Tunnel automatic fire extinguishing machine

A technology for fire extinguishers and tunnels, applied in fire rescue and other directions, can solve the problems of limited fire extinguishing ability of fire extinguishers, inability to extinguish fire by vehicles, and danger to personnel, so as to avoid low fire extinguishing effect and ensure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

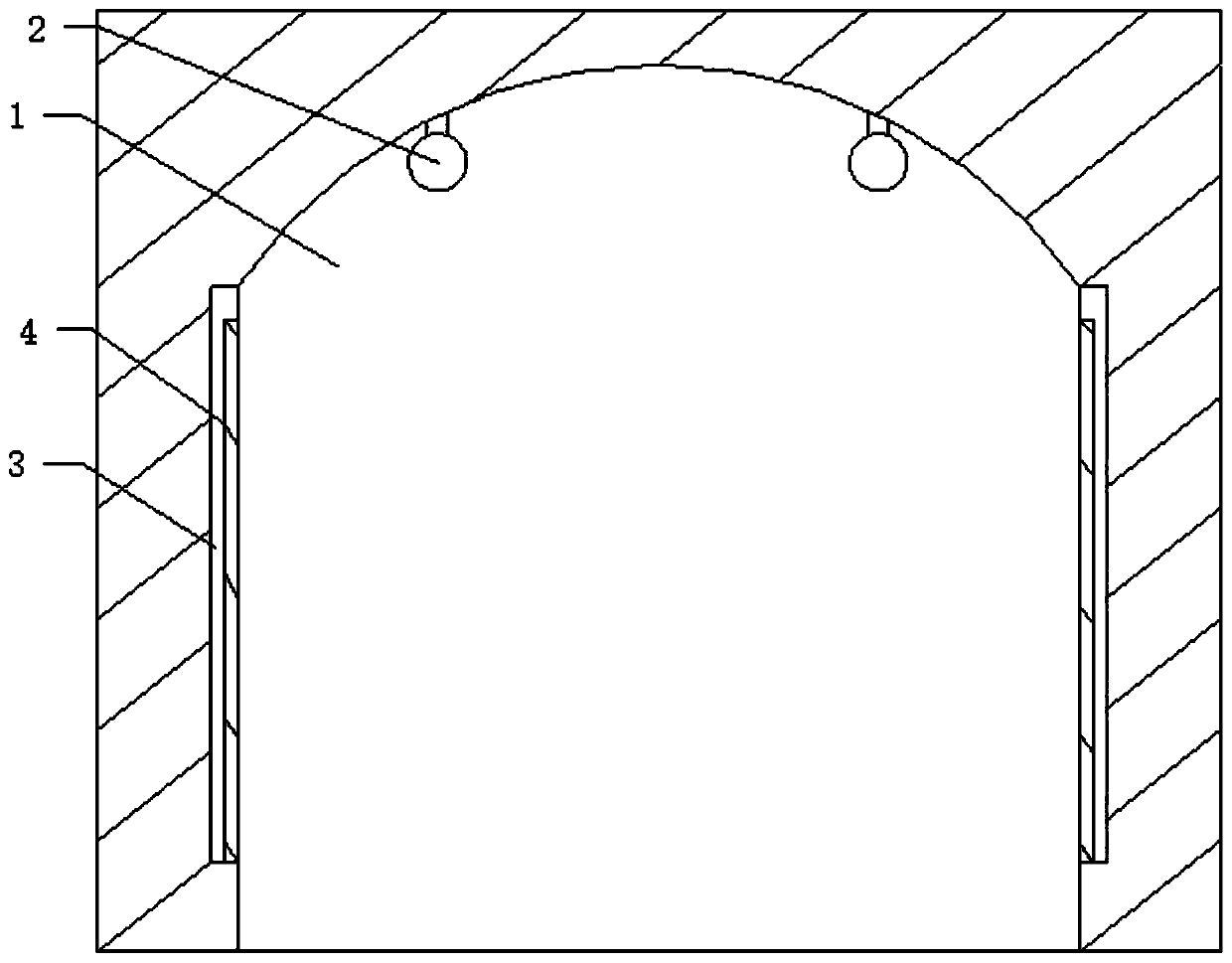

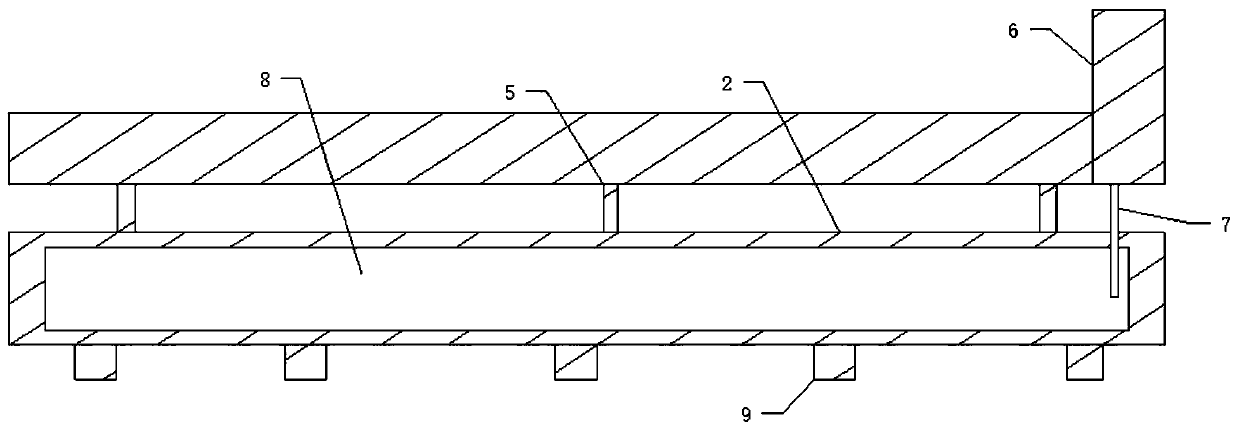

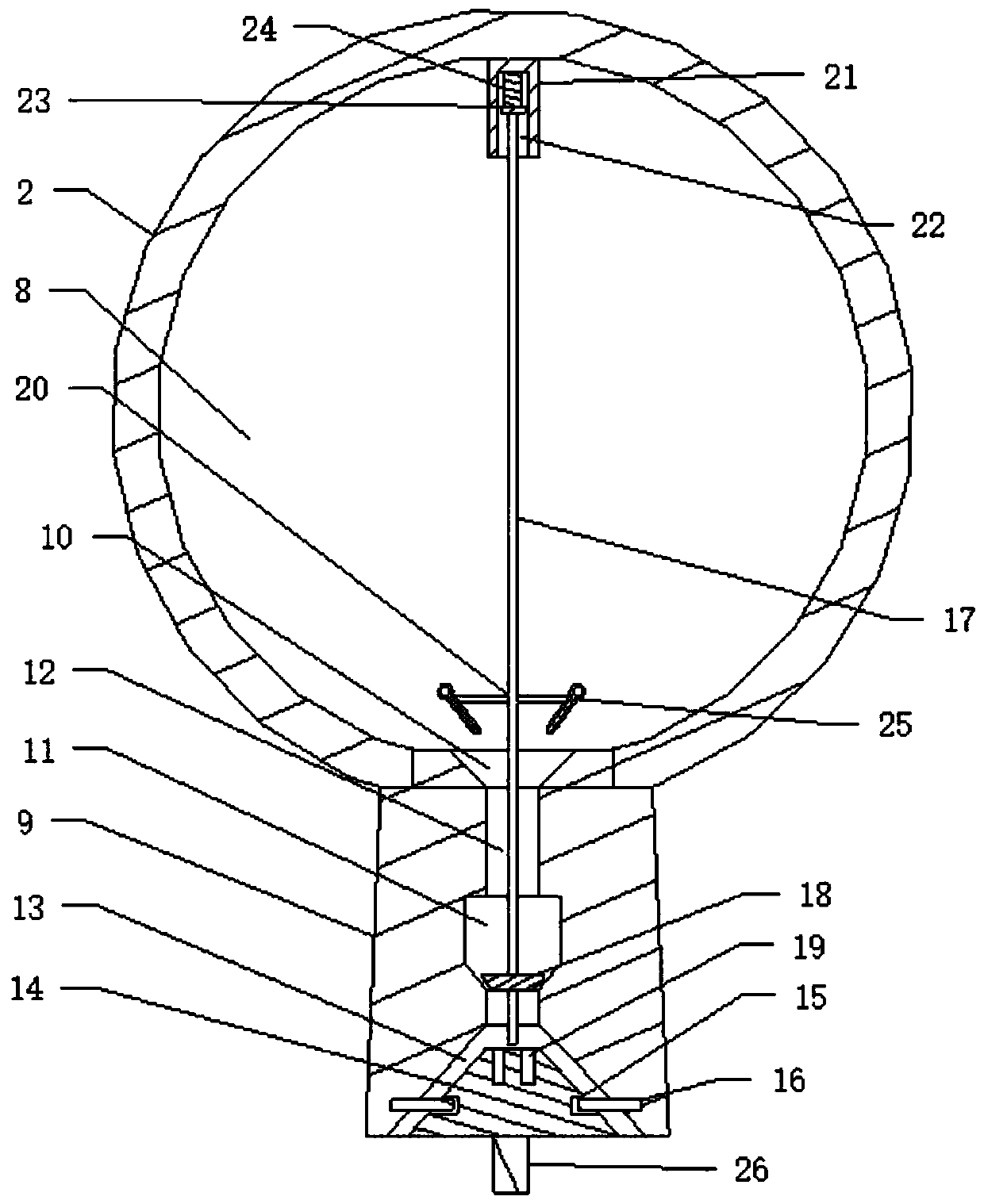

[0027] Such as Figure 1 to Figure 6 As shown, a tunnel automatic fire extinguisher includes a tunnel 1, and two dust pipes 2 are arranged on the top of the tunnel 1, and a dust chamber 8 is respectively arranged in the dust pipe 2, and a fire extinguishing chamber 8 is arranged in the dust chamber 8. Dust, the dust pipeline 2 is respectively provided with a plurality of butt ends 9, and each of the butt ends 9 is respectively provided with a first communication hole 12 corresponding to the dust chamber 8, and the butt ends 9 are respectively provided with a first sliding shaft 17 sliding in the first communication hole 12, the first sliding shaft 17 is sliding in the dust chamber 8, and the first sliding shaft 17 is respectively provided with A sealing head that controls the opening and closing of the first communication hole 12, and the butt end 9 is respectively provided with a butt groove 11 corresponding to the first communication hole 12, and the butt groove 11 is respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com