Method and system of predictive maintenance of a textile machine

A textile, predictive technology for textiles and paper, testing/monitoring control systems, general control systems, etc., to solve problems such as unclear data correlations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

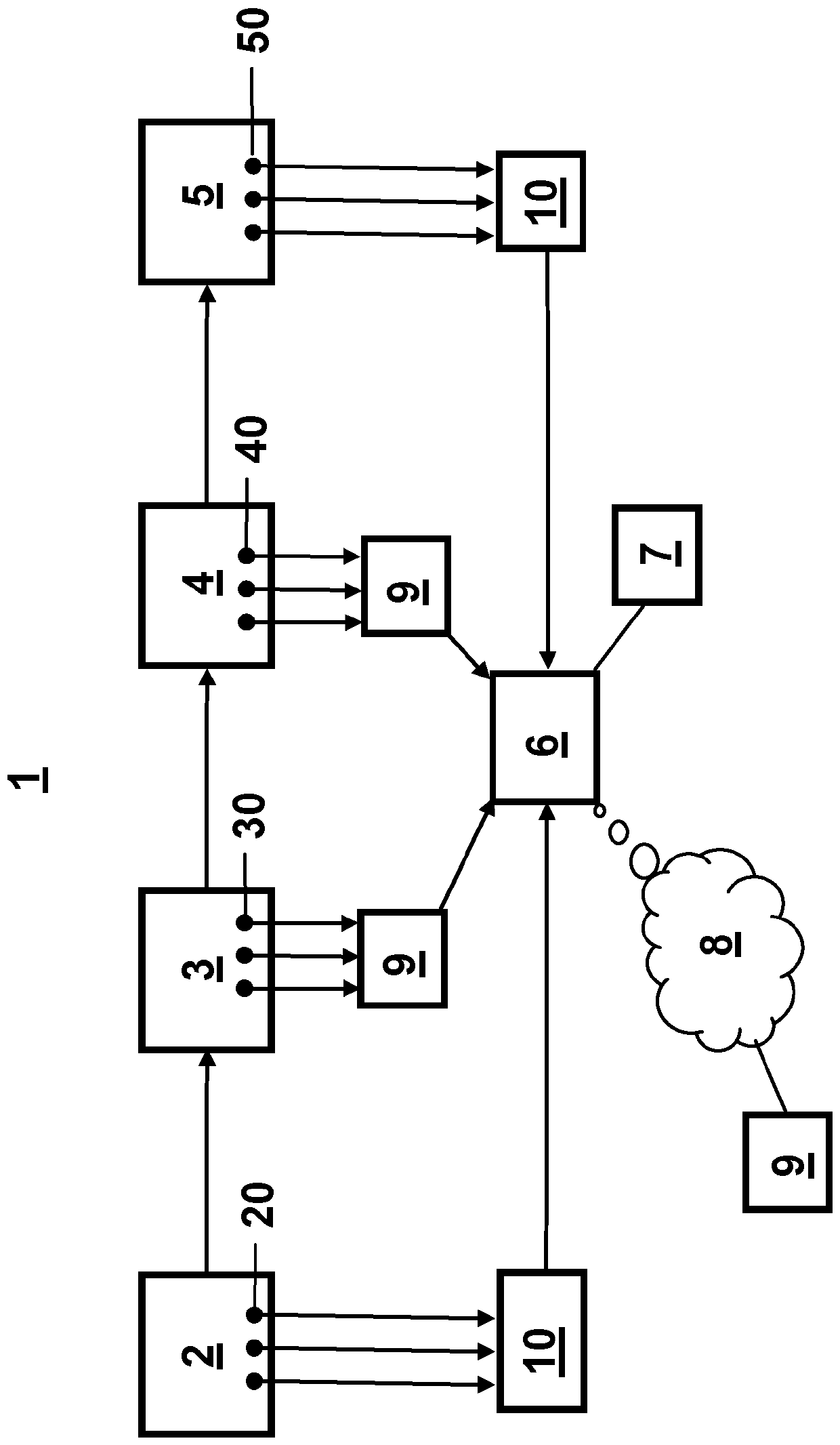

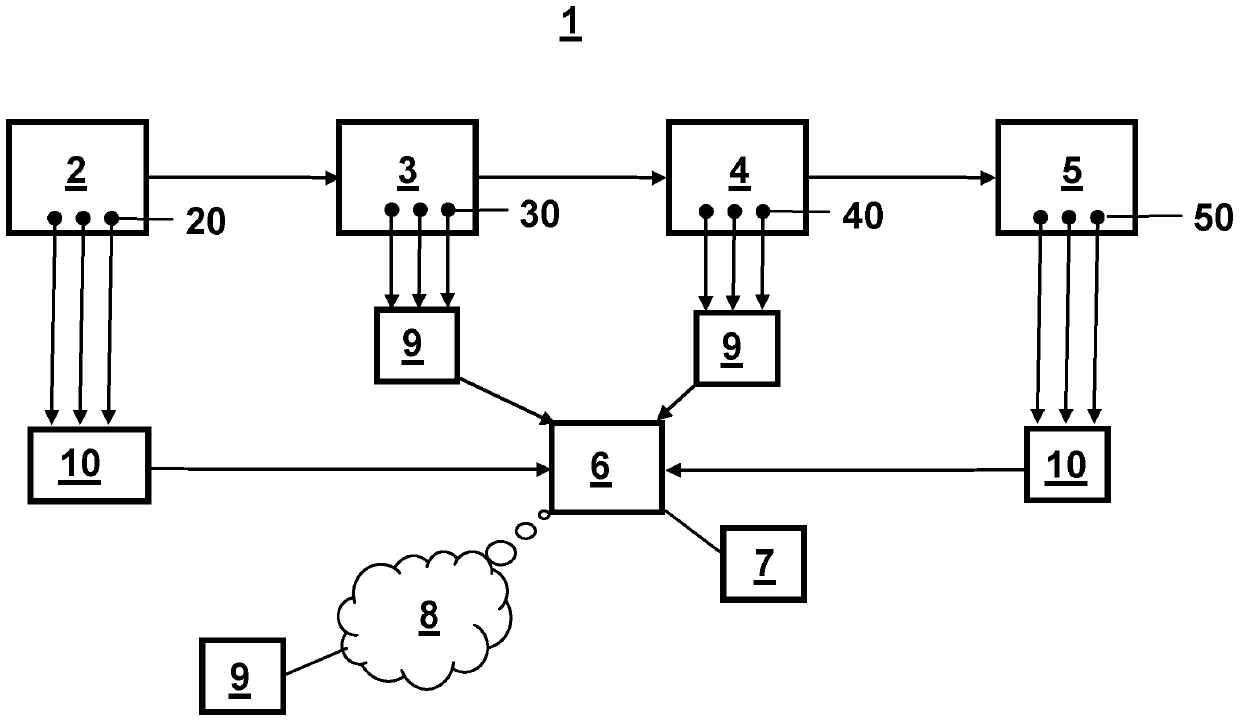

[0038] According to an embodiment of the present invention, refer to figure 1 , install the spinning line 1 at the spinning mill. The term "spinning mill" refers to an industrial plant in which the weaving process is carried out, consisting in the sequence of operations necessary to transform textile fibers, such as cotton, into yarns or threads. Preferably, a plurality of spinning lines 1 are installed in a spinning mill. The invention also relates to spinning preparation machines (eg drawframes, coilers, combers or rovings).

[0039] figure 1 The spun yarn 1 in the spinning mill comprises, for example, one or more opening and cleaning machines 2 (such as pluckers, agitators, preparatory and fine openers, mixers), one or more carding machines installed at the spinning mill machine 3, one or more combining machines 4, one or more spinning machines 5 (such as ring, compact, rotor and air-jet spinning machines), and machines 2, 3 for detecting and / or collecting said , 4, 5 l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com