A kind of temperature and humidity sensor self-checking method

A temperature and humidity sensor, temperature and humidity technology, used in instruments and other directions to prevent false alarms, improve service life and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to enable those skilled in the art to understand the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

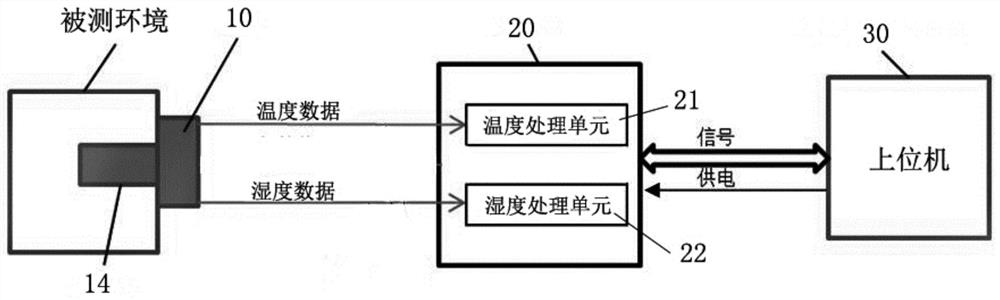

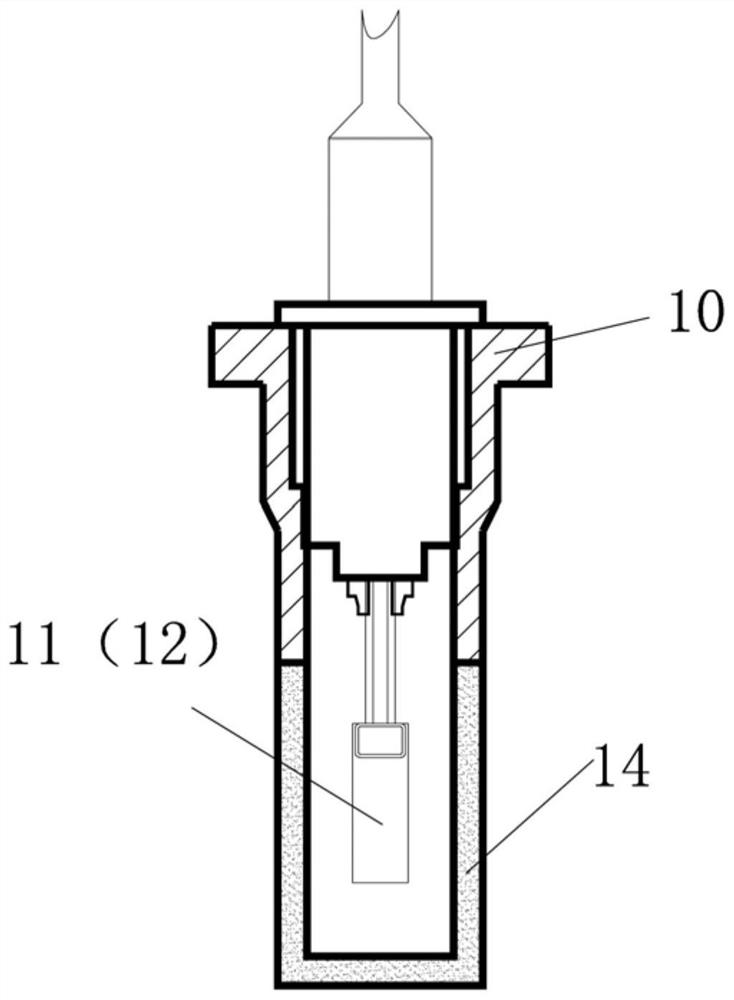

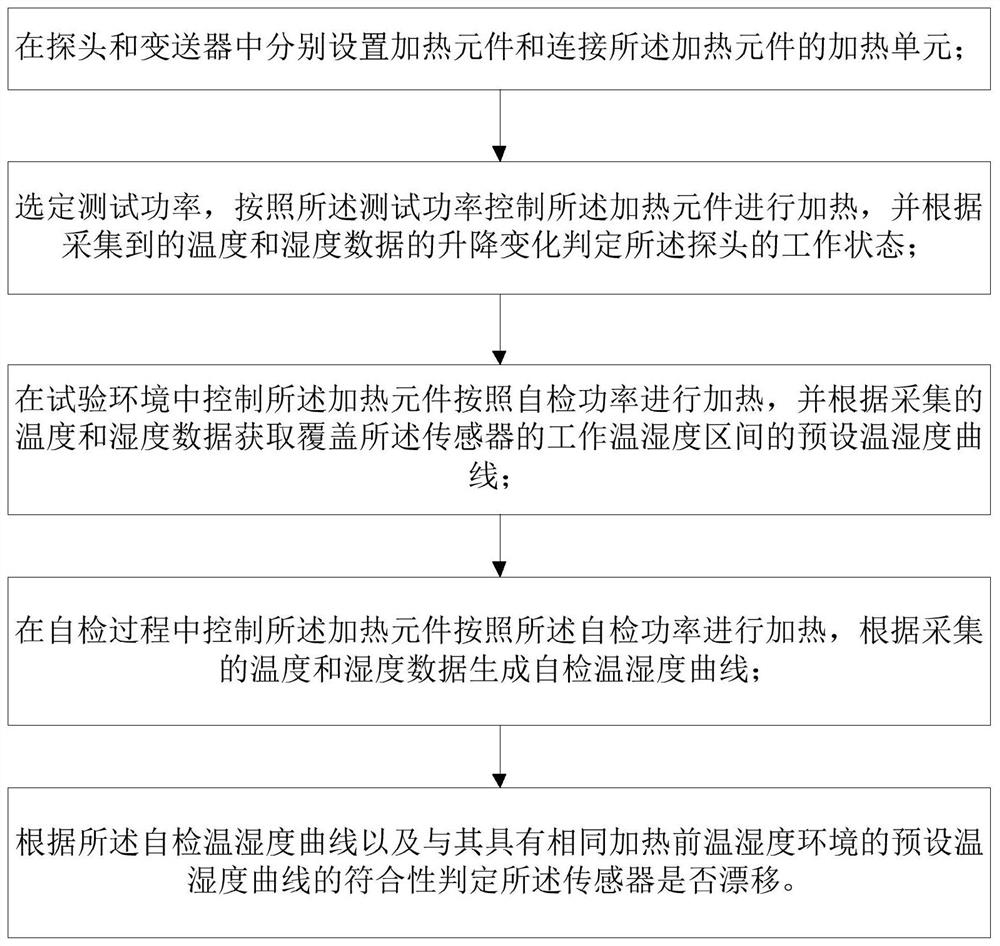

[0051] In order to solve the problem that the existing technology cannot judge and detect the real state and specific performance of the temperature and humidity sensor, the present invention aims to provide a self-checking method for the temperature and humidity sensor. Element, add a heating unit to the transmitter, when self-test is required, the space inside the probe filter will be heated after the heating unit controls the heating element to heat up, the environment in the filter will be affected, causing the temperature to rise and the humidity to drop . Therefore, it is possible to compare the temperature and humidity data collected after heating with the data before the self-test, and analyze whether the change value conforms to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com