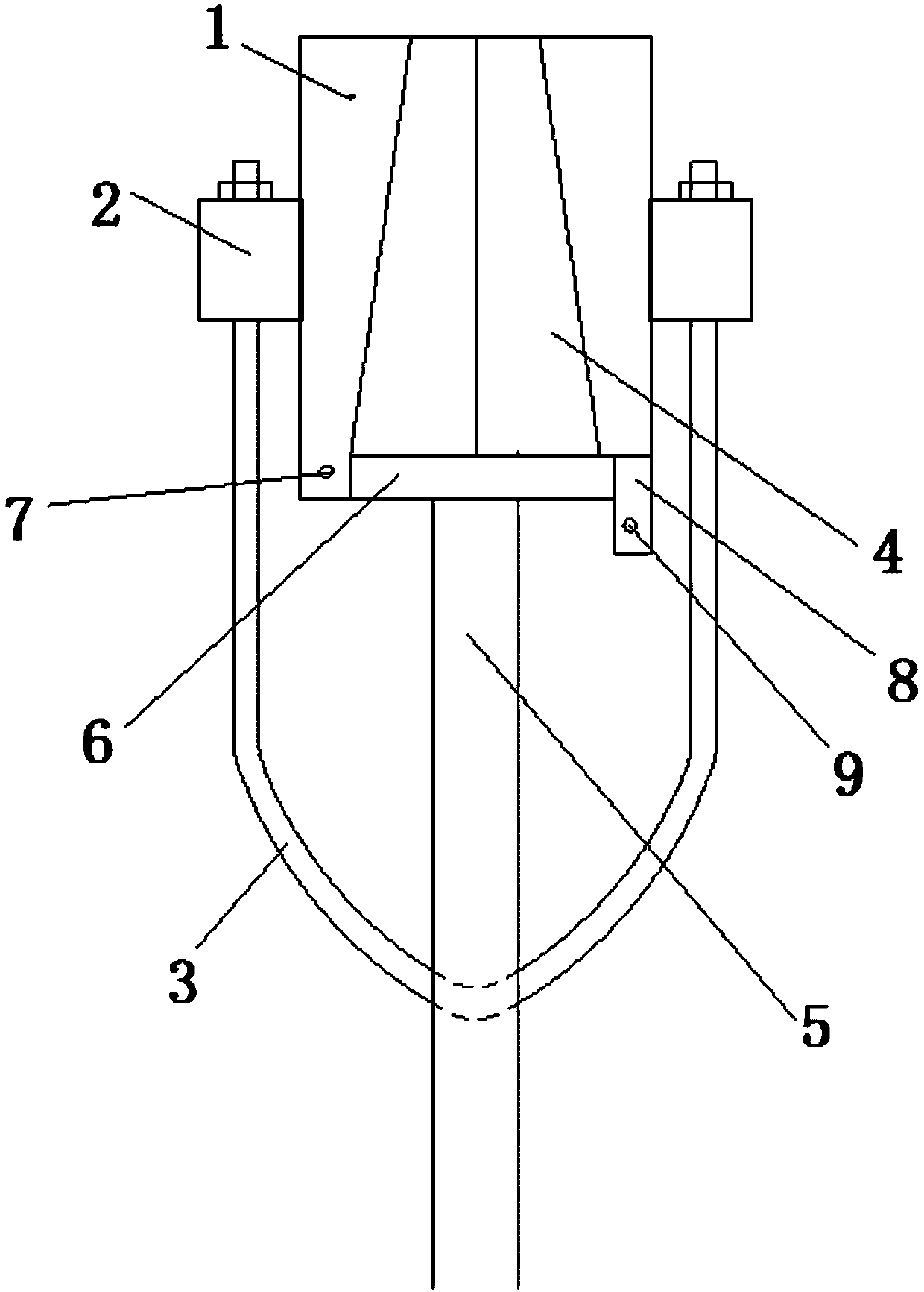

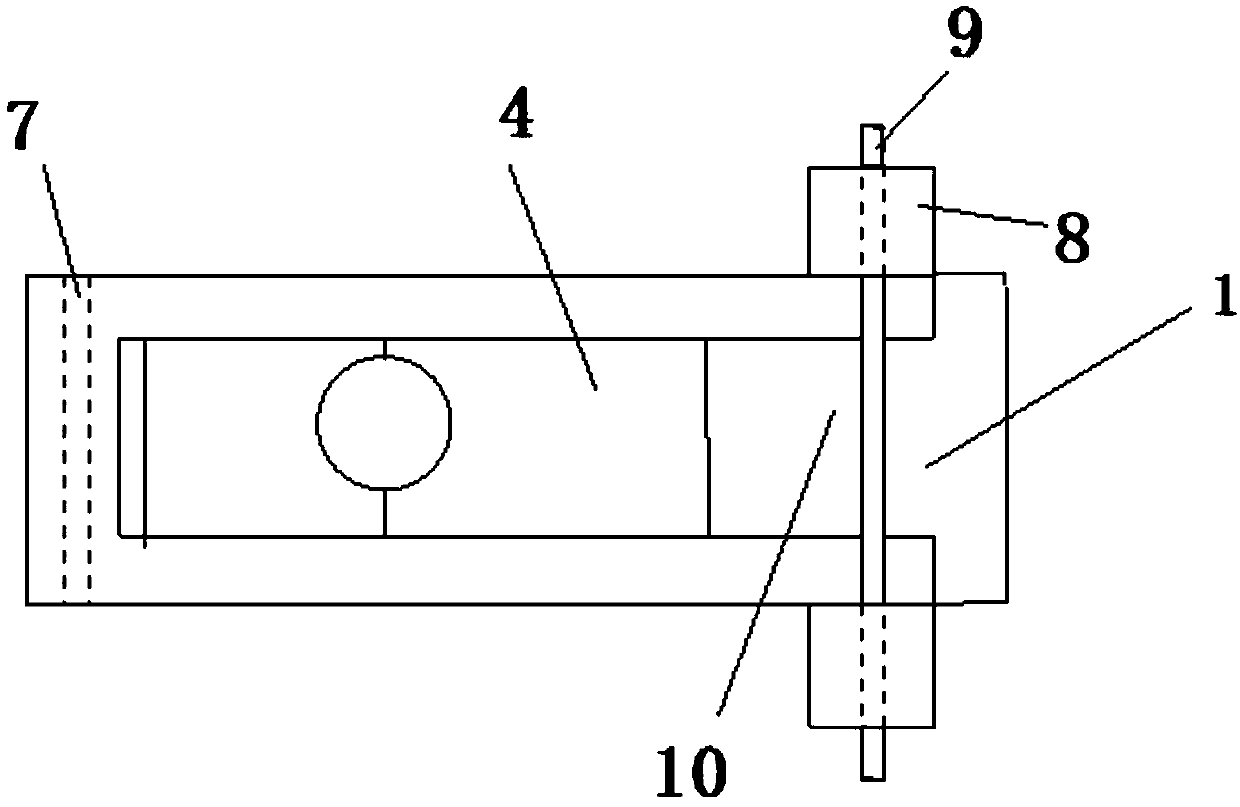

[0008] The present invention is specifically described below in conjunction with the accompanying drawings. As shown in the figure, the present invention includes a wire clip body 1, and wedge-shaped blocks 4 are arranged inside the wire clip body 1. The wedge-shaped blocks 4 are two groups, symmetrically arranged, and the outside of the wedge-shaped block and The wedge-shaped grooves on the inside of the clamp body are in contact, the inside of the wedge-shaped block is a semicircle, and the semi-circle inside the two wedge-shaped blocks tightens the outside of the cable 5; the two sides of the clamp body are provided with hanging lugs 2, and the The lug 2 and the hook 3 are fixed by bolts and nuts; the upper end of the clamp body is provided with a locking block 6, and the locking block 6 is U-shaped; one side of the locking block and the clamp body is passed through a rotating shaft 7 Axially connected, the locking block 6 corresponds to the groove 10 between the bosses 8 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com