Method for forming piston of rubber air spring

A rubber air spring and molding method technology, applied in the field of metal parts molding, can solve the problems of difficult to ensure smooth transition, difficult piston molding, large diameter difference, etc., to achieve the effect of improving efficiency and accuracy, improving molding accuracy, and facilitating molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

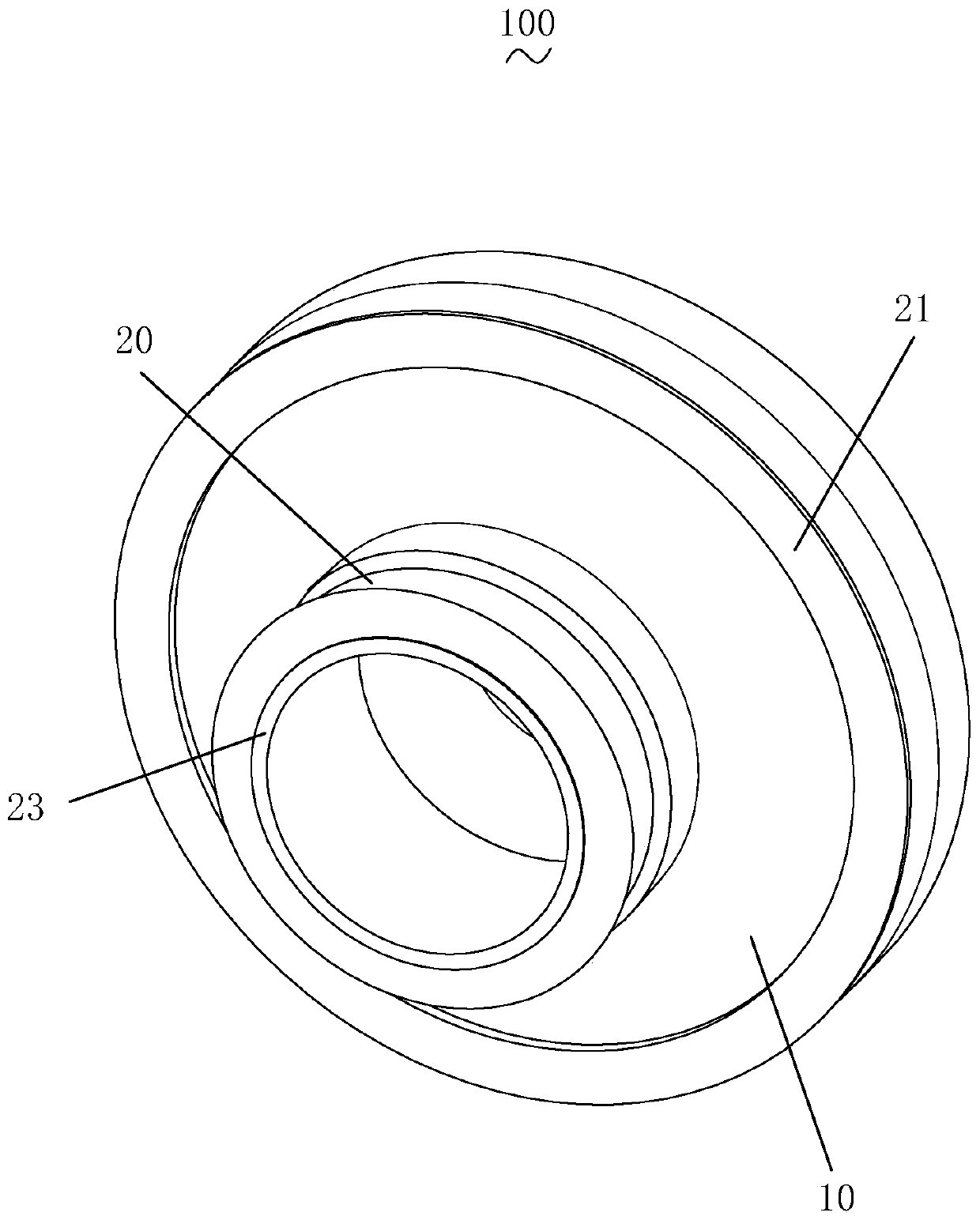

