Combined calender roll for papermaking calender

A combined calender roll technology, which is applied to paper machines, calenders, papermaking, etc., can solve the problems of roll body porosity, difficult feeding, sand holes, etc., so as to save metal materials, improve roll surface quality, and reduce roll damage. The effect of body weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

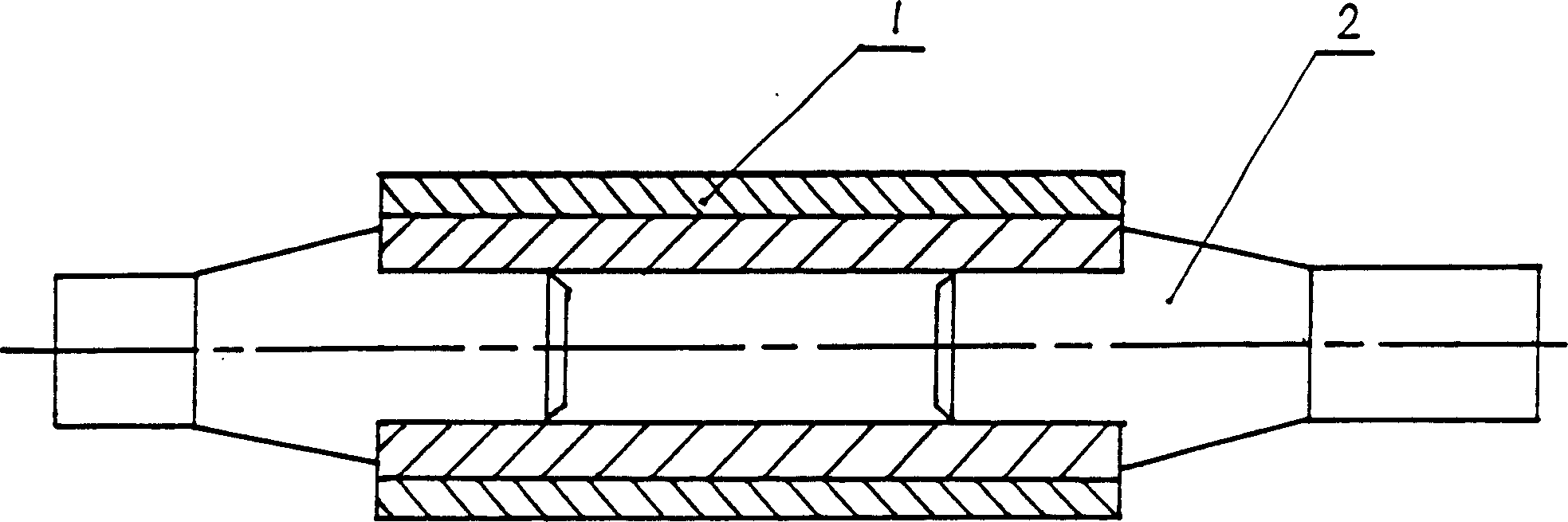

[0011] figure 1 It is a combined calender roll assembled by shrink-fitting. The roll sleeve 1 and roll shaft 2 are assembled and fixed by the interference to bear the working pressure.

