High-frequency test bench for QFN chip

A technology of test socket and chip, which is applied in the direction of electronic circuit testing, measuring electricity, measuring devices, etc., and can solve the problems of long channel, low quality of high-frequency signal transmission, high probe inductive reactance, capacitive reactance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

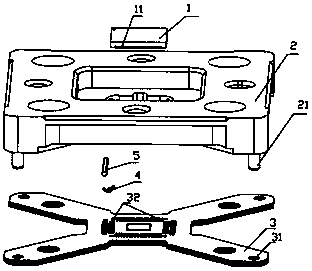

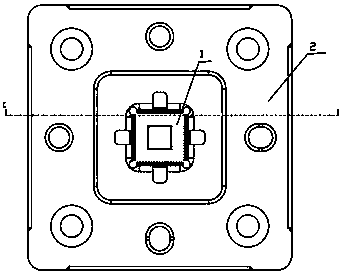

[0018] The technical scheme of the present invention is specifically described below in conjunction with the embodiments. The present invention discloses a high-frequency test socket for a QFN chip. Figure 1-Figure 4 As shown, it includes at least two layers of test main boards 3 superimposed on each other, and a guide plate 2 arranged above the test main board 3. In the present invention, there are four test main boards 3, and adjacent test main boards 3 are glued together. Knots connect to form a whole. The test main board 3 is provided with four ends, and each end is provided with a socket hole 31 .

[0019] The guide platen 2 is made of polyamide-imide material, and a guide column 21 is provided at the bottom, and the guide platen 2 and the test main board 3 are plugged and connected through the guide column 21 . The cross-section of the test main board 3 in the present invention is in the shape of "x", the middle part of the test main board 3 is a detection part, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com