Support assembly equipment of movable-type hydraulic lifting platform

A hydraulic lifting platform, mobile technology, applied in the field of lifting platforms, can solve the problems of inconvenient impact force, inconvenient auxiliary platform lifting, inconvenient mobile platform guidance, etc., to achieve the effect of buffering impact force and preventing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

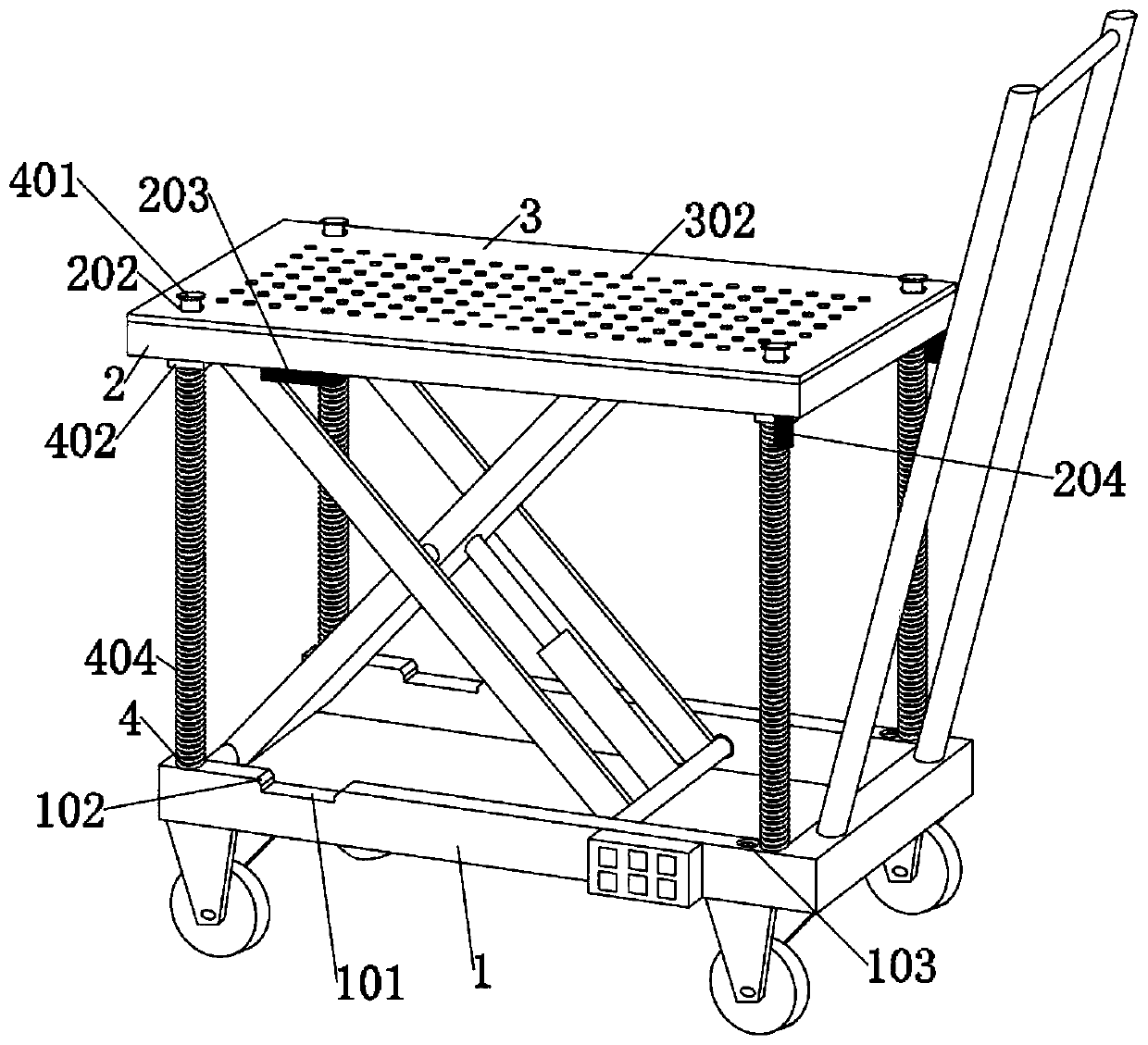

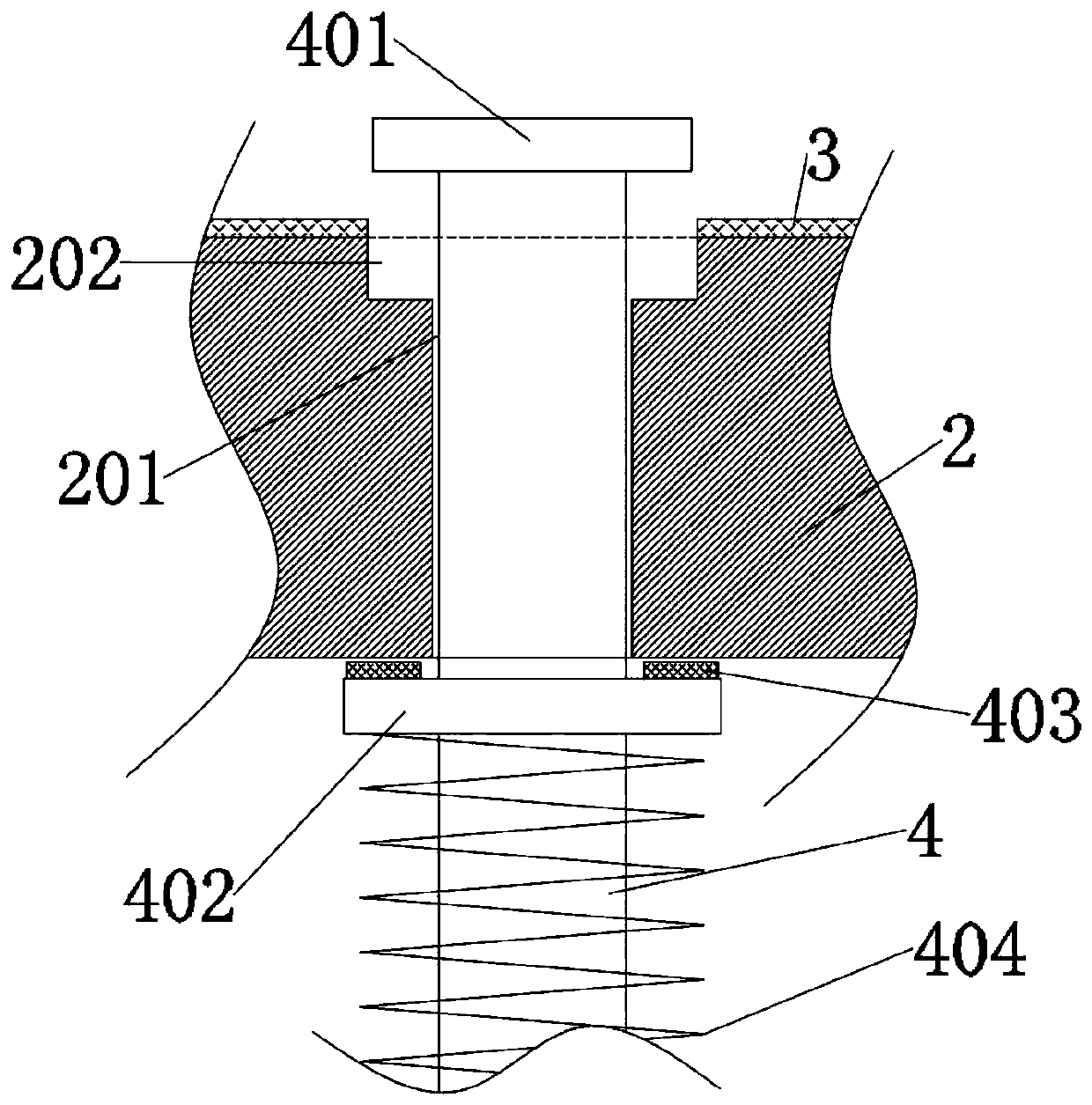

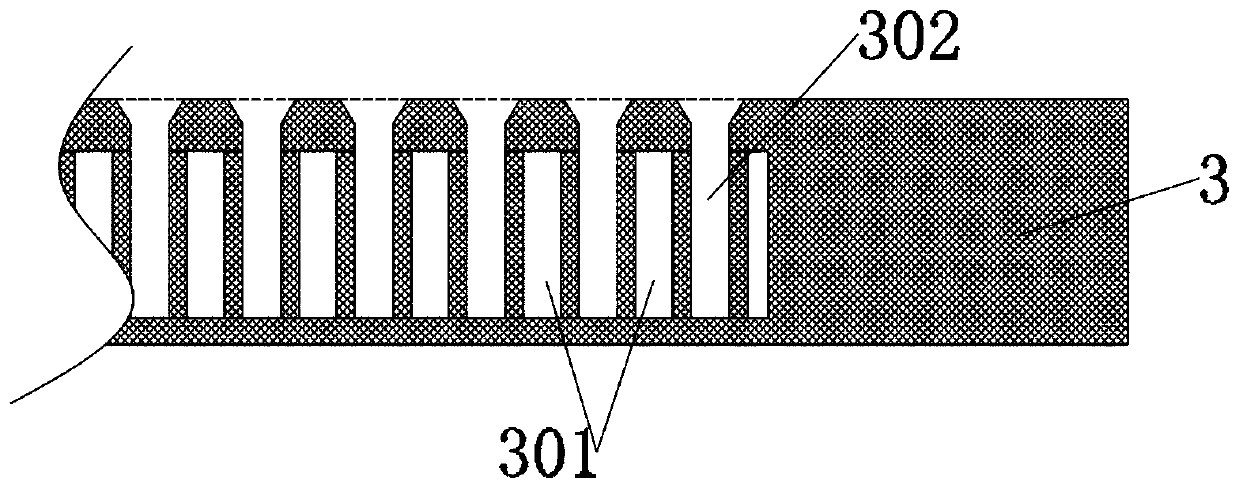

[0024] as attached figure 1 to attach image 3 Shown:

[0025] The present invention provides a support component device for a mobile hydraulic lifting platform, including a main body 1, a card slot 101, a guide edge 102, an insertion hole 103, a receiving part 2, a moving hole 201, an insertion hole 202, an insertion block 203, and an insertion column 204, anti-slip part 3, inner chamber 301, contact hole 302, guide rod 4, baffle plate 401, force plate 402, buffer block 403 and support spring 404; Described main body 1 is rectangular structure, and the bottom of this main body 1 is installed with Move the wheel, moreover, the top right side of the main body 1 is fixedly equipped with a push rod, and the inside of the top of the main body 1 is connected with the electric cylinder and the flip bar and the bottom of the receiving part 2 through the connecting rod; the bottom of the receiving part 2 Both sides of the right end are fixedly connected with cylindrical rubber posts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com