Forced pan unloading mechanism for rotary filter cloth and forced pan unloading method

A filter cloth and filter cake technology, which is applied in the field of filter cloth cake unloading mechanism and method of filter press, can solve the problems of high manufacturing cost, inability to realize automatic forced cake unloading, complicated filter cloth walking mechanism, etc., to ensure cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

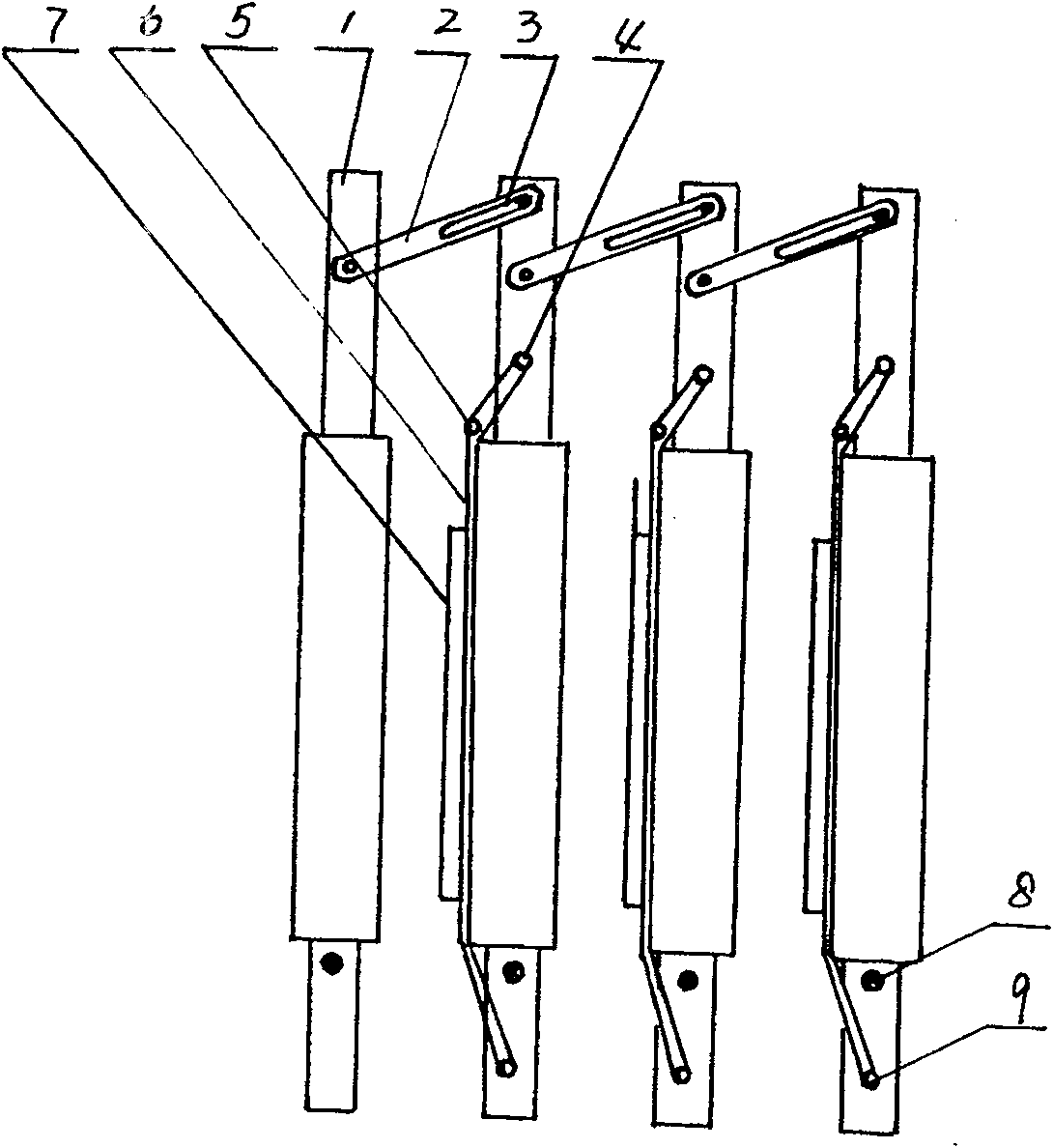

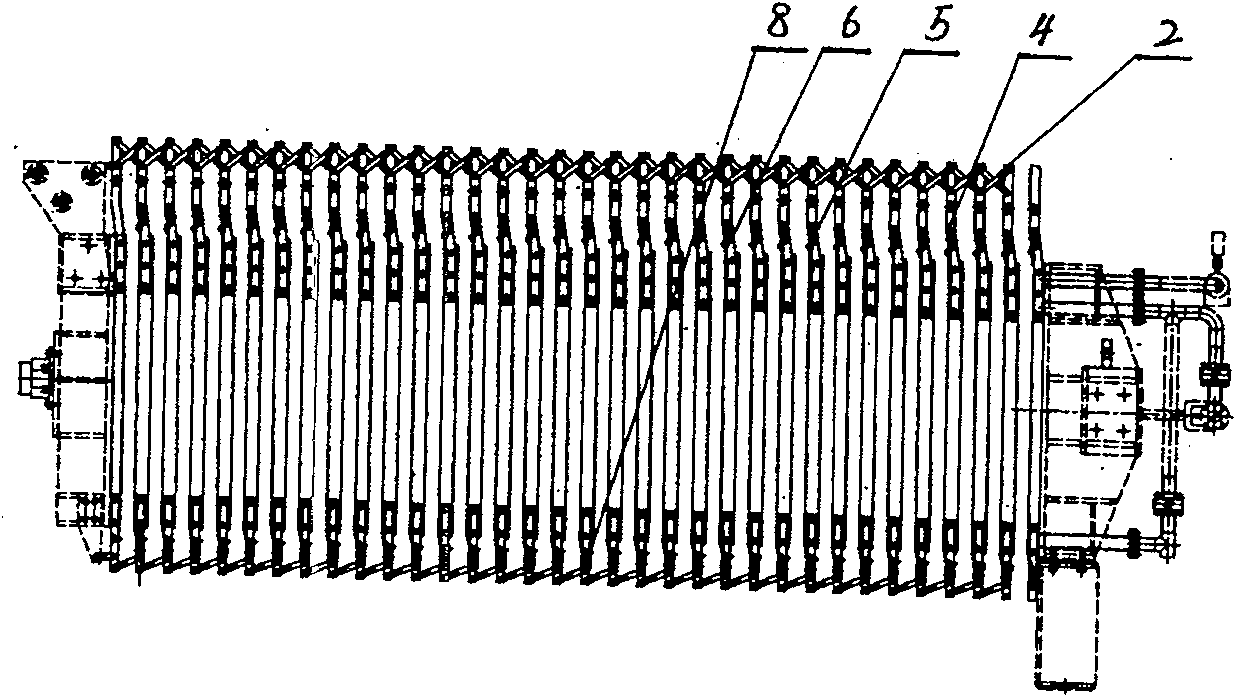

[0012] Embodiment 1: with reference to attached Figure 1~3 . Filter cloth rotating forced cake unloading mechanism, the adjacent diaphragm filter plates in the multiple diaphragm filter plates 1 located between the thrust plate and the pressing plate are connected by the guide groove pin plate 2, and the two ends of the guide groove pin plate 2 are pin holes 10 and a pin hole is communicated with guide groove 3, and the structure that connects is prior art, as electric sliding door structure. The plurality of diaphragm filter plates 1 are driven by the pressing plate to open or close the plurality of diaphragm filter plates, and the upper and lower end lugs of the plurality of diaphragm filter plates 1 are respectively pierced with an upper suspension rod 4 and a lower suspension rod 9 (also Be exactly bar), upper and lower suspenders 4 and 9 rotate around their shaft holes or are sleeved with bearings and the bearings are located in the upper and lower end lug bearing holes...

Embodiment 2

[0013] Embodiment 2: On the basis of Embodiment 1, the filter cloth is rotated and forced to unload the cake method, and the multiple interconnected diaphragm filter plates located between the thrust plate and the compression plate are driven by the compression plate to drive the plurality of diaphragm filter plates. The plates are opened one by one, and the multiple membrane filter cloths located on the surface of the multiple membrane filter plates are respectively driven by the moving beam through their respective filter cloth guide rods. Due to the installation angle of the lower boom, the diaphragm filter cloth runs obliquely with the filter cake at an angle, and the filter cake on the diaphragm filter cloth is forcibly removed, and then the filter cloth in the diaphragm filter cloth on multiple diaphragm filter plates The guide rods are driven synchronously by the moving beam, and each filter cloth guide rod drives the diaphragm filter cloth to run upward synchronously. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com