A Two-Phase Flow Constant Ratio Mixing Valve

A technology of mixed transmission and spool, applied in the field of refining and chemical industry, can solve the problem of unstable mixing ratio of two-phase flow and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

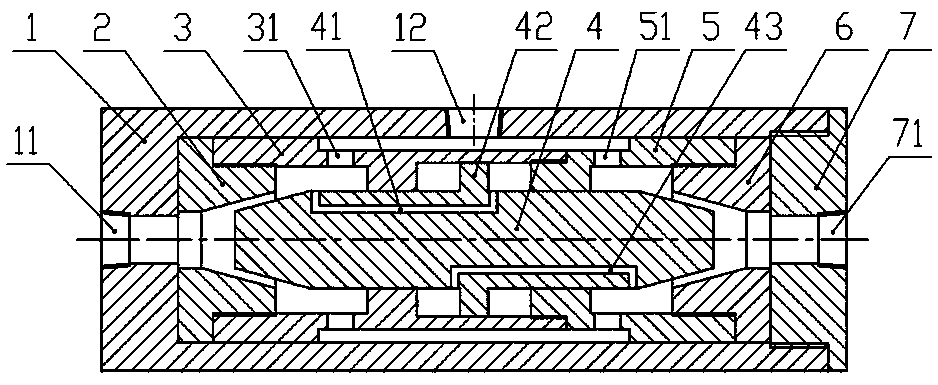

[0009] Such as figure 1 As shown, a two-phase flow fixed-ratio mixing valve of the present invention is composed of an outer shell 1, a taper sleeve a2, an inner cylinder a3, a valve core 4, an inner cylinder b5, a taper sleeve b6 and a cover 7. Its structural features are: the inner cavity of the outer casing 1 is set as a counterbore, the left end of the outer casing 1 is provided with an inlet hole a11, and the middle part of the outer casing 1 is provided with a mixing hole 12; the right end of the outer casing 1 is connected with the cover 7 with screws, and the sealing An inlet hole b71 is set in the middle of the cover 7; the inner cavity of the tapered sleeve a2 is set as a conical hole, and the inner cavity of the tapered sleeve b6 is set as a conical hole; Steps are raised, four outflow holes a31 are evenly arranged in the left circumferential direction of the raised step in the middle of the inner cavity of the inner cylinder a3; Four outflow holes b51 are evenly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com