Systems for controlled liquid food or beverage product creation

A liquid product, liquid technology, used in beverage preparation devices, food science, frozen desserts, etc., can solve problems such as excessive dilution, inconsistent user experience, and non-automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

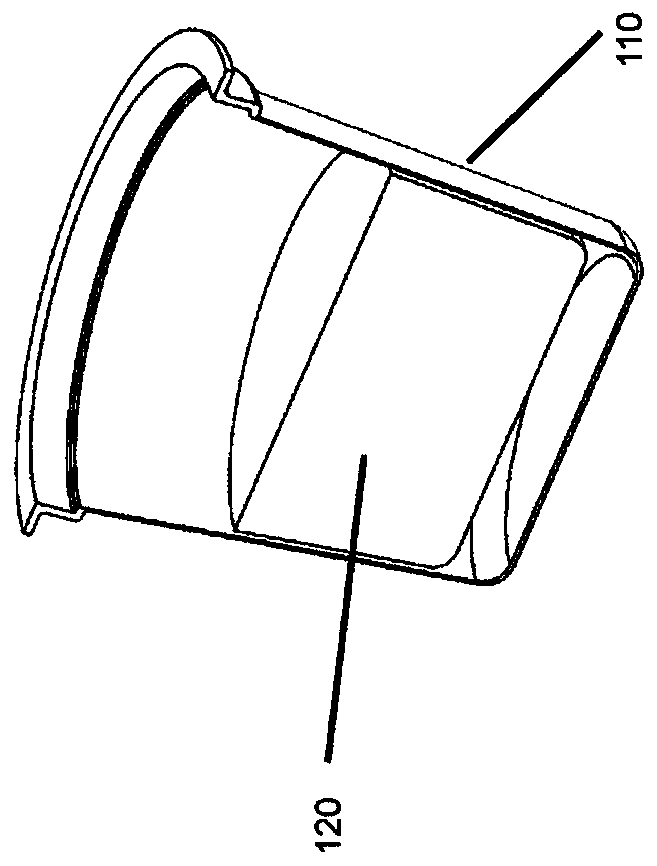

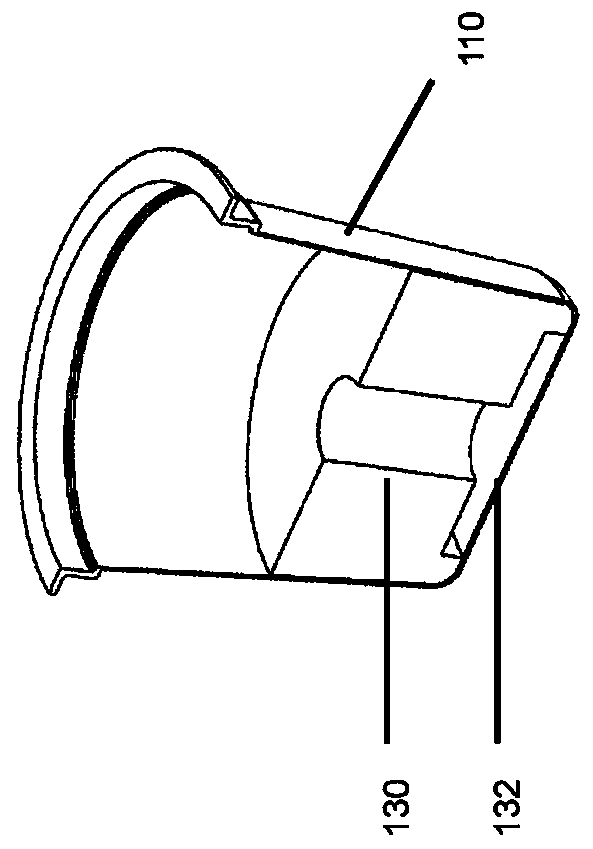

[0678] Example 1 shows the range of coffee extract strengths (TDS) that can be used to successfully create a SCAA gold standard beverage. In this example, a filterless single chamber mixing vessel contains frozen liquid contents. The container has as Figure 32 The profile shown in , includes a height of about 1.72 inches, a top ID of about 1.80 inches, a draft angle of about 5 degrees, and a bottom ID of about 1.45 inches. The top of the container is sealed with a pierceable layer, and the end layer can be pierced (eg, through a dispenser / brewer needle, injecting, but not limited to, the needles described above). The frozen liquid coffee extract is in contact with substantially the entire end layer and a portion of the sidewall.

