Preparation process of low-salt chopped peppers

A preparation process and a technology of chopped peppers, applied in the field of chopped peppers preparation technology, can solve the problems of unguaranteed safety of fermented chopped peppers, lengthy pretreatment process, poor flavor and crispness, etc., and achieve rich and authentic flavor of pickled peppers and fermented taste Better, better crispness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

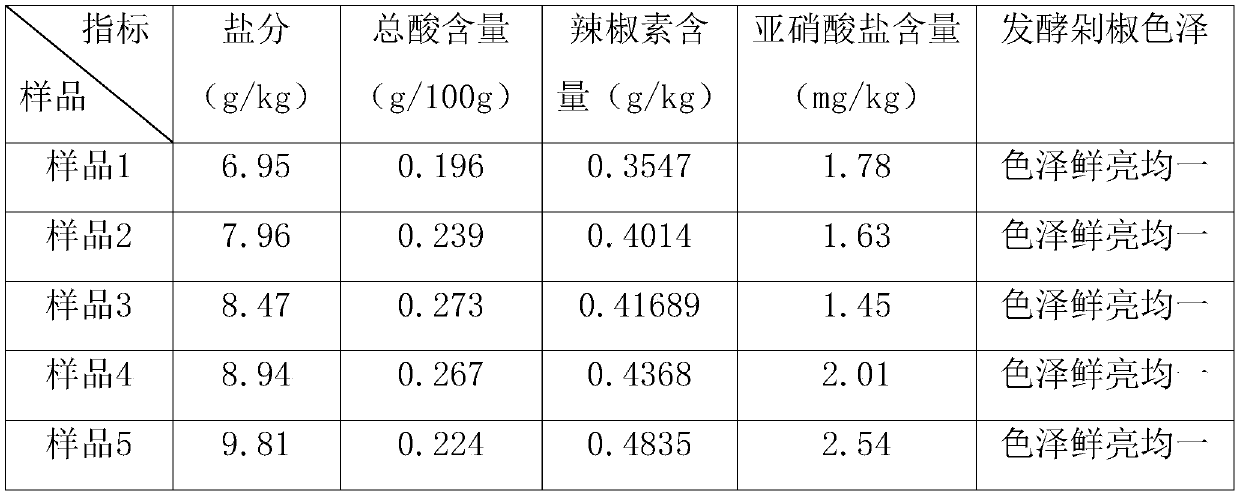

Examples

Embodiment 1

[0022] A preparation technology for low-salt chopped pepper, comprising the steps of:

[0023] 1) Pre-selection: select high-quality fresh peppers, remove the stems of the fresh peppers, wash them with pure water, and then dry the water on the surface of the fresh peppers naturally;

[0024] 2) Add the dried fresh peppers to the chopping machine and chop to obtain crushed peppers;

[0025] 3) According to the calculation in parts by mass, take 45 parts of crushed peppers and place them in a mixing container, then add 4 parts of white wine to the crushed peppers, then mix the crushed peppers and salt evenly and seal them for 1 hour;

[0026] 4) Add 7 parts of salt to the pulverized pepper obtained in step 3) and stir evenly, then add 30 parts of pure water to the pulverized pepper to dilute evenly and then seal and place;

[0027] 5) Dissolve 0.01 part of compound lactic acid bacteria powder in an appropriate amount of warm water at 30°C, then pour the compound lactic acid bac...

Embodiment 2

[0030] 1) Pre-selection: select high-quality fresh peppers, remove the stems of the fresh peppers, wash them with pure water, and then dry the water on the surface of the fresh peppers naturally;

[0031] 2) Add the dried fresh peppers to the chopping machine and chop to obtain crushed peppers;

[0032] 3) According to the calculation in parts by mass, take 50 parts of crushed peppers and place them in a mixing container, then add 5 parts of white wine to the crushed peppers, then mix the crushed peppers and salt evenly and seal them for 1.5 hours;

[0033] 4) Add 8 parts of salt to the pulverized pepper obtained in step 3) and stir evenly, then add 35 parts of pure water to the pulverized pepper to dilute evenly and then seal it;

[0034]5) Dissolve 0.02 part of compound lactic acid bacteria powder in an appropriate amount of warm water at 35°C, then pour the compound lactic acid bacteria solution into the pulverized pepper obtained in step 4) and mix evenly;

[0035] 6) Put...

Embodiment 3

[0037] A preparation technology for low-salt chopped pepper, comprising the steps of:

[0038] 1) Pre-selection: select high-quality fresh peppers, remove the stems of the fresh peppers, wash them with pure water, and then dry the water on the surface of the fresh peppers naturally;

[0039] 2) Add the dried fresh peppers to the chopping machine and chop to obtain crushed peppers;

[0040] 3) According to the calculation in parts by mass, take 52 parts of crushed peppers and place them in a mixing container, then add 5.5 parts of white wine to the crushed peppers, then mix the crushed peppers and salt evenly and seal them for 1.5 hours;

[0041] 4) Add 8.5 parts of salt to the pulverized pepper obtained in step 3) and stir evenly, and then add 40 parts of pure water to the pulverized pepper for uniform dilution and then seal and place;

[0042] 5) Dissolve 0.02 part of compound lactic acid bacteria powder in an appropriate amount of warm water at 35°C, then pour the compound ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com