Connection adapter for turbomachine and turbomachine

A technology of adapters and turbines, applied in the direction of machines/engines, gas turbine devices, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

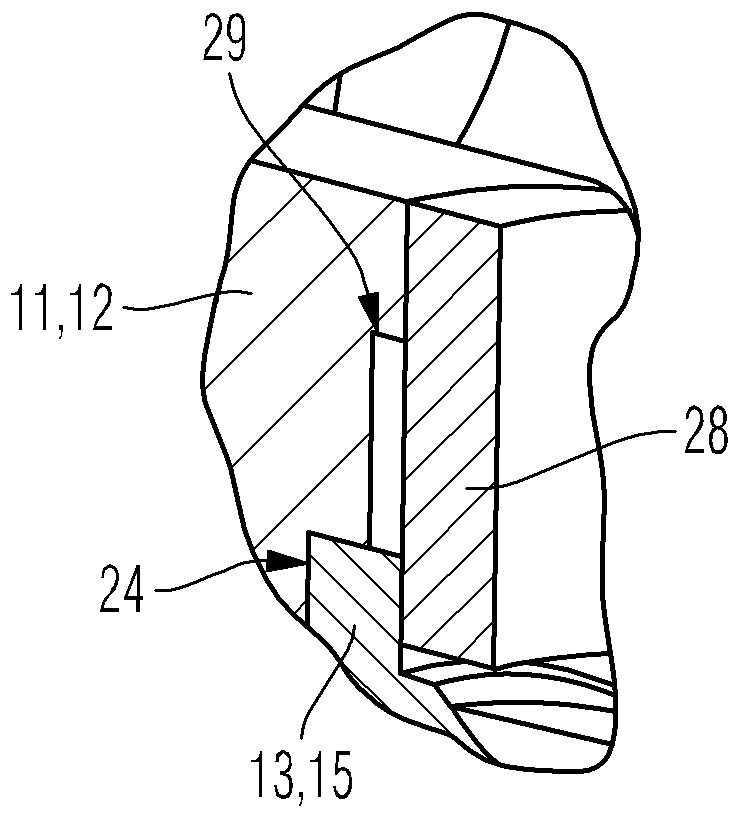

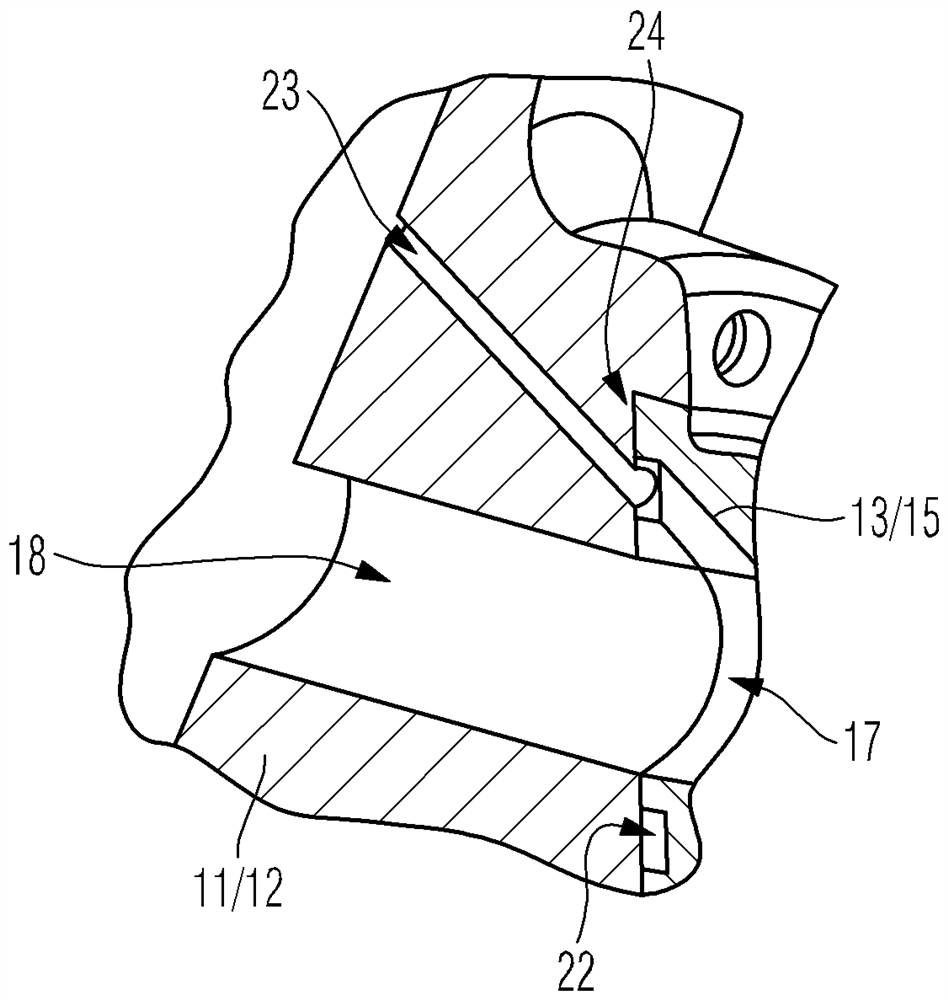

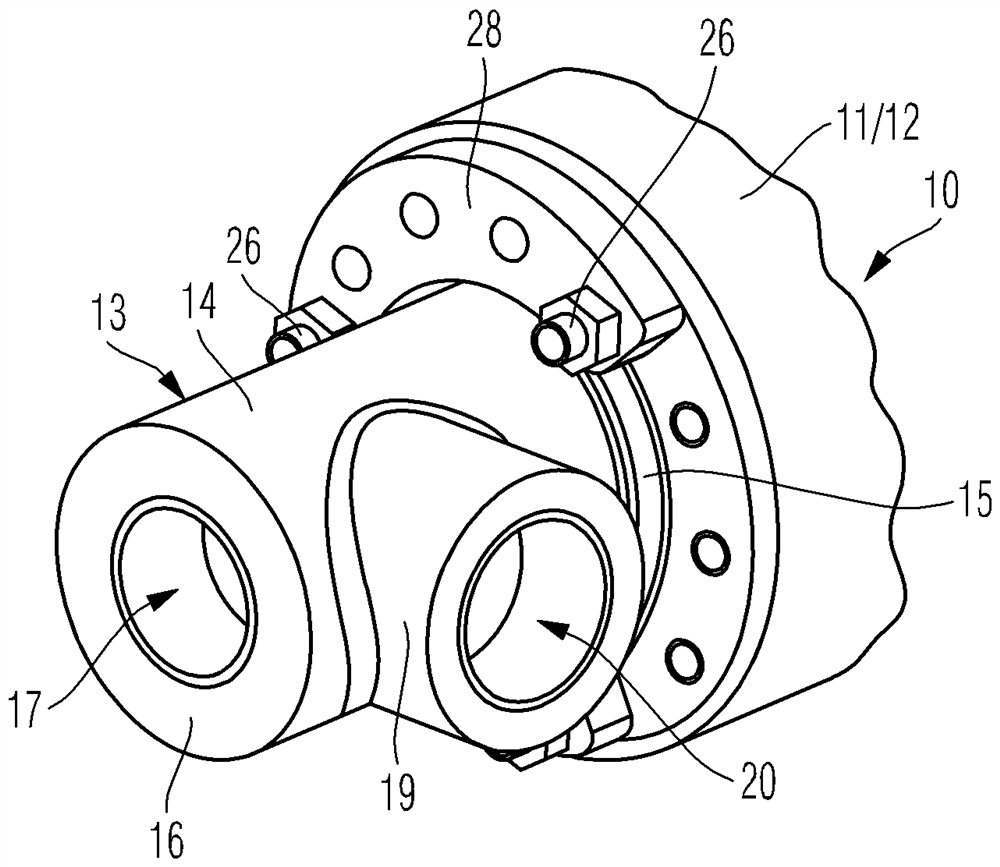

[0018] figure 1 A perspective excerpt of a turbine 10 according to the invention is shown in the region of the turbine inflow housing 11 of the turbine 10, wherein a connection flange 12 is formed on the turbine inflow housing 11 and a connection adapter 13 according to the invention is mounted on the connection flange 12 on.

[0019] The connection adapter 13 comprises a main body 14 with a first axial section 15 connecting the connection adapter 13 to the connection flange 12 of the turbine housing 11 and oppositely positioned to connect a not shown dry cleaning agent feed line. to the second axial section 16 of the connection adapter 13 . The two axial sections 15 , 16 can also be referred to as axial end sections. It is located at opposite axial ends of the main body 14 .

[0020] Via the first axial section 15 of the main body 13 the connection adapter 13 is connected in this way to the connection flange 12 and correspondingly to the turbine housing 11 in the following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com