Air seeder press wheel and closing wheel force control

A closed-end, gauge wheel technology, used in planter parts, sowing planters, sowing, etc., can solve problems such as insufficient furrow depth, affecting the ability of germinated seeds to break through the soil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] All references cited herein are hereby incorporated by reference in their entirety. In the event of a conflict between a definition in the present disclosure and a definition in a cited reference, the present disclosure controls.

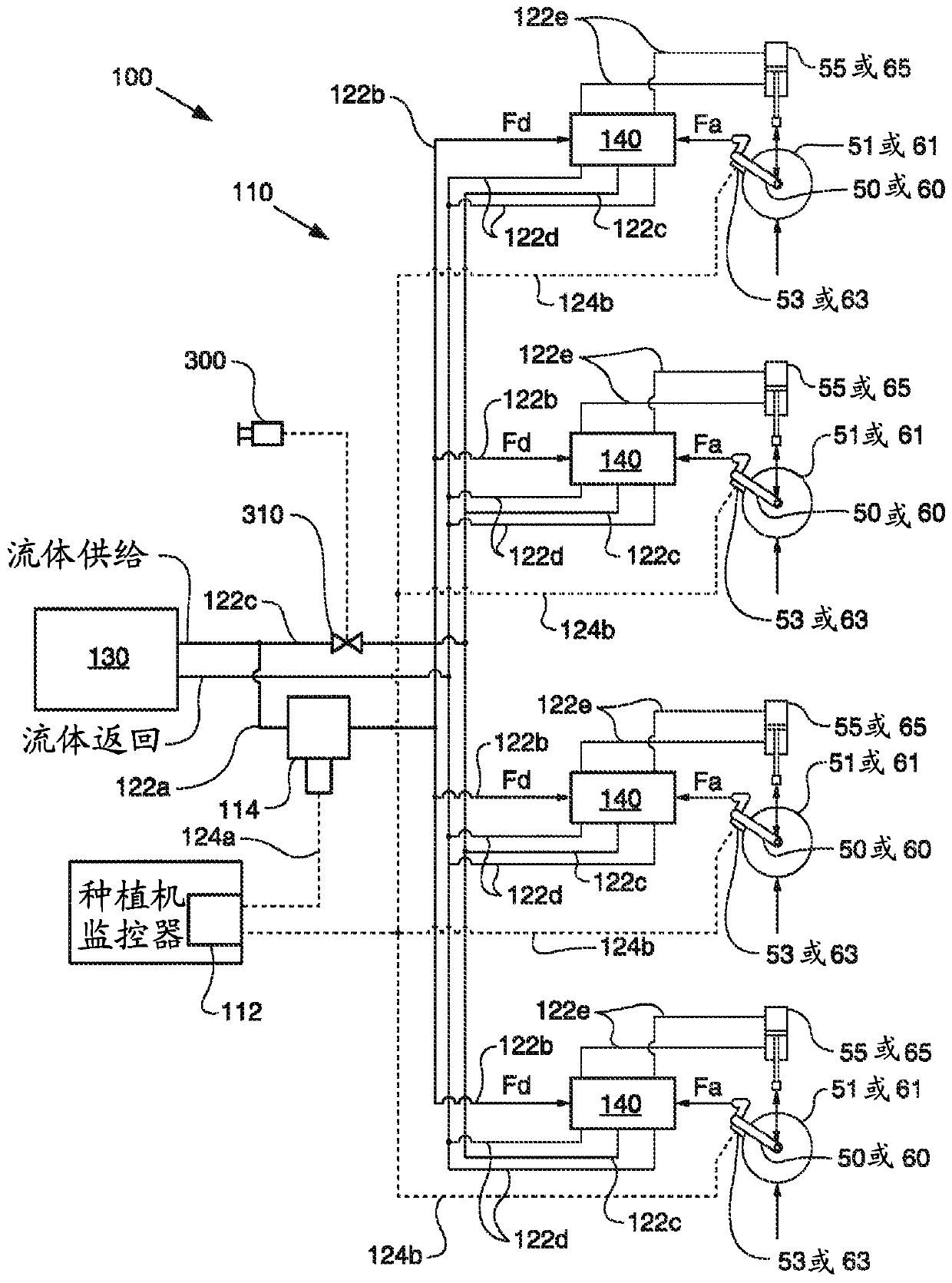

[0023] This article describes an apparatus for planting seeds, such as a pneumatic seeder.

