Wedge locker adopting forward and reverse thread transmission locking manner

A technology of wire transmission and locker, which is applied in the direction of friction clamping detachable fasteners, connecting components, mechanical equipment, etc., and can solve the problem of small wedge locker size, locking failure, huge energy and cost, etc. Problems, to achieve the effect of stop design and reduction of rotation times, increase of locking breaking torque, and reduction of fault repair time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

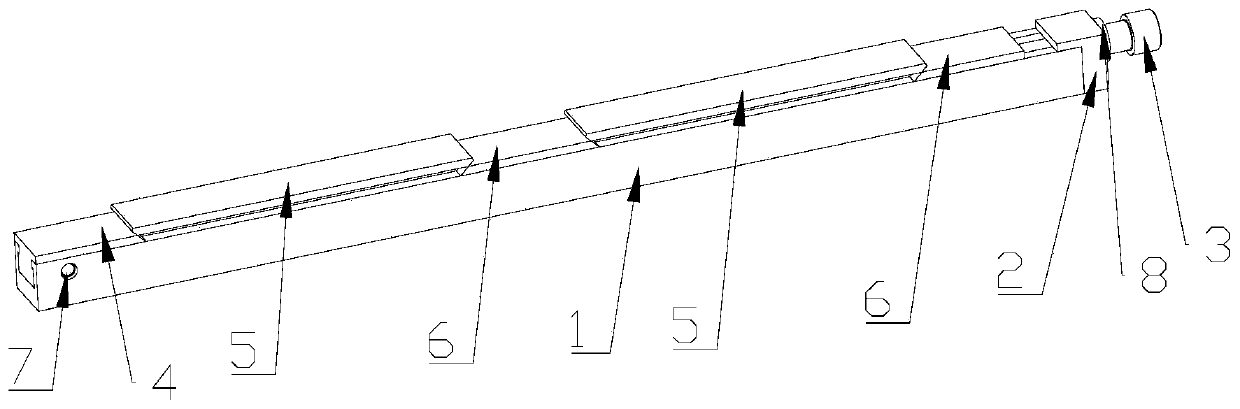

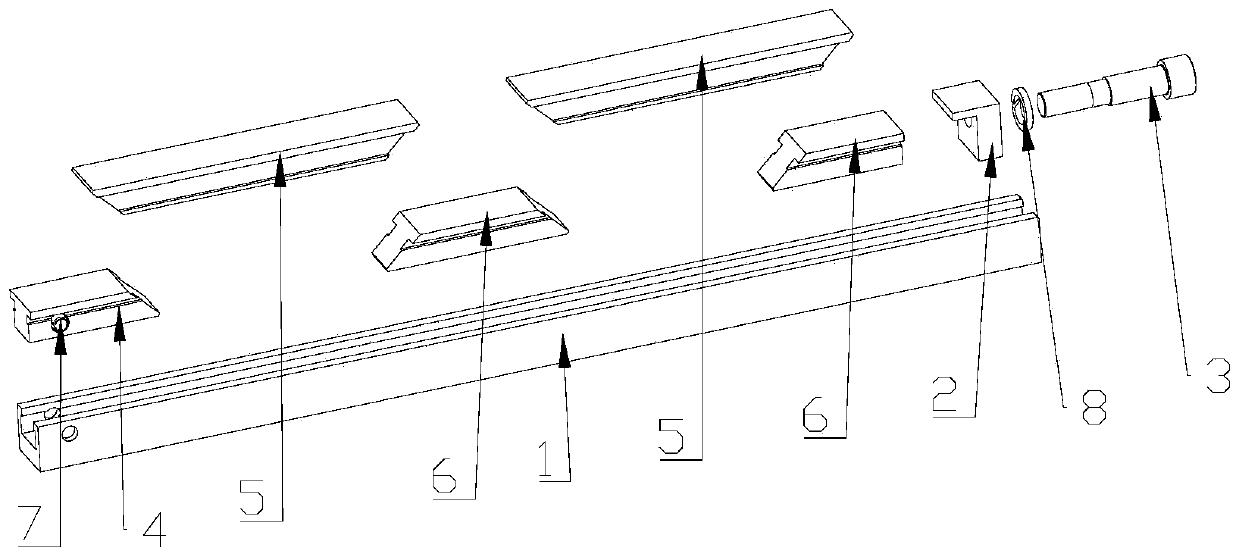

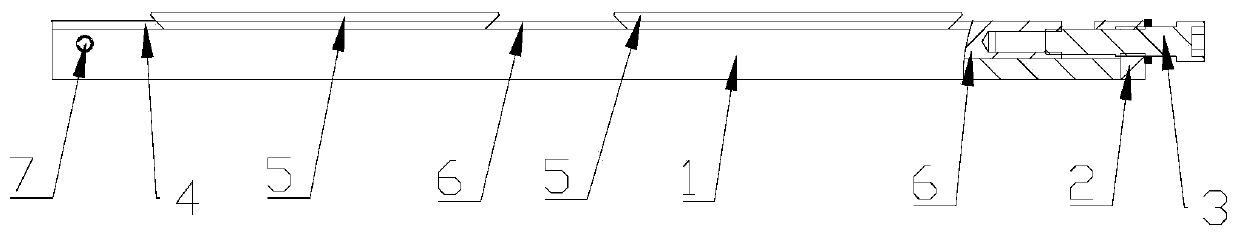

[0043] like Figure 1-8 As shown, a wedge locker of the positive and negative wire transmission locking method in this embodiment includes a trunk groove body 1, an anti-off block 2, a screw 3, a fixed wedge block 4 and a movable wedge block group;

[0044] The fixed wedge block 4 is fixedly connected to one end of the trunk tank body 1 in the length direction through the cotter pin 7, the movable wedge block group is connected to the trunk tank body 1 in the length direction, and one end of the movable wedge block group cooperates with the fixed wedge block 4;

[0045] The moving wedge block group includes a moving wedge block 5 and a sliding wedge block 6 that cooperate with each other. There are more than one moving wedge block 5 and sliding wedge block 6, which are connected in sequence in the length direction of the trunk groove body 1. At least one sliding wedge block 6 is connected At the other end of the trunk tank 1 in the length direction and slide along the length dir...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap