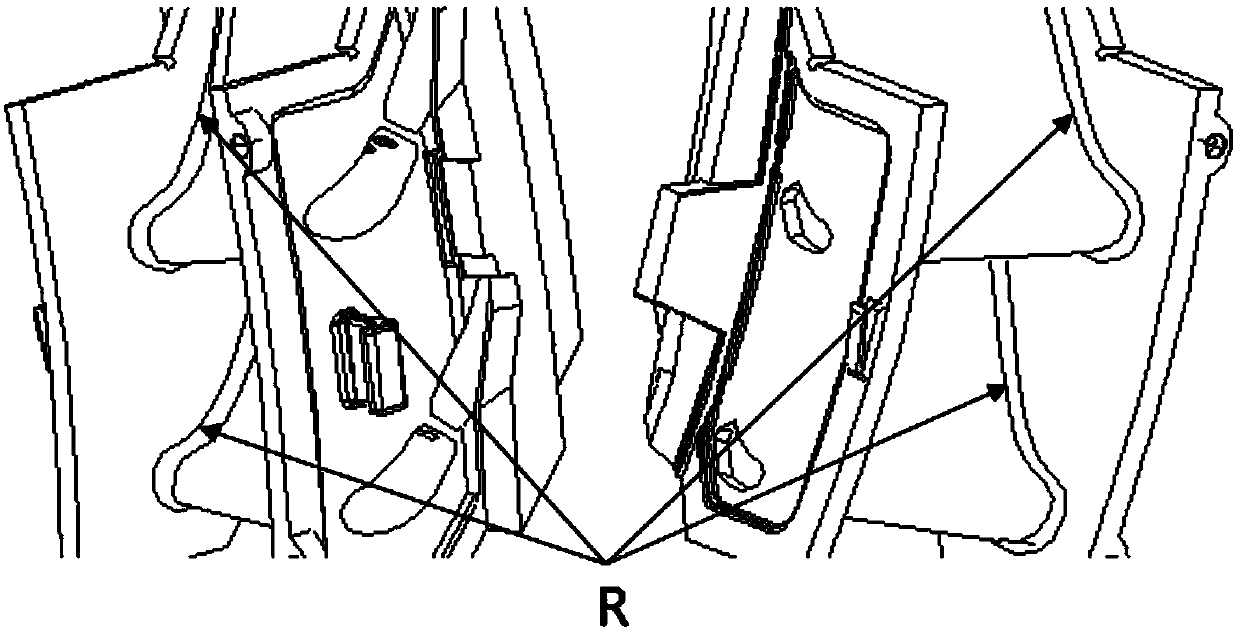

Method for eliminating looseness of joint R part between blade body and edge plate of large joint blade

A blade and edge plate technology, which is applied in the structural design and application field of shell casting, can solve the problems of large blade size, affecting the service life of the engine, and hidden quality problems, so as to achieve broad application prospects, eliminate loose defects, and reduce development costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

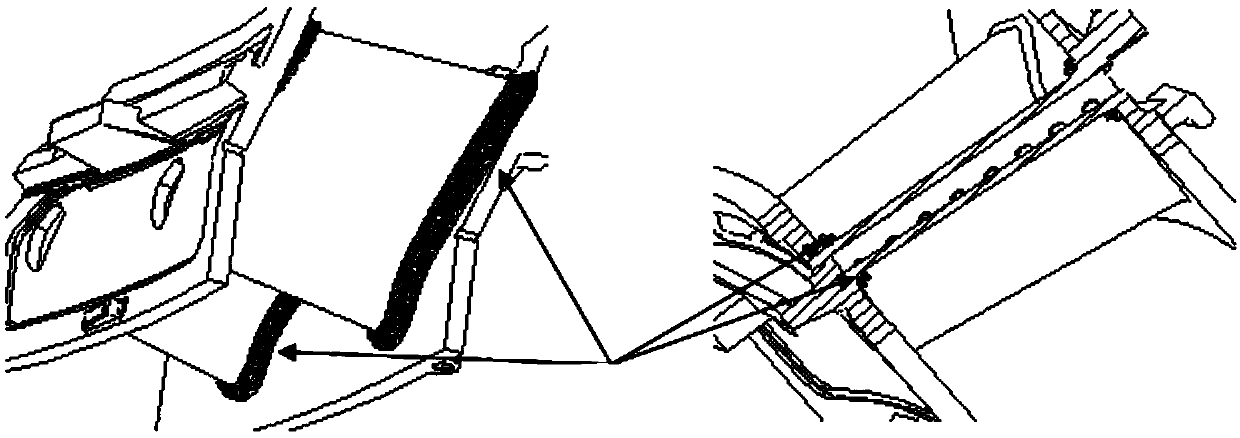

[0017] The specific steps of the method for eliminating the looseness of the R portion of the large conjoined blade body and the edge plate are as follows:

[0018] ①Preparation of iron shot coating: mix bauxite powder with viscosity of 10×10 -6 m 2 / s Silica sol is mixed into porridge-like paint, the mass ratio of bauxite powder and silica sol is 6:1, the paint is then added with iron pellets with a diameter of 1mm and mixed evenly to become iron pellet paint for later use, the ratio of paint and iron pellets is 1: 1;

[0019] ② The first four layers of the mold shell are coated by the general process. The general process is to dip the wax model module into the refractory material, sprinkle the granular refractory material, then dry and harden, and repeat according to the number of shell layers to make the refractory material Until the required thickness is reached, a shell is formed on the wax pattern module, and it is parked for a period of time to make it fully hardened,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com