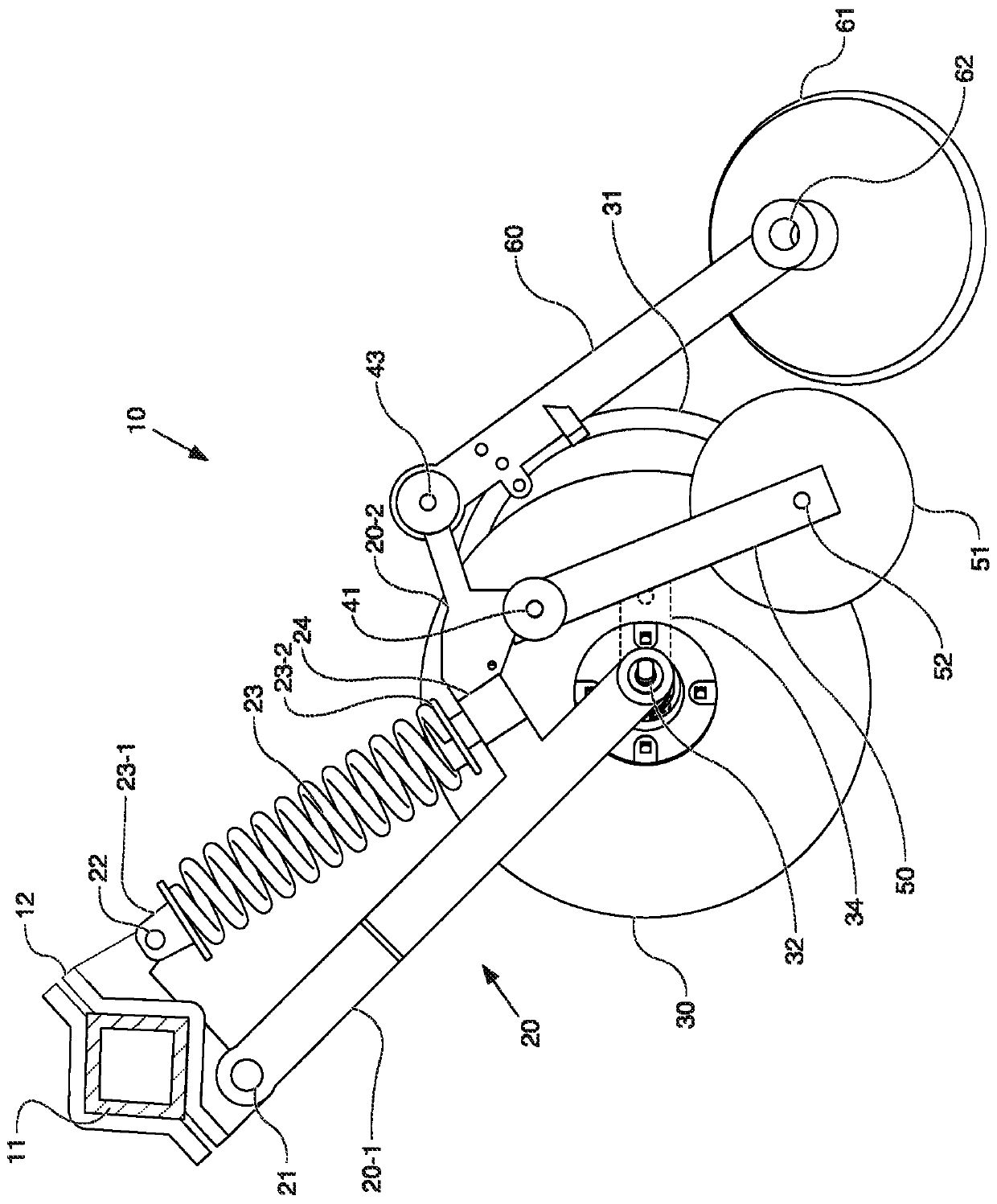

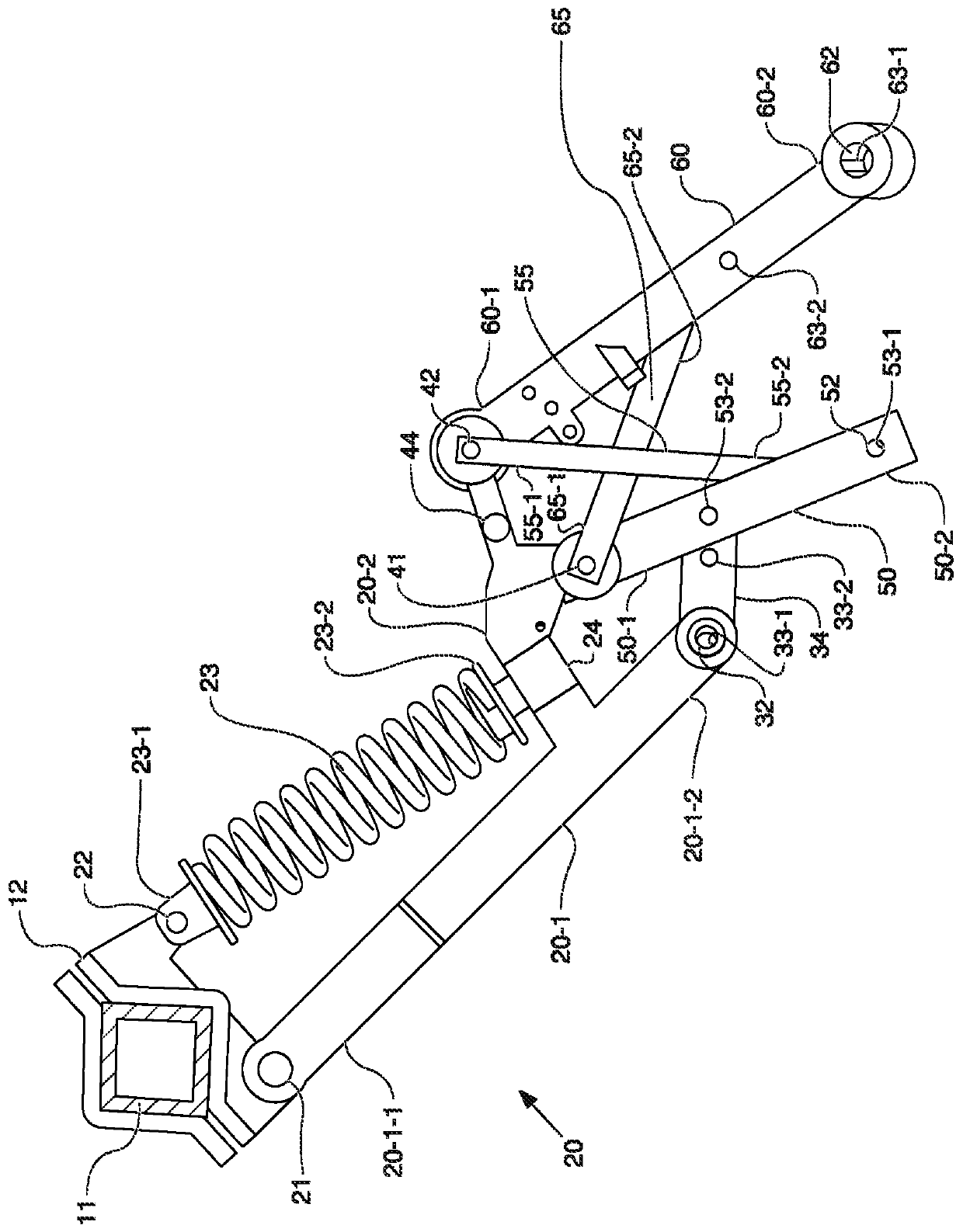

[0024] The arrangement unit of the pneumatic seeder of the prior art is shown in Fig. 1 . The sowing instrument 10 is mounted on the frame 11 via a bracket 12 . The support arm 20 is pivotally connected to the bracket 12 by a pivot 21 at a first end 20-1-1 of the support arm first portion 20-1. The support arm first part 20-1 is connected to a furrow disc 30 and a gauge wheel arm 34 at a second end 20-1-2 opposite the first end 20-1-1, for example by a shaft 32. The gauge wheel 31 is connected to a gauge wheel arm 34 opposite the shaft 32 . The second support arm part 20-2 branches from the first support arm part 20-1 and extends away from the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com