Reductant dosing unit with flow variation reduction and purge improvement

A feeding, dosing technology for RDU inserts that solves problems such as damaged injectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The following description of the exemplary embodiment(s) is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses. Unless otherwise specified, the terms "upstream" and "downstream" are intended to be relative to the flow of DEF through the RDU injector.

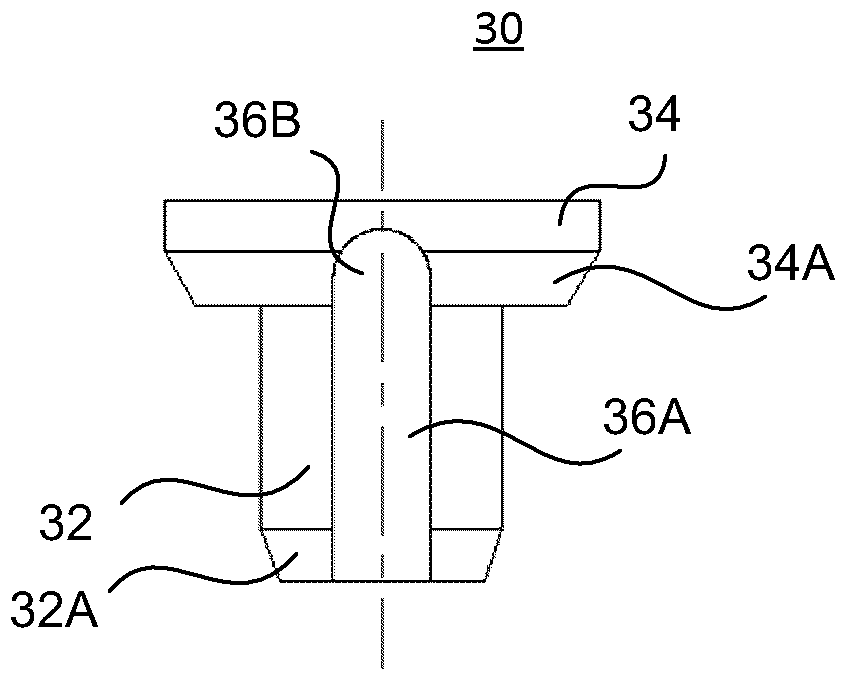

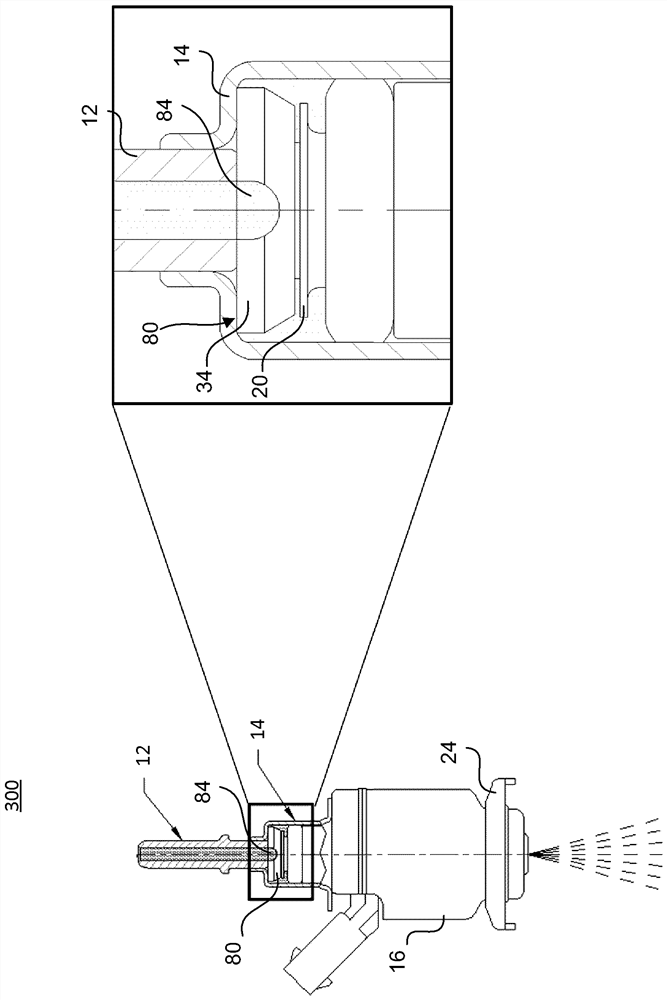

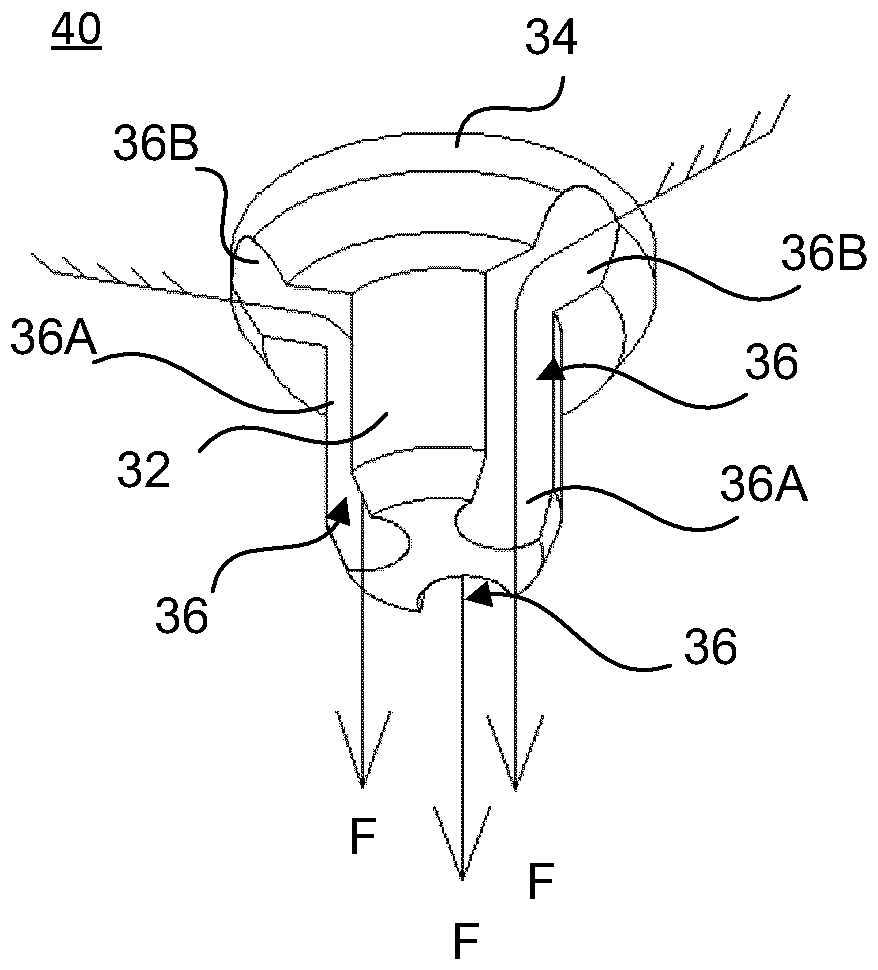

[0032] reference now Figure 3A and 3B , showing an RDU insert 30 according to an exemplary embodiment. The insert 30 fits within the cup 14 of the otherwise conventional RDU 10 and is sized and dimensioned to fit at least partially in the upstream end of the inlet pipe 20 of the conventional RDU injector 18 . A portion of the insert 30 extends from the inlet pipe 20 in the upstream direction. In this way, the insert 30 occupies a space within the cup portion 14 of the RDU 10 that would otherwise be occupied by DEF and / or one or more air bubbles. Since there is less space available for DEF and / or bubbles, less DEF needs to be purged and less air in the RDU 10 during a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com