Method and system for establishing fracture forming limit diagram of high-strength aluminum alloy sheet

A technology of forming limit diagram and aluminum alloy plate, applied in the direction of applying stable tension/pressure to test material strength, etc., can solve the problem of loss of theoretical basis and validity of forming limit diagram

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

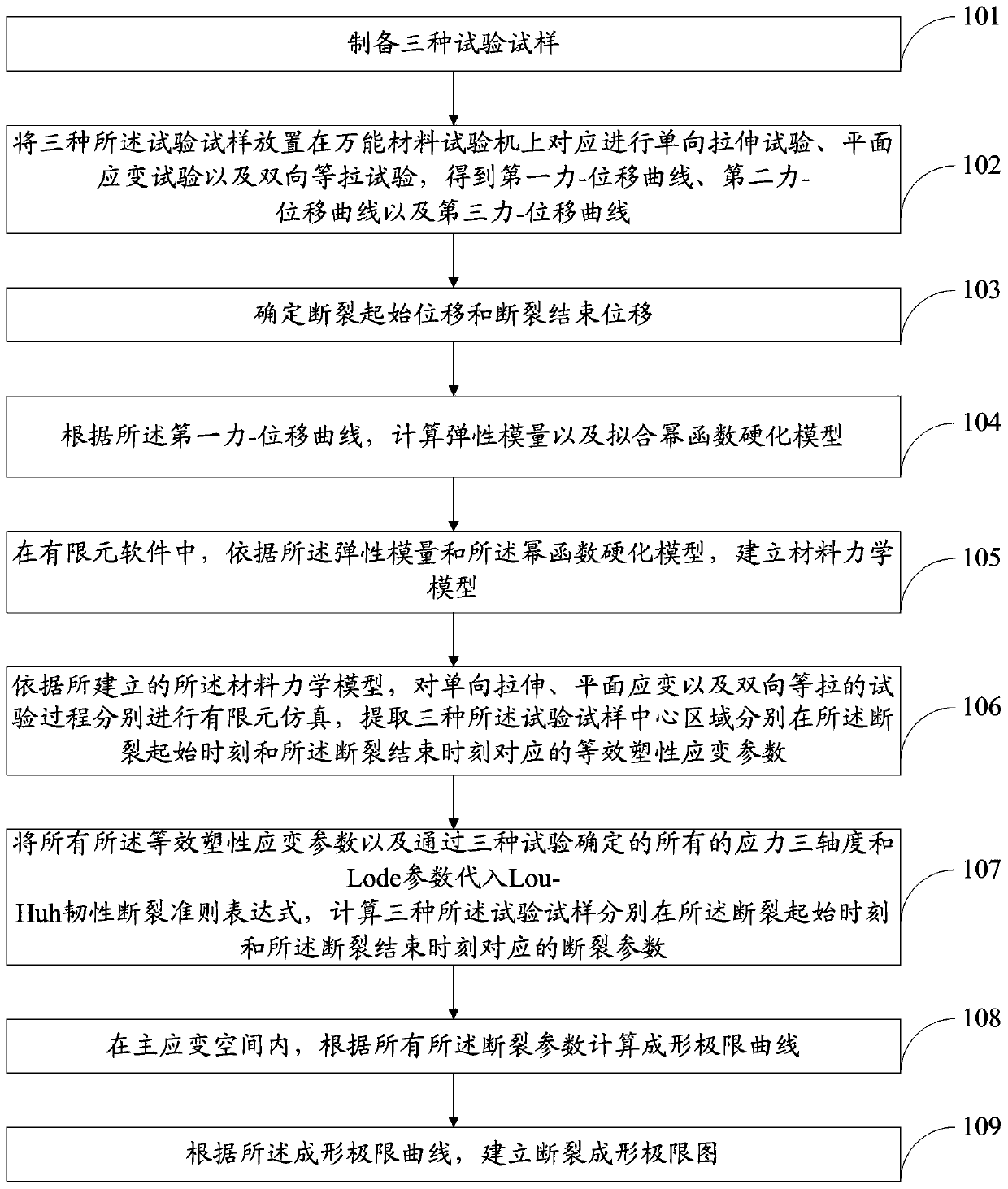

[0089] figure 1 It is a schematic flow chart of the method for establishing the fracture forming limit diagram of the high-strength aluminum alloy plate in the embodiment of the present invention, as shown in figure 1 As shown, the method for establishing the fracture forming limit diagram provided in Example 1 includes the following steps.