[0679] To produce a final coffee beverage product with a TDS of about 1.15% to about 1.35% (with an optional target of 1.25% TDS, the center point of the SCAA Gold Cup standard), 8 ounces of 195°F water is used to melt and dilute the 15°F frozen l...

example 2

[0686] Example 2 shows the range of coffee extract strengths (TDS) that can be used to successfully make espresso beverages. In this example, a filterless single chamber mixing vessel contains frozen liquid contents. The outline and dimensions of the container are also related to the Figure 32 same as described in . In this example, the frozen liquid content, again espresso extract, is in contact with substantially the entire end layer and a portion of the side wall.

[0687] To produce a final espresso beverage product with a TDS of about 9.15% to about 9.35% (with an optional target of about 9.25% TDS), the 15°F frozen liquid contents are thawed and diluted with sufficient 195°F water to yield 4 The dispensed volume in ounces, sometimes described as a double espresso. Table 3 shows several alternative implementations of the frozen liquid content of this example, and the effect on various parameters of varying the amount of frozen liquid content and the concentration of t...

example 3

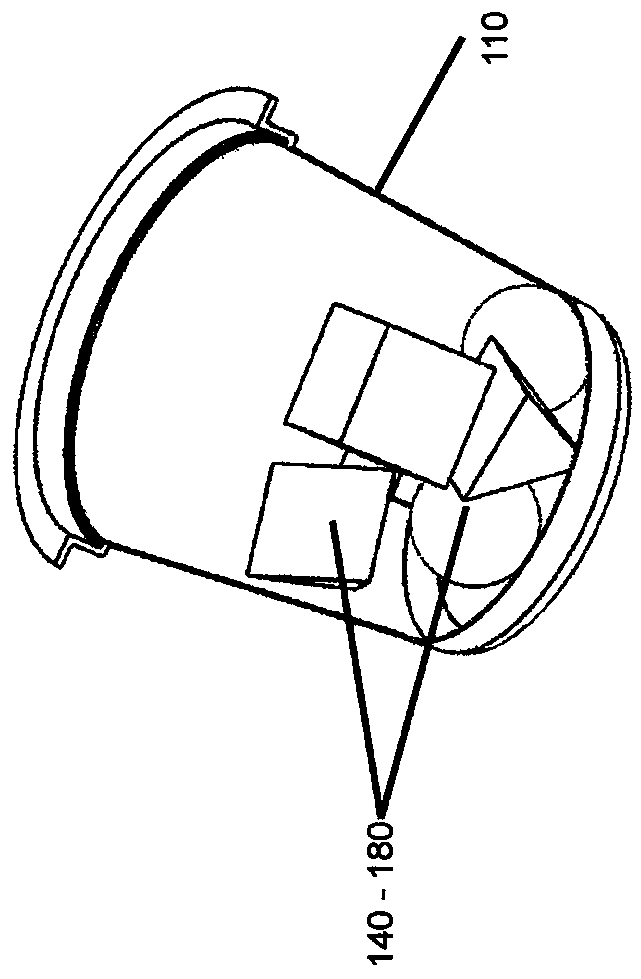

[0692] Example 3 shows the range of options available when two or more container sizes can be accommodated in a single dispenser. In this example, the dispenser is designed to accommodate at least two containers of different capacities and shapes, each container providing at least two types of finished product. The volume of the first container is smaller than that of the second container. Both containers have the same top diameter, but differ in their depth. Containers with lower volumetric capacity are shorter in height and have a larger base diameter than higher capacity containers. Containers with greater volumetric capacity have non-linear side walls (eg, concave, stepped, etc.). Lower capacity containers have a capacity of 1 ounce and have such Figure 67A to B (the second step to the receiver only), while higher-capacity containers hold 2.25 ounces and have such Figure 69A to the shape shown in B. Both sizes of these containers are equipped with visual markings th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com