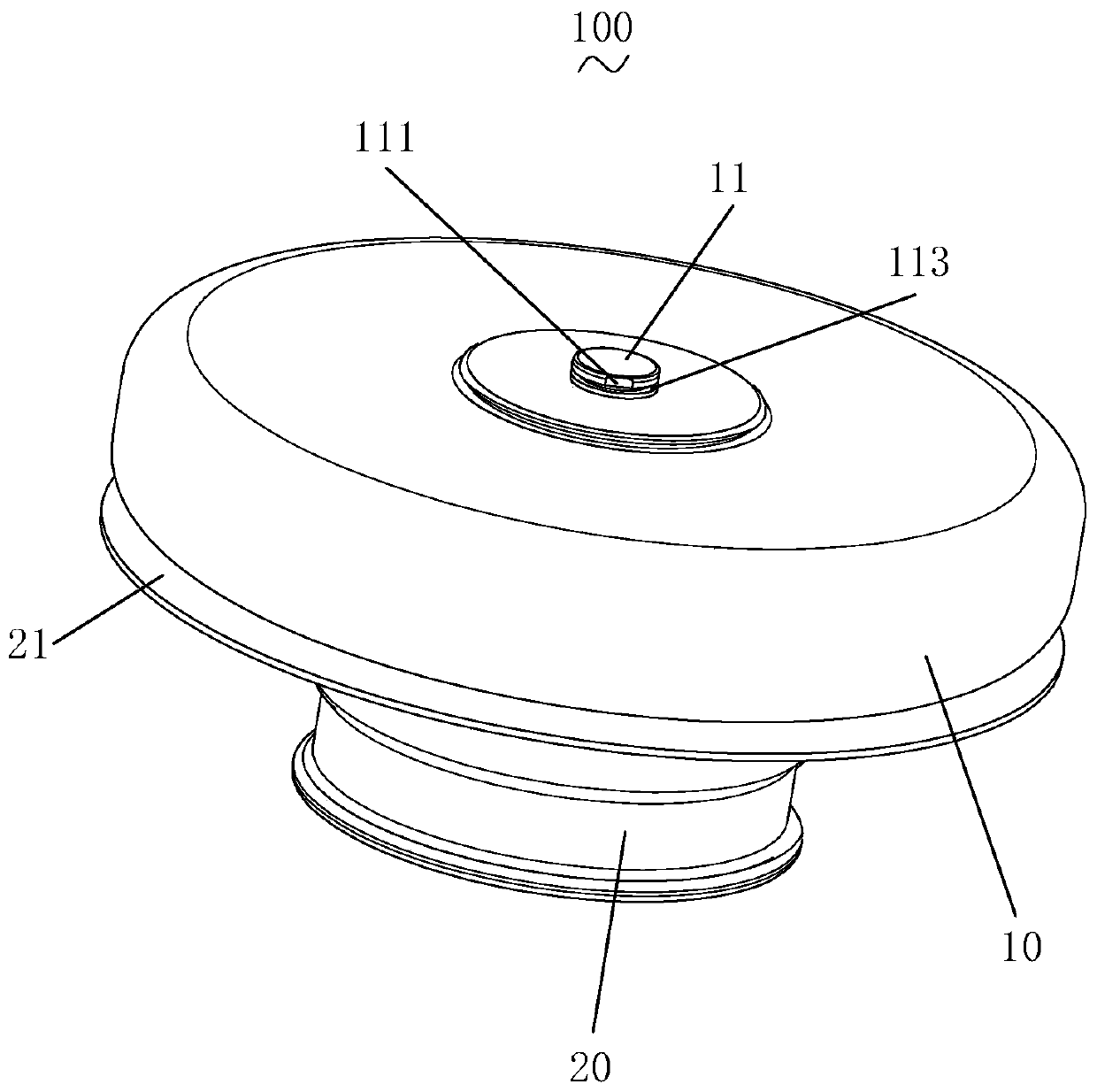

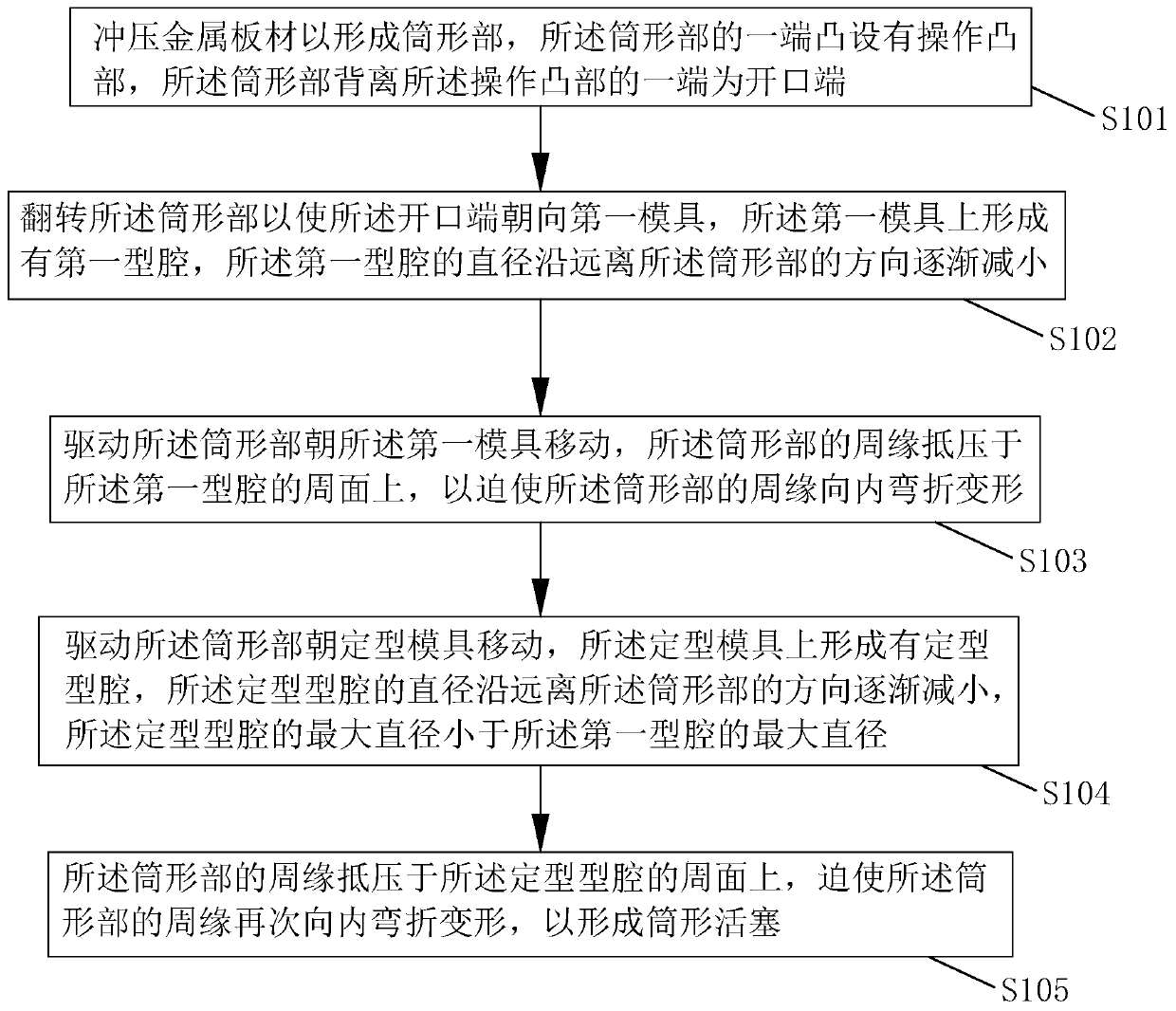

[0039] see Figure 1 to Figure 3 , a piston forming method of a rubber air spring, comprising the following steps:

[0040] In step S101, stamping the metal sheet to form a cylindrical portion 10, one end of the cylindrical portion 10 is protruded with an operating convex portion 11, and the end of the cylindrical portion 10 facing away from the operating convex portion 11 is an open end; For example, the operation convex portion 11 is formed by impact while forming the cylindrical portion 10 by impacting a sheet metal material.

[0041] In step S102, the cylindrical part 10 is turned over so that the open end faces a first mold (not shown in the figure), and a first cavity is formed on the first mold, and the diameter of the first cavity is along the The direction away from the cylindrical portion 10 gradually decreases;

[0042] In step S103, the cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com