Reciprocating forced cake-unloading mechanism and method for filter cloth

A filter cloth and filter cake technology, applied in the field of filter press filter cloth unloading mechanism and method manufacturing, can solve the problems of high manufacturing cost, inability to realize automatic forced unloading of cake, complicated filter cloth walking mechanism, etc., to ensure cleanliness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

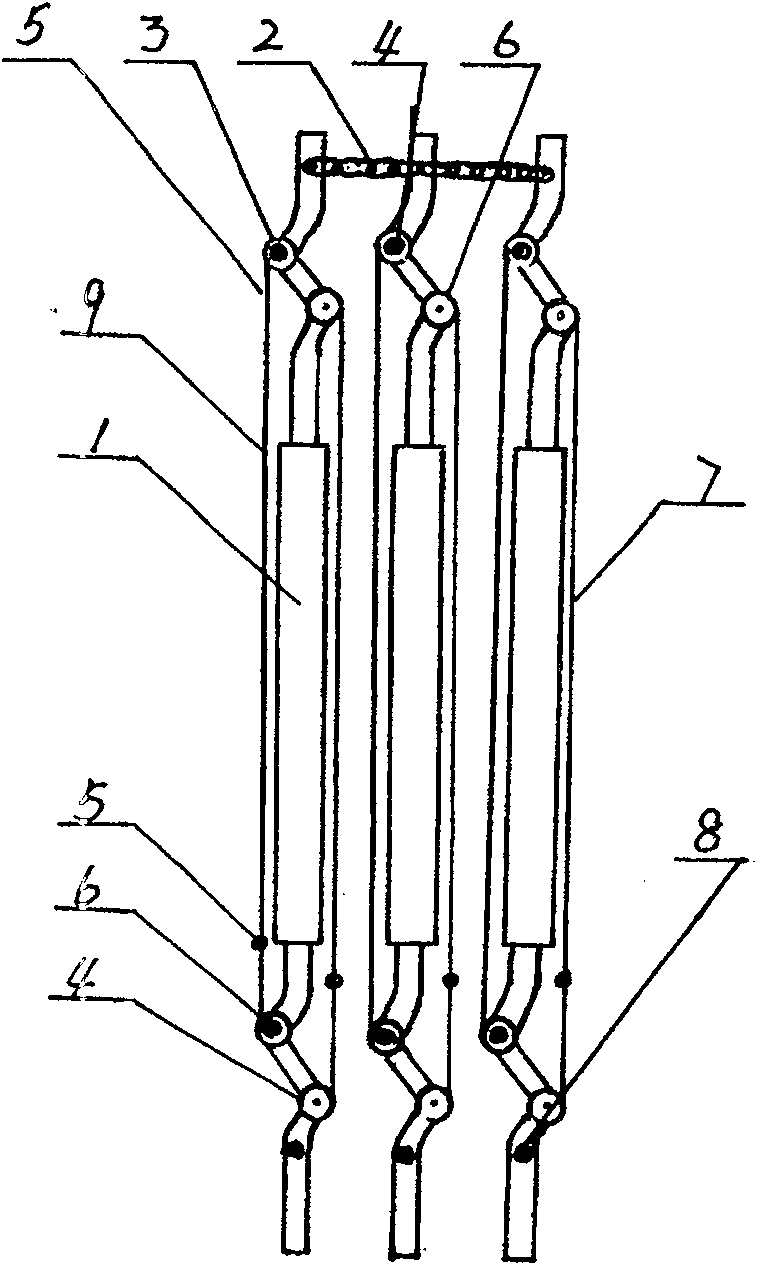

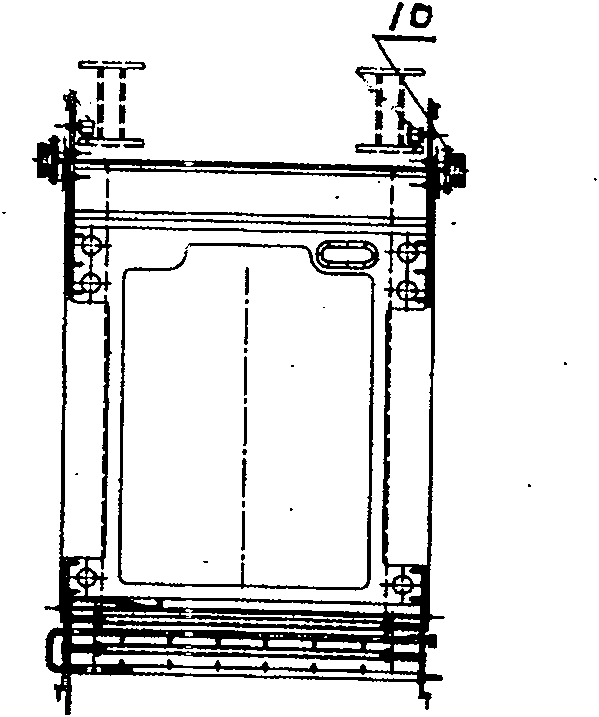

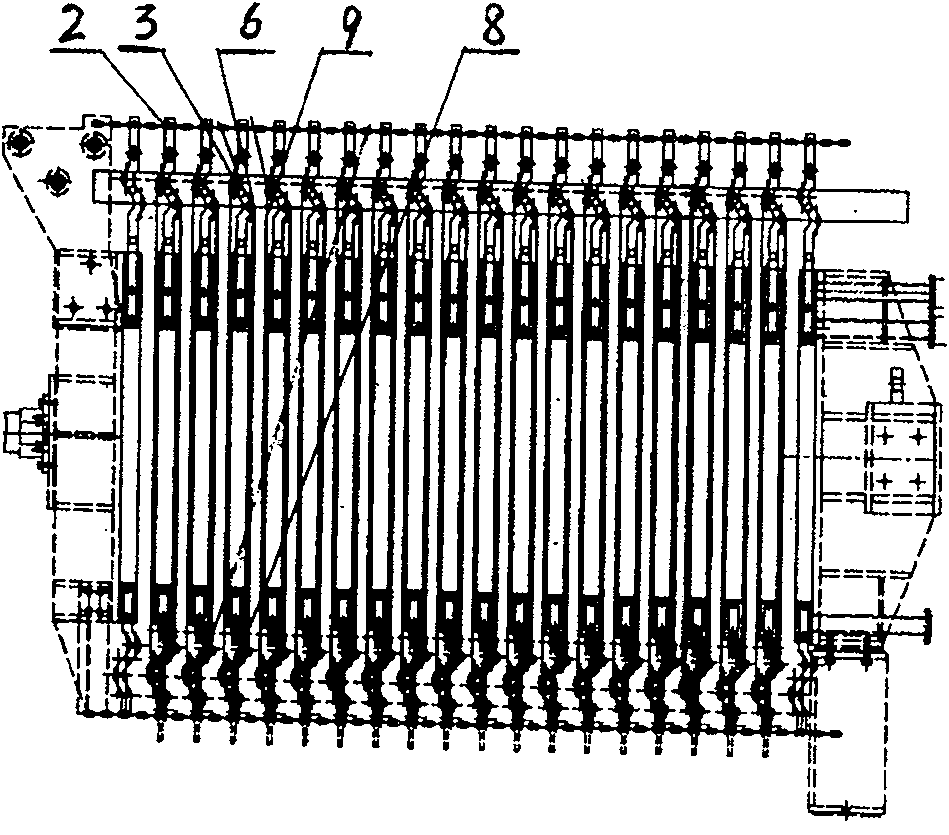

[0011] Embodiment 1: with reference to attached Figure 1~3 . The filter cloth reciprocating forced unloading mechanism, the adjacent diaphragm filter plates in the multiple diaphragm filter plates 1 located between the thrust plate and the pressing plate are connected by a circular chain 2 and driven by the pressing plate to drive multiple diaphragms The filter plate is opened or closed, the upper and lower ends of the multi-diaphragm filter plates are respectively pierced with upper and lower suspenders 4, the ends of the upper and lower suspenders 4 are equipped with sprockets 3, and the upper and lower suspenders 4 It rotates around its shaft hole or is sleeved with bearings, and the bearings are located in the lug bearing holes at the upper and lower ends of a plurality of diaphragm filter plates 1 . The upper and lower rollers 6 are respectively located on and above the upper and lower sprockets 3 and are not on the same axis. The purpose is to ensure the reliable opera...

Embodiment 2

[0012] Embodiment 2: On the basis of Embodiment 1, the filter cloth is reciprocally forced to unload the cake method, and the multiple interconnected diaphragm filter plates located between the thrust plate and the compression plate are driven by the compression plate to drive the plurality of diaphragm filters. The plates are opened one by one, and the filter cloths located on the upper and lower filter cloth rods and the diaphragm filter cloth run synchronously downwards under the drive of the moving beam and the chain wheel and chain transmission mechanism through their respective filter cloth rods. When the filter cake on the filter cloth goes down and the diaphragm When the filter plate is down, because the diaphragm filter cloth is affected by the running angle of the chain, it runs obliquely with the filter cake at an angle, and is forcibly separated from the filter cake on the diaphragm filter cloth and removed, and then the diaphragm filter cloth located on multiple dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com