Process for field shifting and transport of crawler crane without disassembling and assembling

A crawler crane and process technology, which is applied in the field of offshore petroleum engineering, can solve the problems of long construction period, consumption of manpower and vehicle crane resources, and high cost of the crawler crane transfer process, so as to save the transfer cost and shorten the transfer field. The effect of shortening the construction period and improving the efficiency of the transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Such as Figure 1-1 to Figure 13 Shown, the present invention adopts following steps:

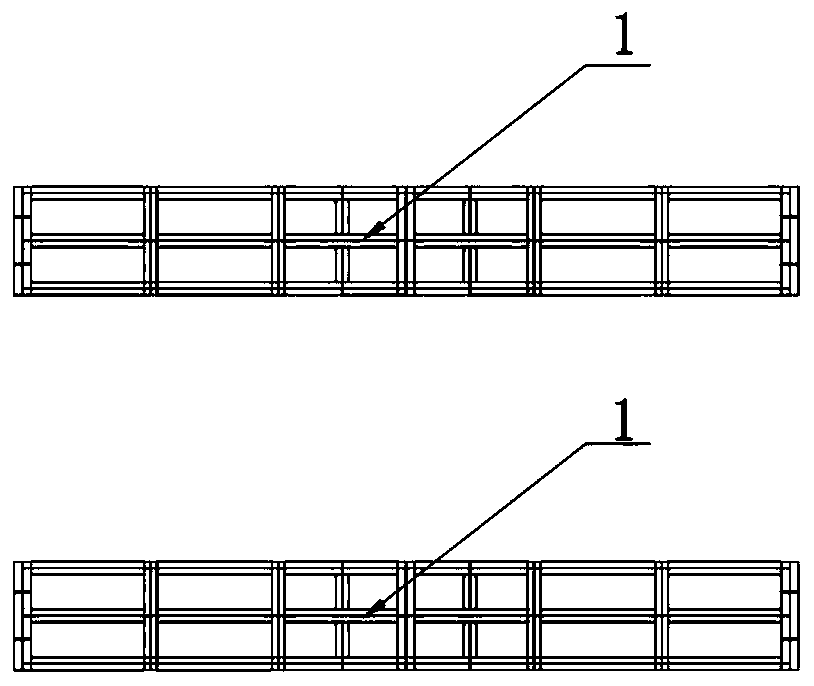

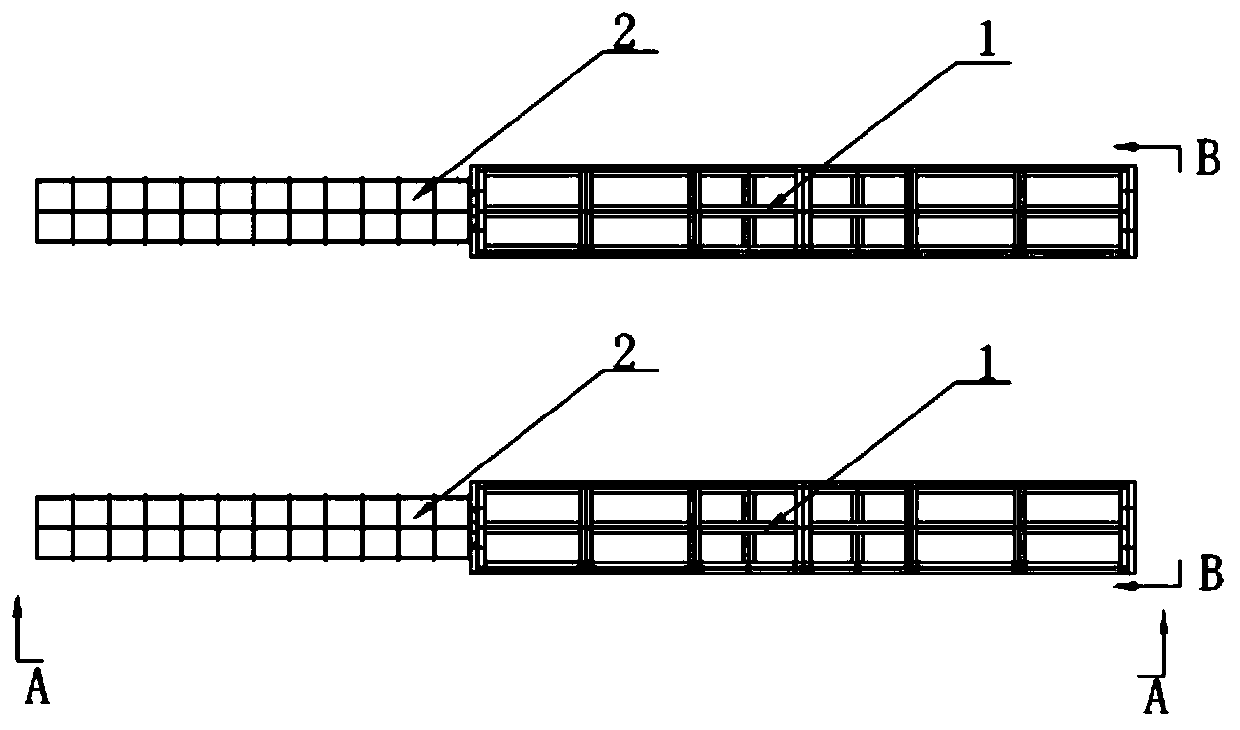

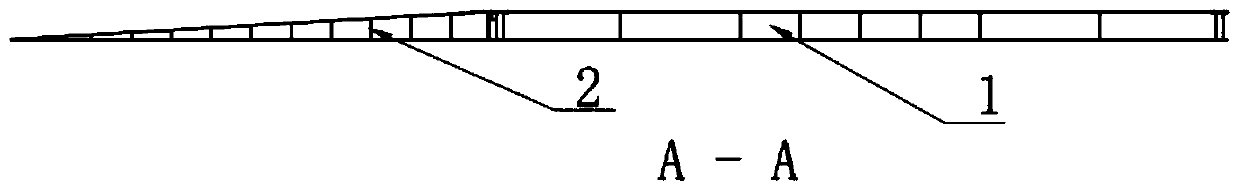

[0038] first step, such as Figure 1-1 to Figure 2-2 As shown, make dimension marks on the ground, and place the subgrade platform 1 and subgrade trestle 2 to the set positions;

[0039] The second step, such as image 3 , Figure 4 As shown, the crawler crane 3 is driven to the roadbed platform 1 through the roadbed trestle 2;

[0040] The size and arrangement of the above-mentioned roadbed platform 1 and roadbed trestle 2 are determined according to the size and type of the crawler crane 3 .

[0041] The third step, such as Figure 5 , Image 6 As shown, on the set position of the self-propelled modular transport vehicle 5, several load-sharing pads 4 are placed, and the load-sharing pads 4 are used for crawler cranes 3 with protrusions or depressions on the chassis. The self-propelled modular transport vehicle 5 is evenly stressed;

[0042] The fourth step, such as Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com