Roll-on and roll-off boarding method for offshore wind power foundation steel pipe pile

A technology of offshore wind power and steel pipe piles, which is applied to ship accessories, transportation and packaging, and cargo handling equipment, etc. It can solve the problems of high risk factor, large loss of funds, and high operating cost, and achieve the effect of saving transportation funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

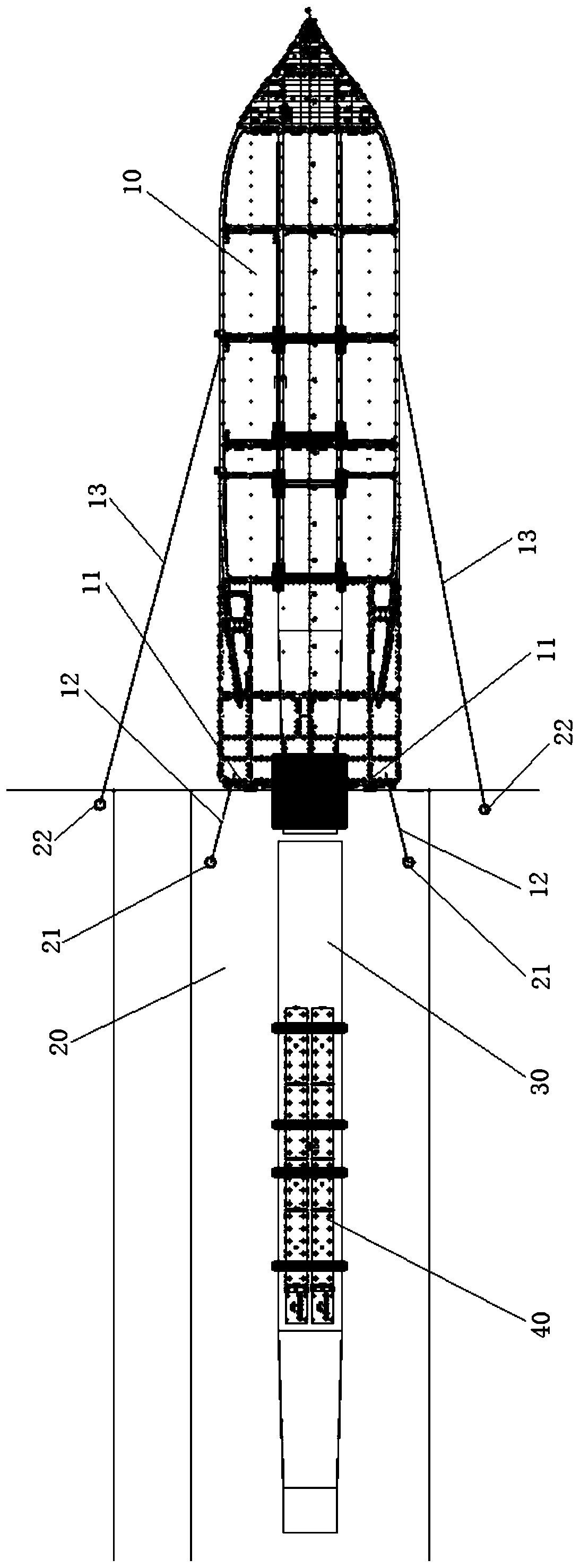

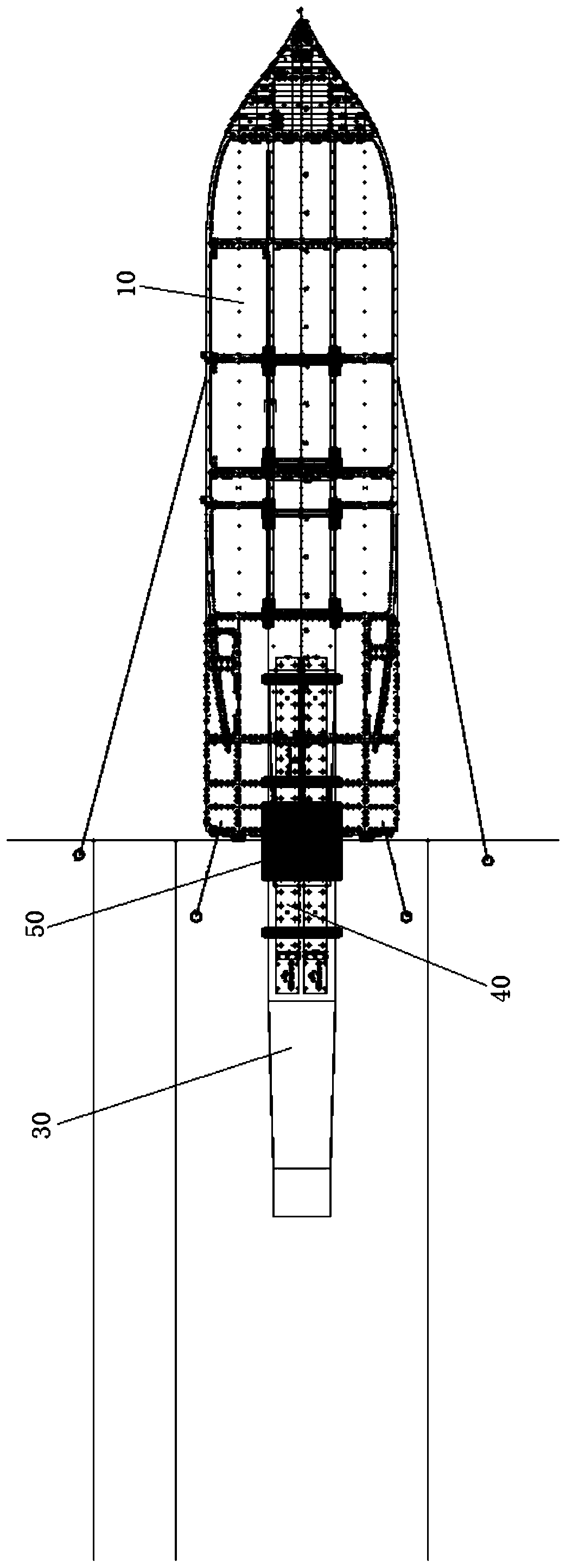

[0023] The present invention will be further described below in conjunction with accompanying drawing.

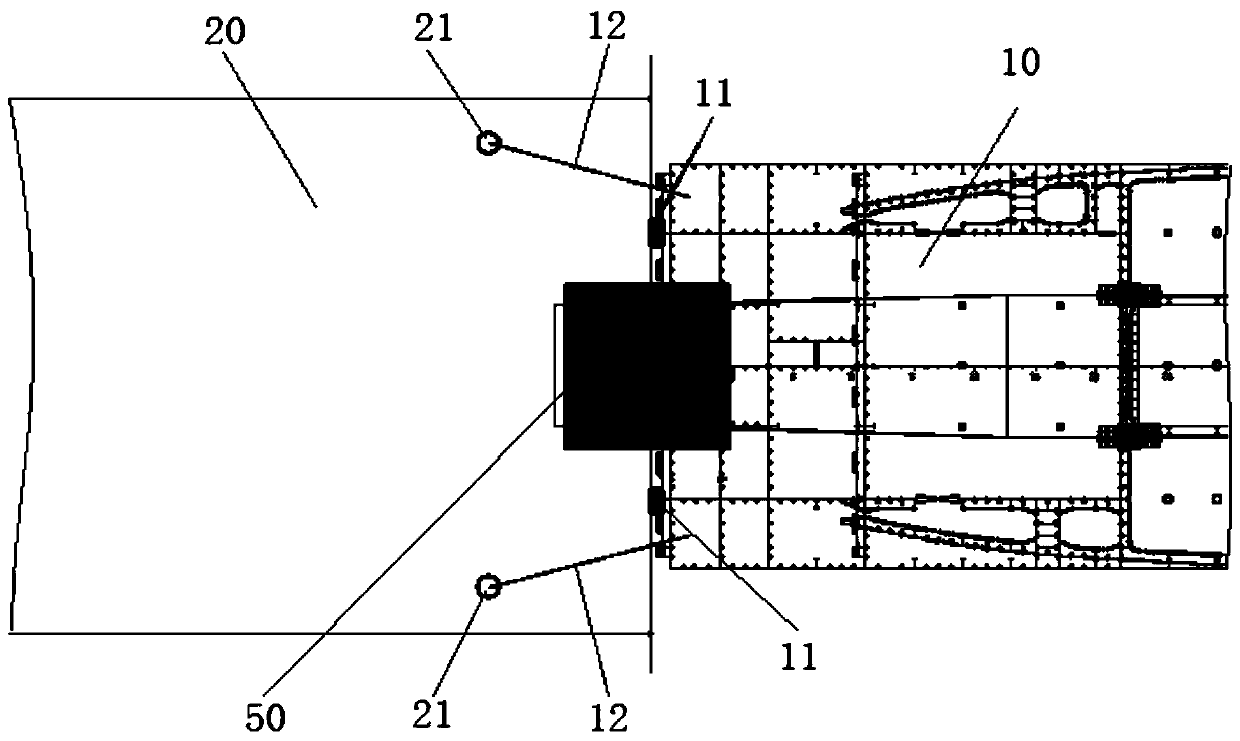

[0024] see Figure 1 to Figure 5 , the rolling-on-boarding method of steel pipe piles for offshore wind power foundations of the present invention is used to roll-roll steel pipe piles from a wharf to a piling barge and includes the following steps:

[0025] Step 1: Collect the hydrological data of the wharf during the loading period, measure the tide changes within 3 days and 72 hours before loading, and check and correct the collected hydrological data to calculate the tide rise and fall of the roll-off day. altitude and speed;

[0026] Step 2. According to the rate of rising and falling tides, calculate the pump flow rate of the ballast water of the piling barge, and calculate the boarding speed and operation time of the ro-ro vehicle; Type hydraulic flatbed truck; the boarding speed of the ro-ro assembly vehicle is less than 2km / h;

[0027] Step 3, first arrange the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com