[0090] Step 101: Prepare three test samples; the test samples are respectively uniaxial tensile test samples, plane strain test samples and bidirectional iso-tensile test samples.

[0091] Step 102: Place the three kinds of test samples on the universal material testing machine to perform unidirectional tensile test, plane strain test and bidirectional isotensive test to obtain the first force-displacement curve, the second force-displacement curve and the second force-displacement curve. Three force-displacement curves; the first force-displacement curve is a curve obtained by placing the unidirectional tensile test sample on a universa...

Embodiment 2

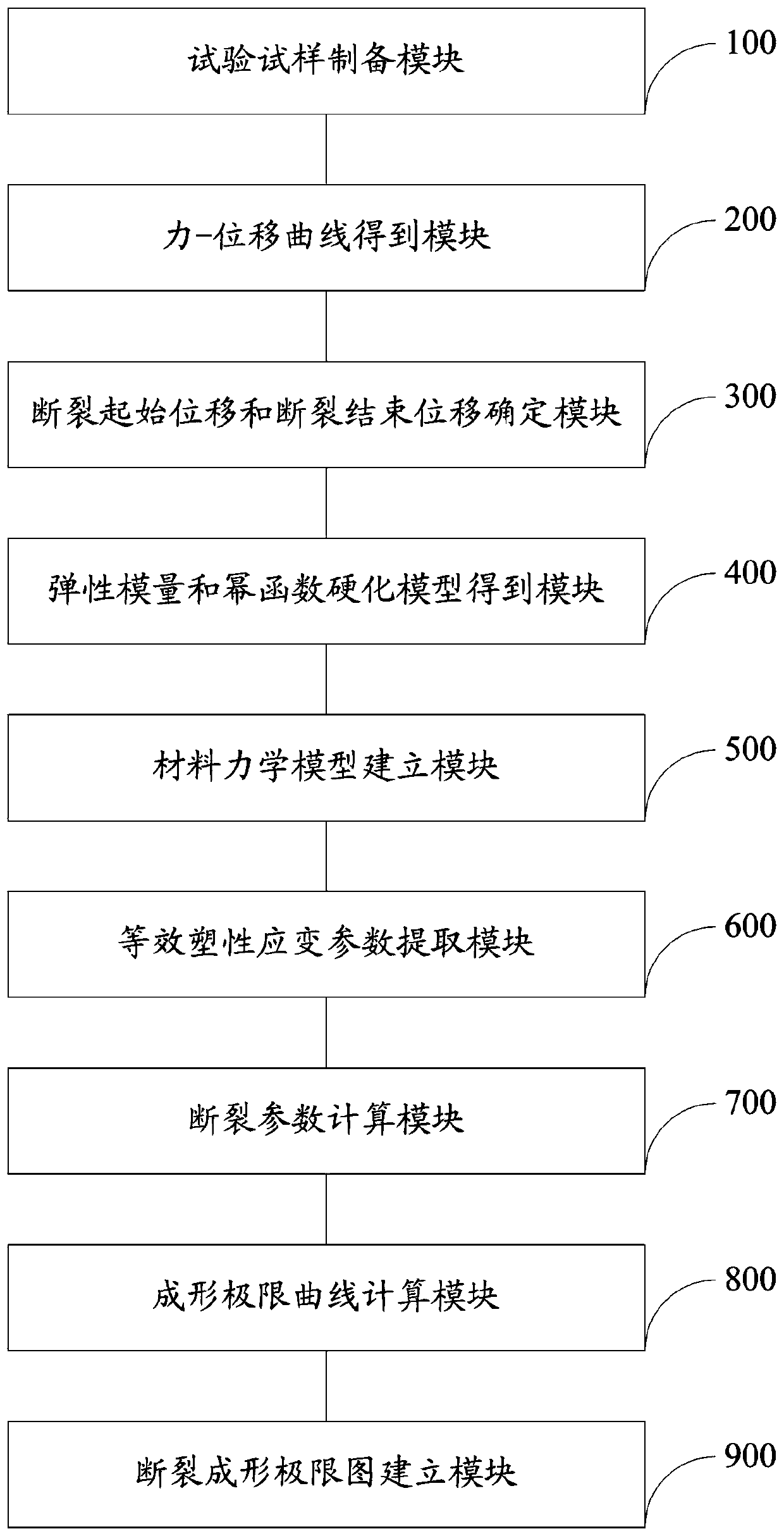

[0125] figure 2 A schematic structural diagram of the system for establishing the fracture forming limit diagram of the high-strength aluminum alloy plate in the embodiment of the present invention, as shown in figure 2 As shown, the fracture forming limit diagram establishment system provided by embodiment 2 includes:

