Weighing device and method for weighing products

A weighing device and weighing technology, applied in the direction of measuring device, weighing vibration damping, weighing, etc., can solve the problems of time-consuming and troublesome, and achieve the effect of rapid determination and minimized risk of deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

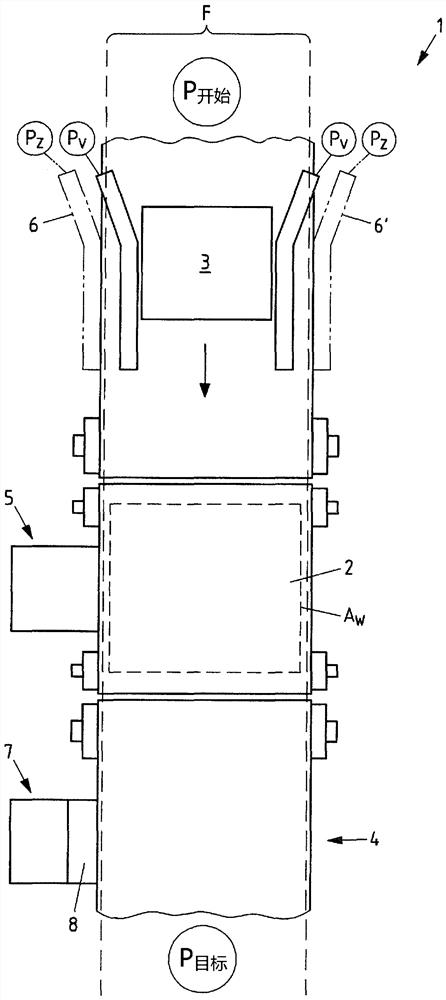

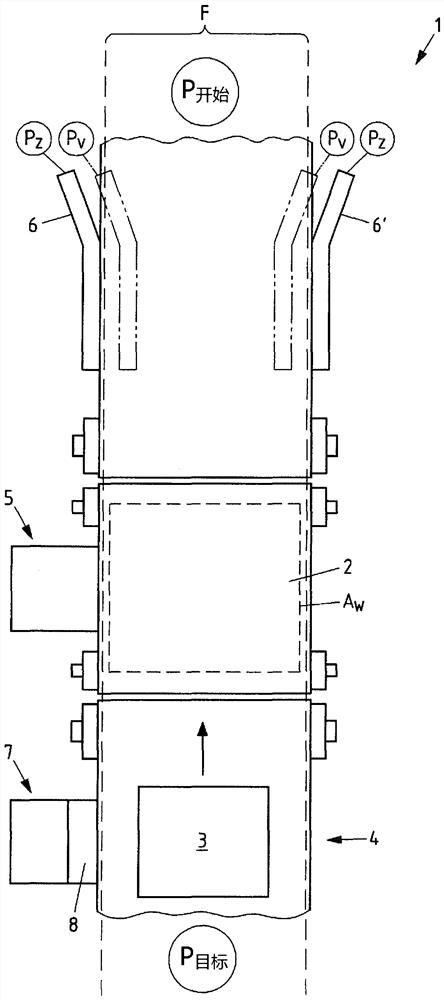

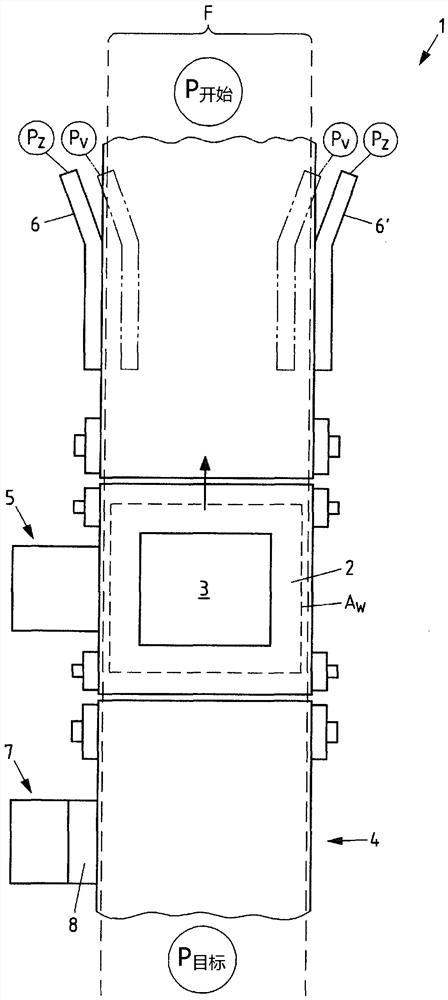

[0039] exist figure 1 A weighing device 1 in the form of a marking device or a checkweigher is schematically shown in plan view. The weighing device 1 has a function for weighing section A W A scale 2 for weighing a product 3 and a scale 2 for moving said product 3 along a conveying area F from a starting position P 开始 via the weighing section A W Transport to destination position P 目标 The conveying mechanism 4.

[0040] The conveying device 4 is in the present case a multi-piece belt conveyor, the balance 2 being integrated into a central section of the multi-piece belt conveyor.

[0041] The weighing device 1 also has a control device 5 which in particular controls the conveying device 4 , in particular the speed and the direction of travel of the conveying device 4 . The control takes place in a time- and / or path-dependent manner and / or taking position data of the correspondingly moved product into account. The position data can be determined, for example, via an opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com