Defect detection method and defect detection system

A defect detection and defect technology, applied in optical testing of defects/defects, measurement devices, material analysis by optical means, etc. The effect of reducing the number, reducing the time of scanning, increasing the capture capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

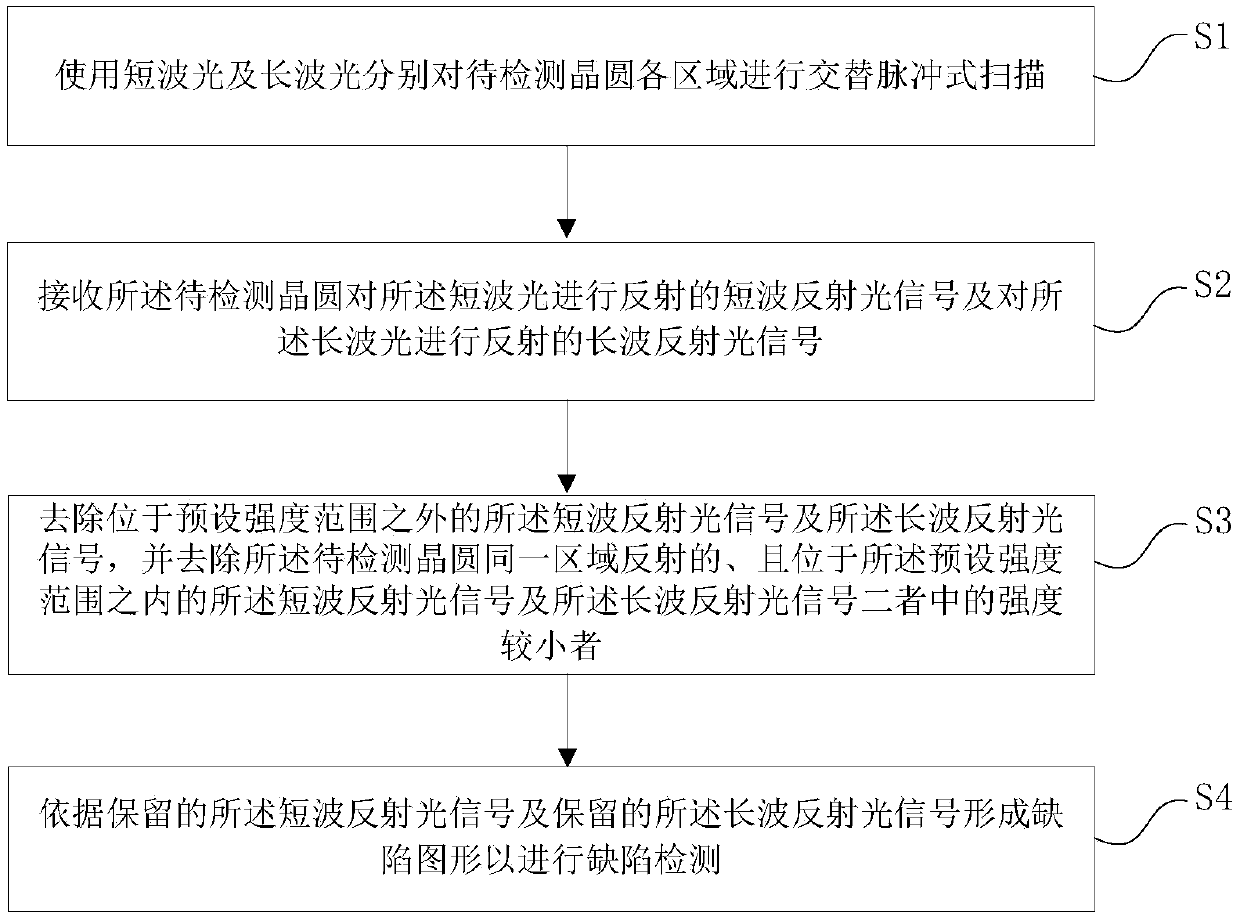

[0066] see figure 1 , the present invention provides a defect detection method, the defect detection method comprises the following steps:

[0067] 1) Use short-wavelength light and long-wavelength light to perform alternate pulse scanning on each area of the wafer to be inspected;

[0068] 2) receiving a short-wave reflected light signal that reflects the short-wave light and a long-wave reflected light signal that reflects the long-wave light by the wafer to be detected;

[0069] 3) removing the short-wave reflected light signal and the long-wave reflected light signal outside the preset intensity range, and removing all light signals reflected from the same area of the wafer to be inspected and within the preset intensity range The intensity of the short-wave reflected light signal and the long-wave reflected light signal is smaller;

[0070] 4) forming a defect pattern according to the retained short-wave reflected light signal and the retained long-wave reflected li...

