Seedling falling device applicable to bottomless seedling tray and seedling taking machine

A technology for dropping seedlings and seedling trays is applied in the field of seedling dropping devices and seedling picking machines, which can solve the problems of high labor intensity, low transplanting efficiency, unstable quality, etc., so as to save costs, reduce labor intensity, and avoid impossible off-disk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

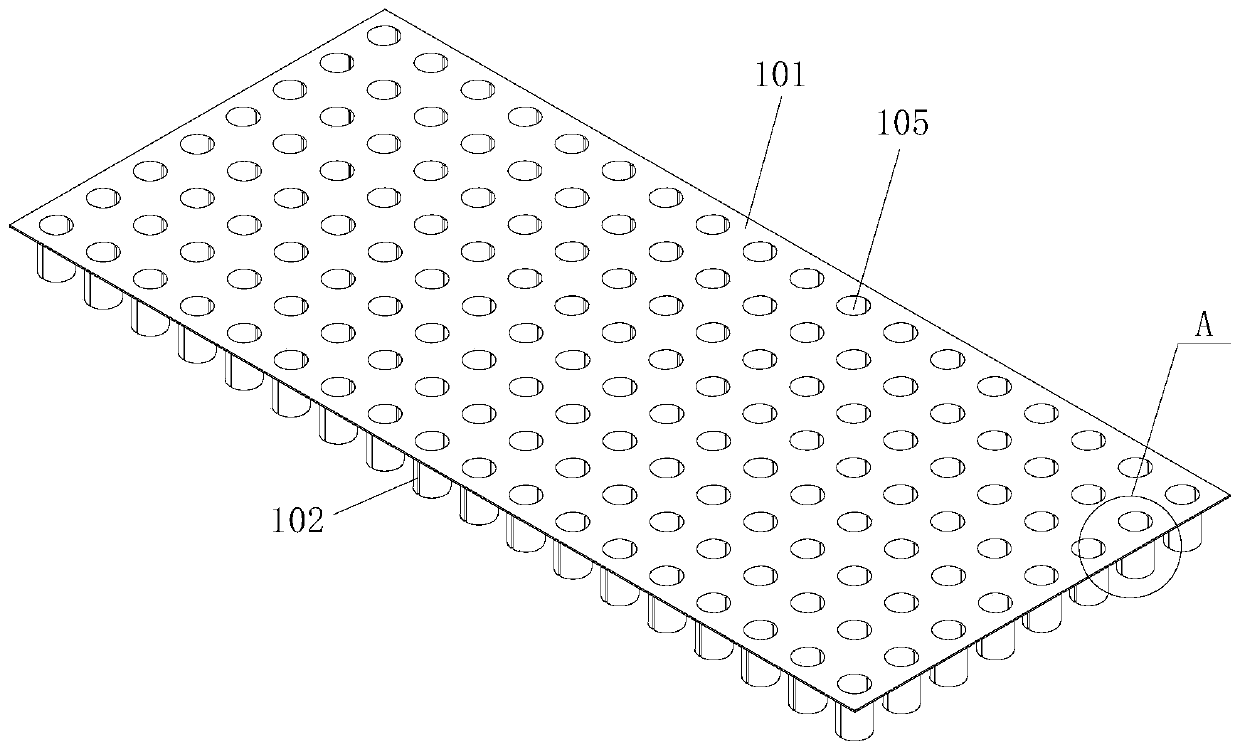

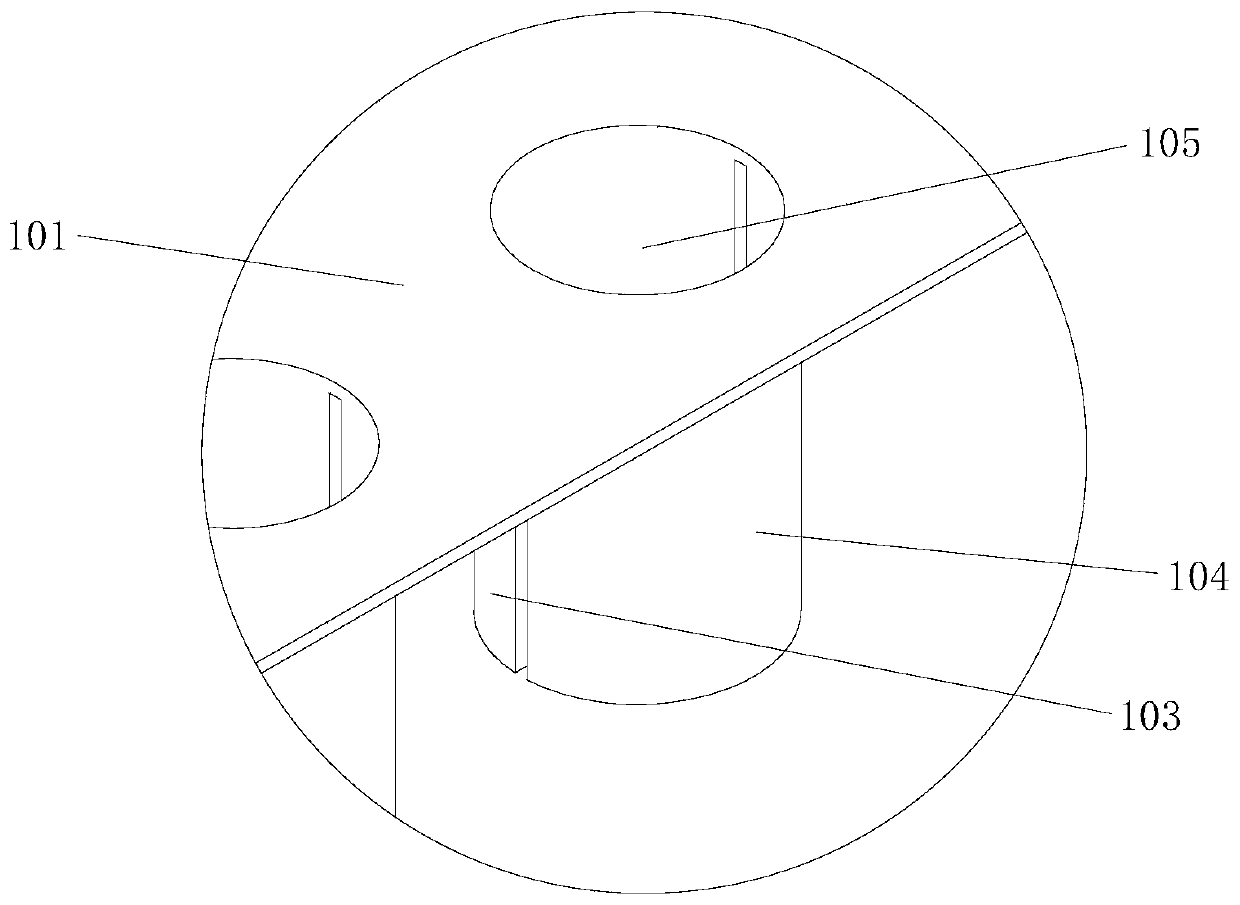

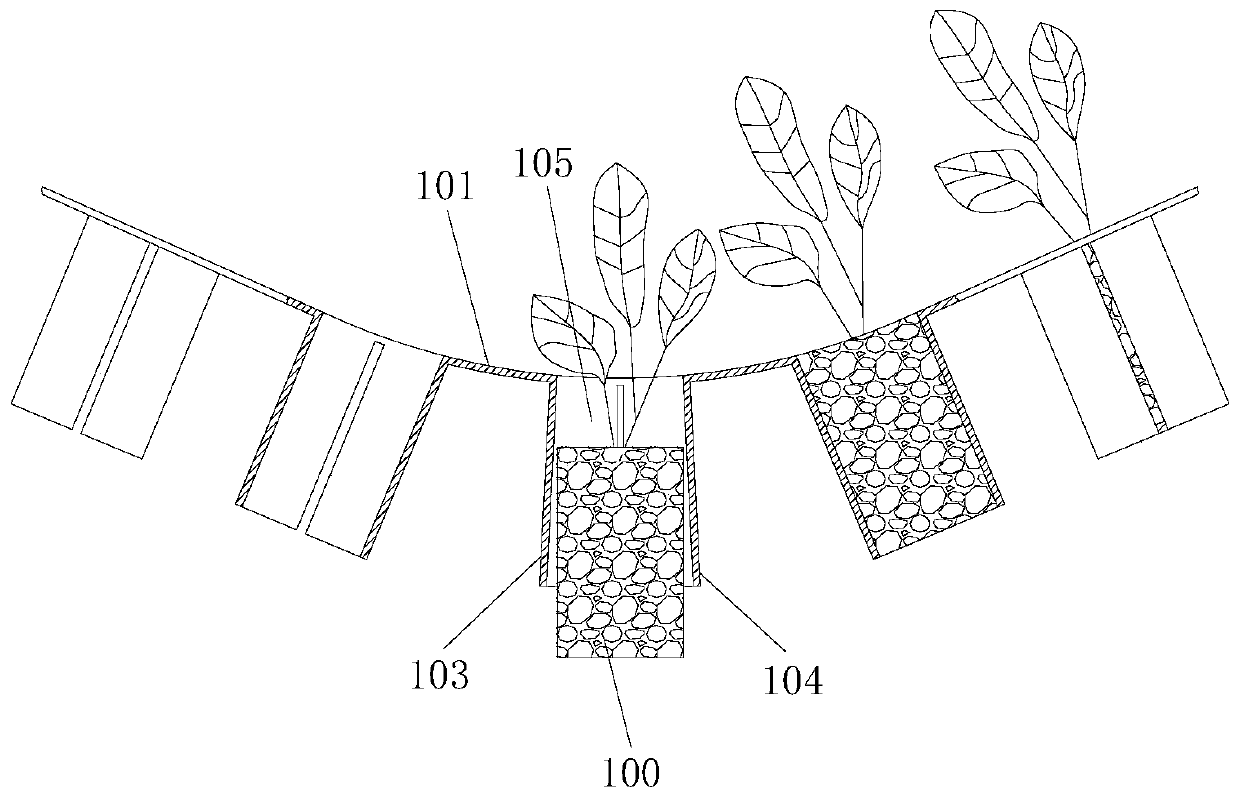

[0033] Such as Figure 11 As shown, the seedling dropping device applicable to the bottomless seedling tray of the present embodiment includes a support 41 on which a synchronous ejection assembly 42 for simultaneously ejecting more than two potted seedlings 100 in the bottomless seedling tray and The synchronous seedling dropping component 43 for supporting two or more potted seedlings 100 at the same time, the synchronous seedling dropping component 43 is located below the synchronous ejecting component 42 . The synchronous ejection assembly 42 of the seedling dropping device suitable for the bottomless seedling tray can eject the pot seedlings 100 in more than two pot bodies 102 at the same time, so as to realize the forced removal of the pot seedlings 100 and prevent the pot seedlings 100 from being unable to come off the tray. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com