Apparatus and method for treating a surface of a substrate

A substrate and action technology, applied to the surface device, to deal with the surface field of the substrate, can solve the problems of complex mechanical structure of the nozzle head, inability to withstand precursors uniformly, and large mechanical force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

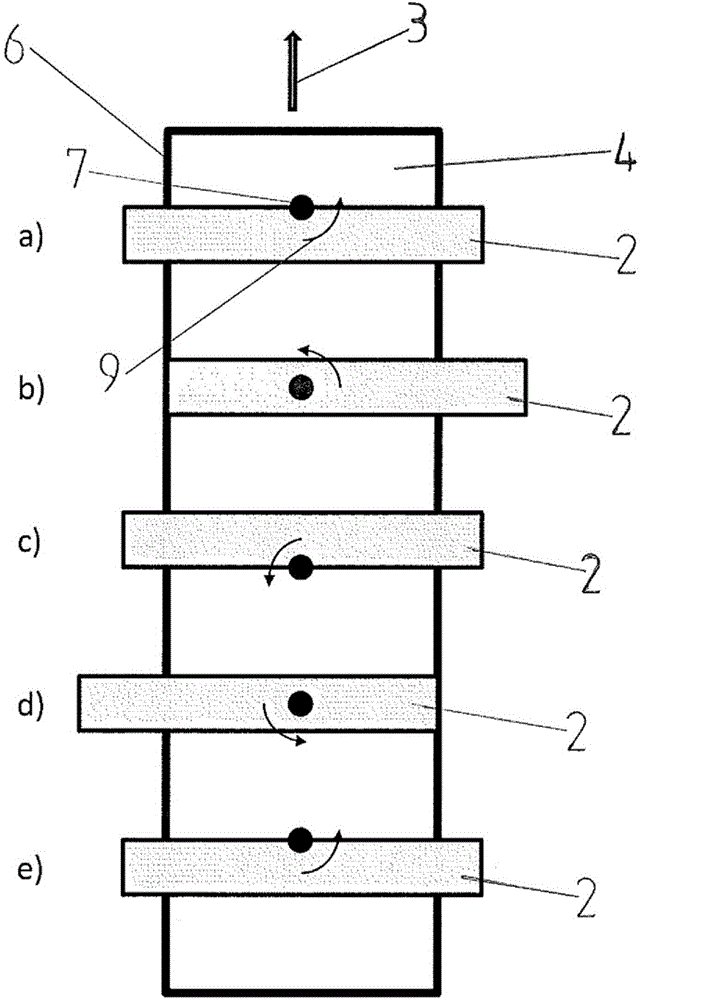

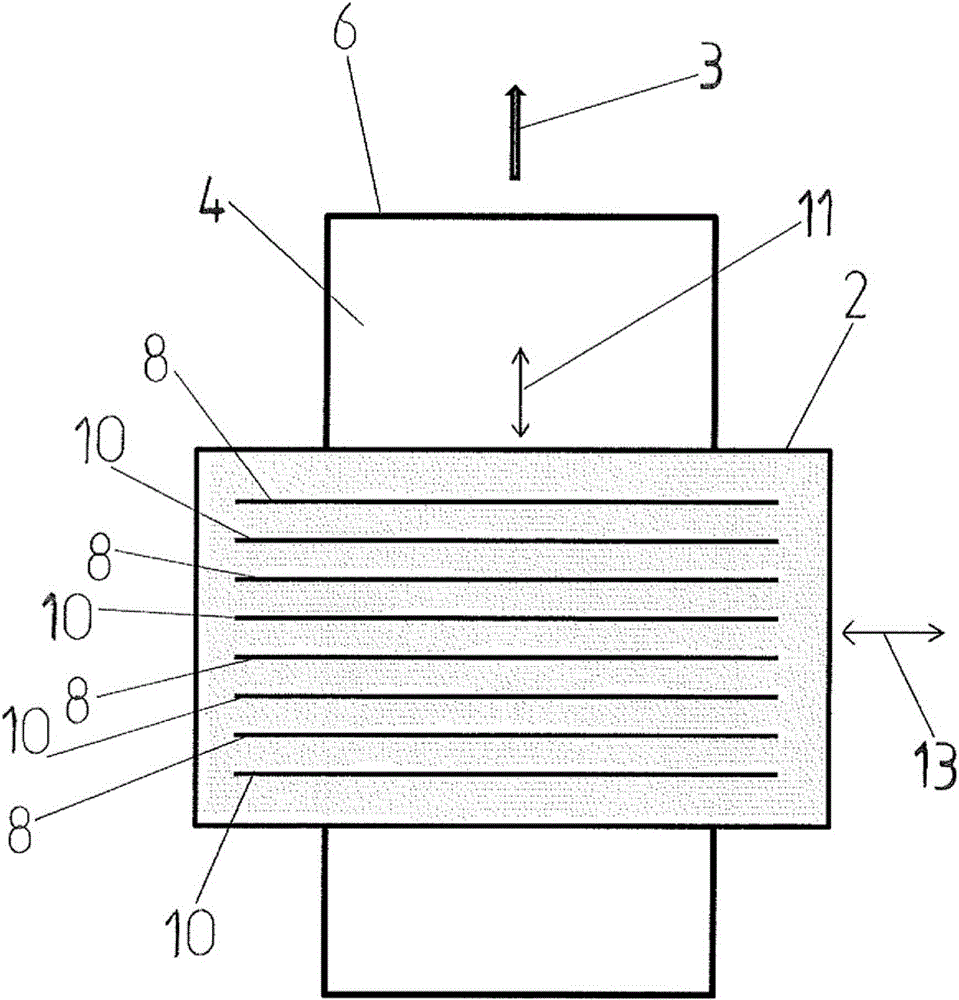

[0014] figure 1 A schematic diagram of one embodiment of an apparatus is shown for subjecting a surface 4 of a substrate 6 to successive surface reactions of at least a first precursor and a second precursor according to the principles of ALD. The apparatus comprises a nozzle head 2 having: one or more first precursor nozzles for subjecting a surface 4 of a substrate 6 to a first precursor; and one or more nozzles for subjecting the surface 4 of a substrate 6 to A second precursor nozzle subjected to a second precursor. The nozzle head 2 can also be provided with a plurality of purge gas nozzles and possibly a plurality of discharge nozzles, which are arranged between the respective precursor nozzles. However, it should be noted that by providing the precursor nozzle and the purge gas nozzle with discharge ports for discharging the precursor and purge gas, the discharge nozzle can be omitted. In one embodiment, the nozzle head 2 sequentially includes precursor nozzles, purge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com