Embodiment 2

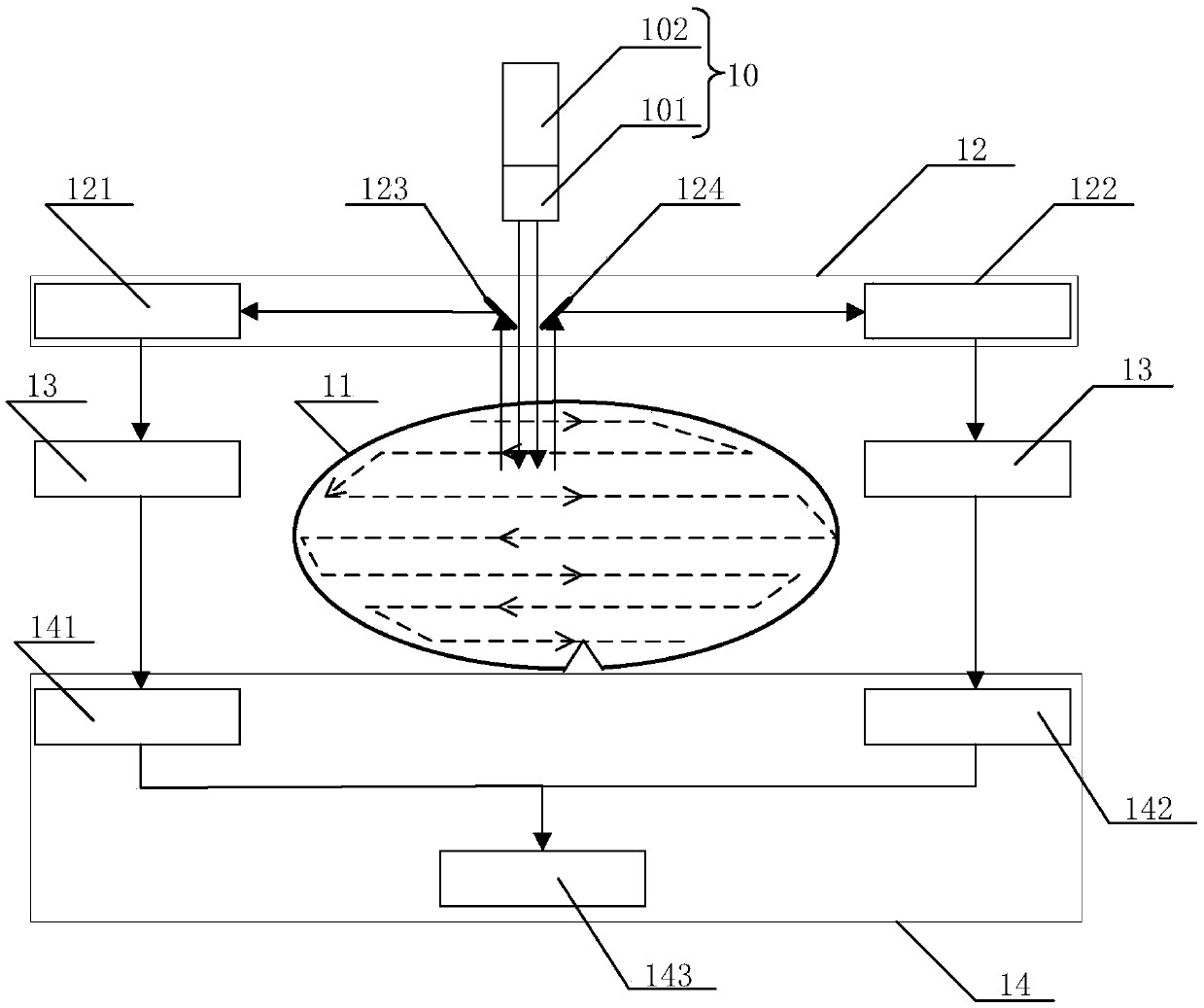

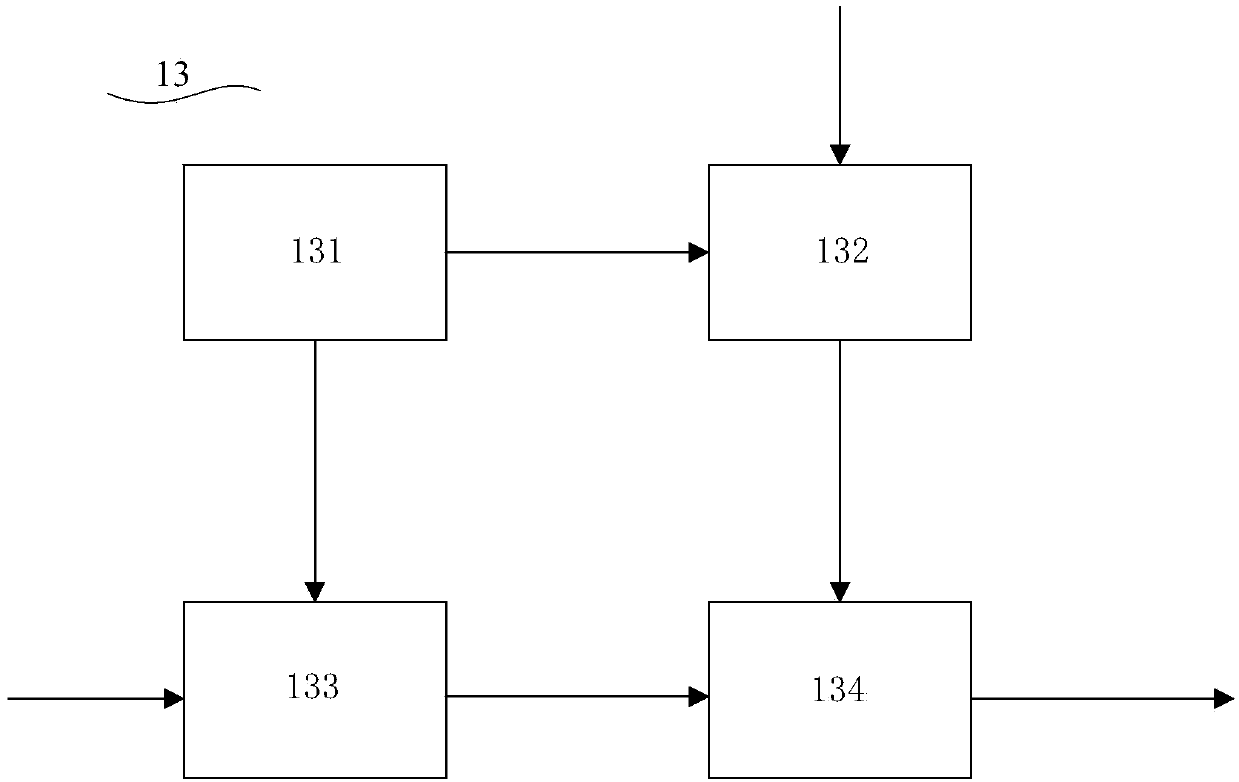

[0089] see figure 2 and image 3 The present invention also provides a defect detection system, which includes: a light source device 10, a detection device 12, a comparison processing device 13, and an imaging detection device 14; wherein, the light source device 10 is located on the wafer 11 to be detected above, the light source device 10 includes a short-wave light source 101 and a long-wave light source 102, and the light source device 10 is used to alternately emit short-wave light and long-wave light to perform alternate pulse scanning on each area of the wafer 11 to be inspected, that is The short-wave light source 101 and the long-wave light source 102 alternately emit corresponding light; the detection device 12 is located on the upper side of the wafer 11 to be inspected, and the detection device 12 is used to receive the wafer 11 to be inspected The short-wave reflected light signal that reflects the short-wave light and the long-wave reflected light signal tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com