[0126] The test sample preparation module 100 is used to prepare three kinds of test samples; the test samples are respectively uniaxial tensile test samples, plane strain test samples and bidirectional iso-tensile test samples.

[0127] The force-displacement curve obtaining module 200 is used to place the three kinds of test samples on a universal material testing machine to perform a unidirectional tensile test, a plane strain test and a two-way equal tension test to obtain the first force-displacement curve, the second Two force-displacement curves and the third force-displacement curve; the first force-displacement curve is a curve obtained by placing ...

Embodiment 3

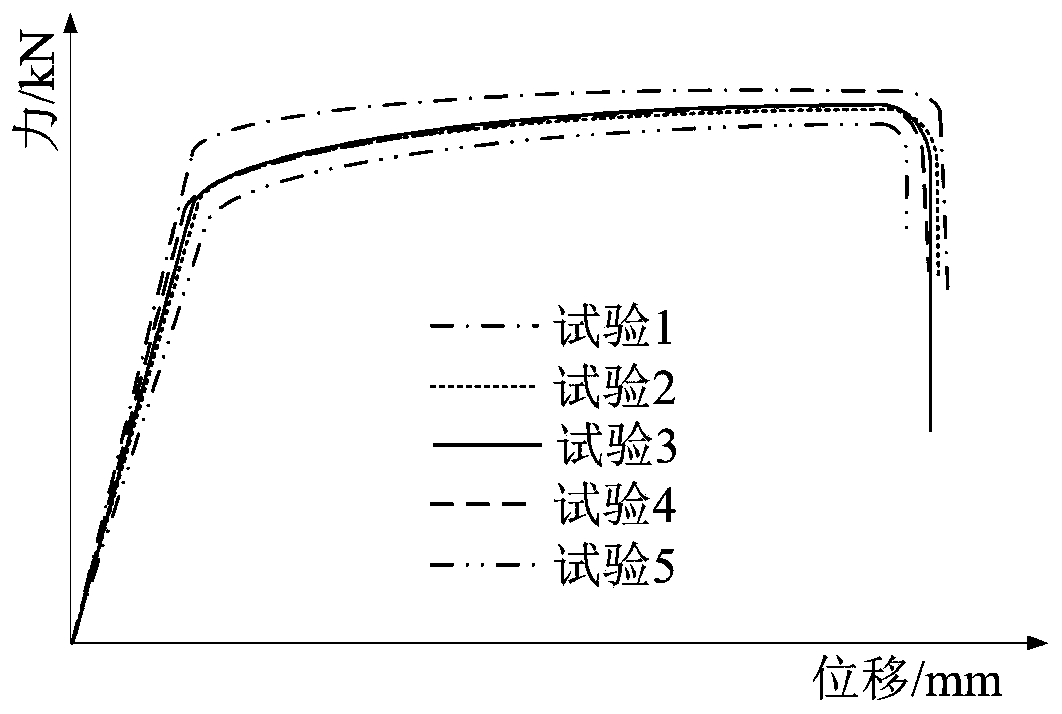

[0145] (1) Unidirectional tensile test

[0146] First, design the uniaxial tensile test specimen according to the national standard GB / T 228.1-2010, conduct the uniaxial tensile test on a universal material testing machine, and record the "force-displacement" curve during the test. Under the same test conditions, five sets of parallel tests were carried out, and a set of test data with better coincidence of the "force-displacement" curve was selected as the test result. According to this data, the "engineering stress-strain" curve of the test plate is obtained. Such as image 3 As shown, among the five groups of parallel experiments, the results of experiments 2, 3, and 4 are almost the same, while the results of experiments 1 and 5 are quite different compared with others, so one of experiments 2, 3, and 4 is selected as the test result. Then, on the "force-displacement" curve, select the displacement corresponding to the maximum force point as the fracture start displaceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com