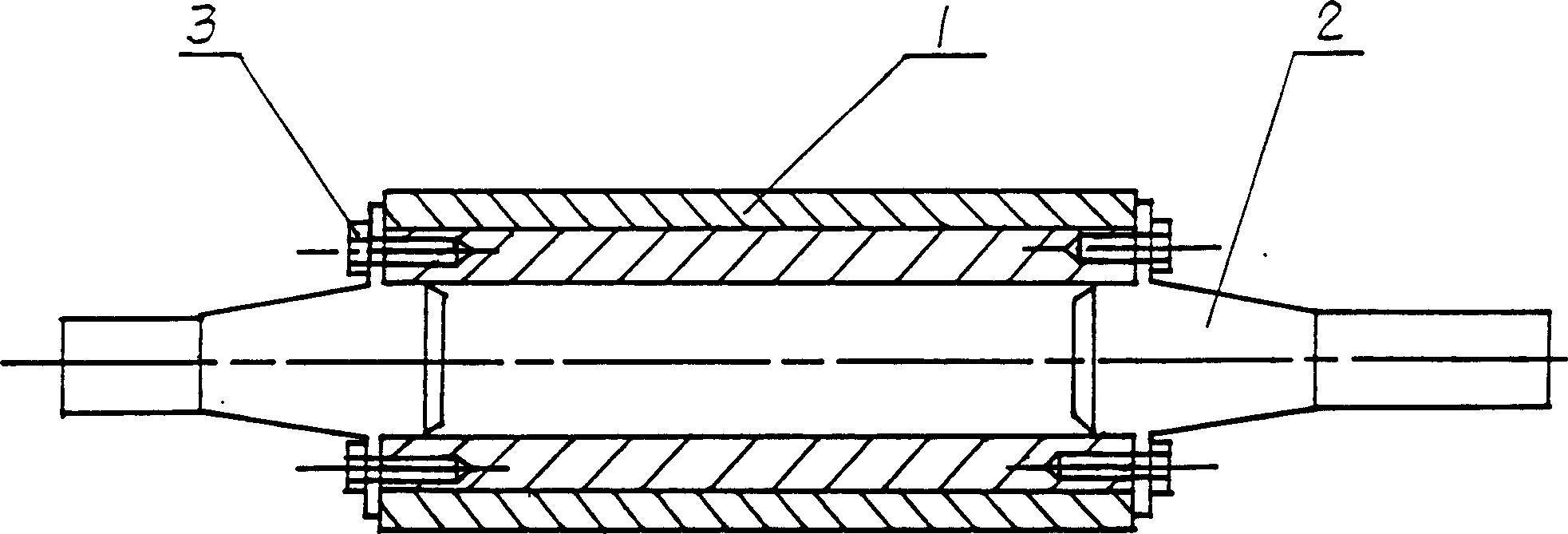

[0012] figure 2 It is a combined calender roll assembled in the way of 3 bolts, and the threaded hole is set on the inner metal part of the roll sleeve, which is convenient for processing.

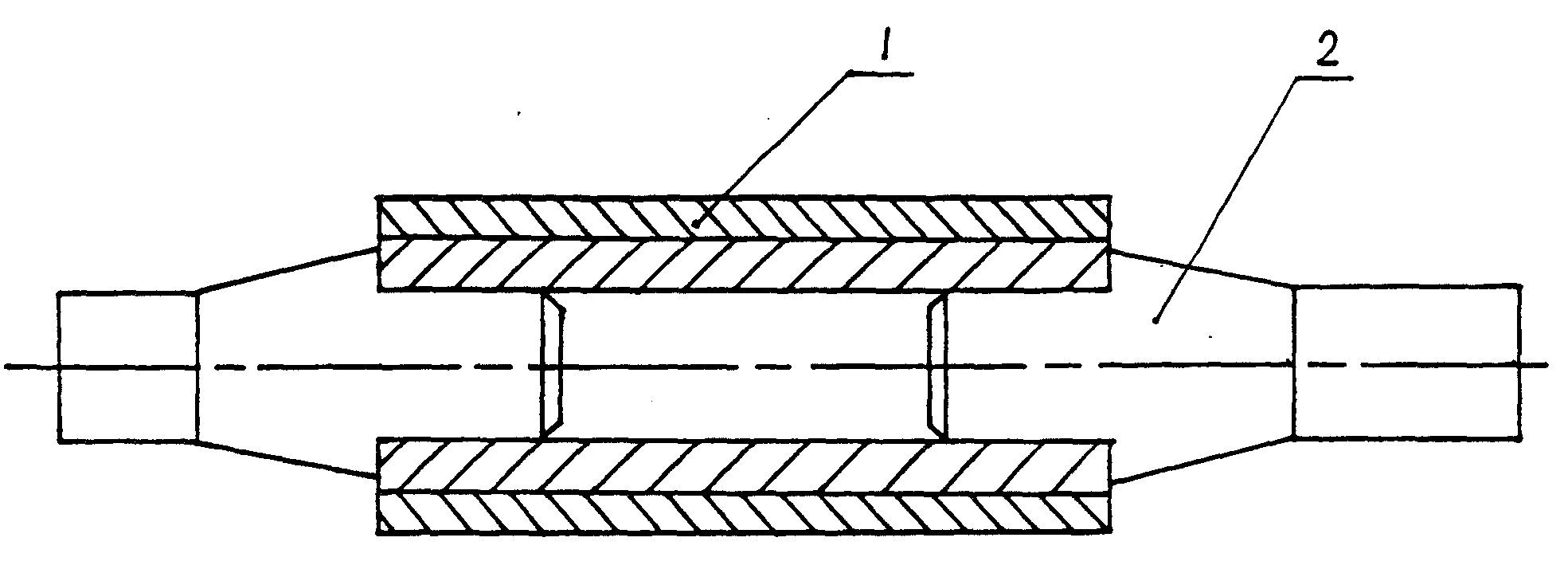

[0013] The combined calender rolls for papermaking calenders produced according to the above-mentioned technical scheme completely eliminate various casting defects of the roll body and neck, and significantly improve the quality of the calender rolls, especially for the longer roll surfaces that have been used more in recent years ( 2000mm~10000mm) calender rolls, the combined calender rolls of the present invention show great advantages.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com