MMC dynamic redundancy preventive maintenance method considering influence of operation conditions

A preventive maintenance, dynamic redundancy technology, applied in instrumentation, safety arrangements, control/regulation systems, etc., to solve problems such as not meeting the basic conditions of the constant failure rate model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

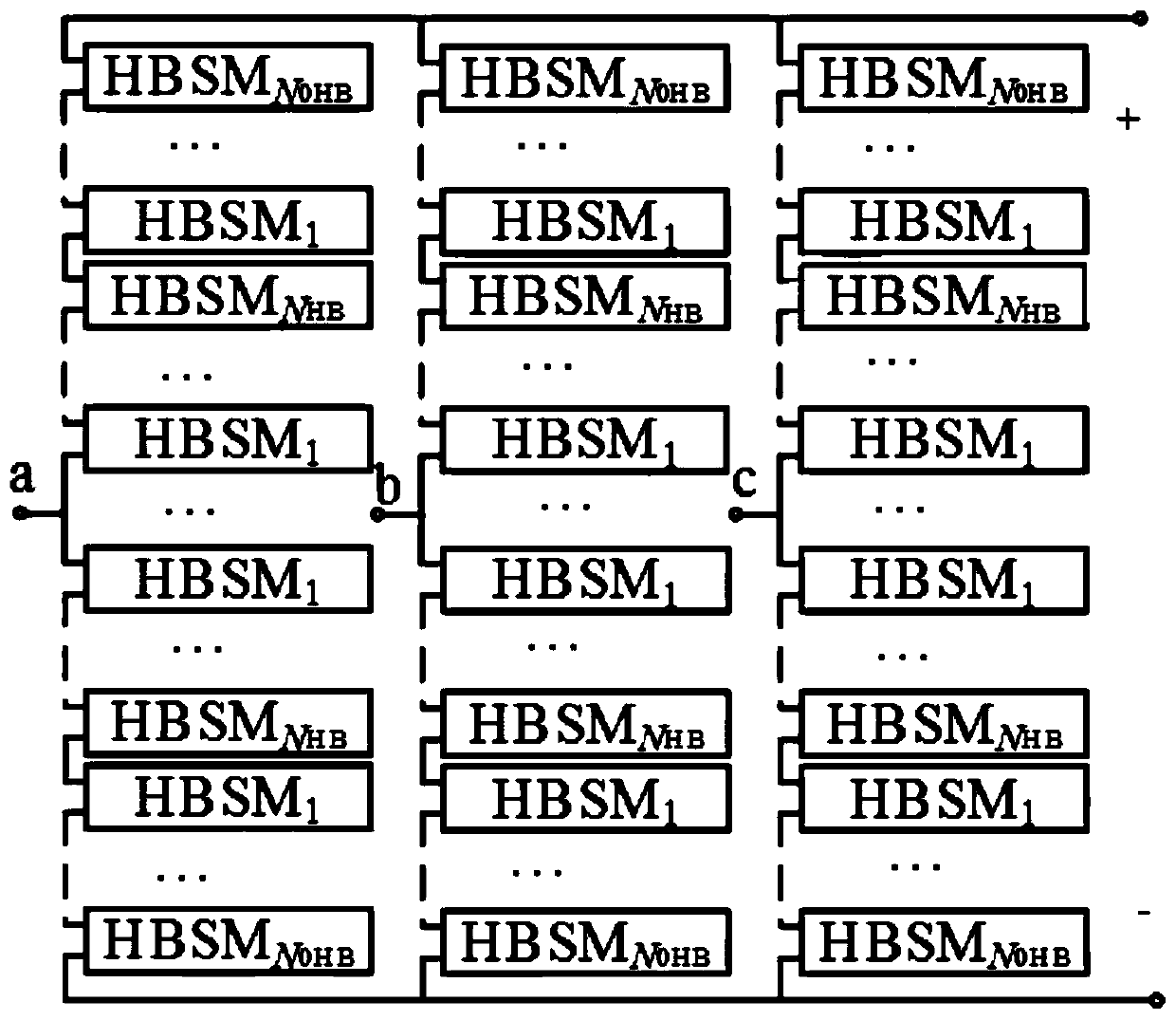

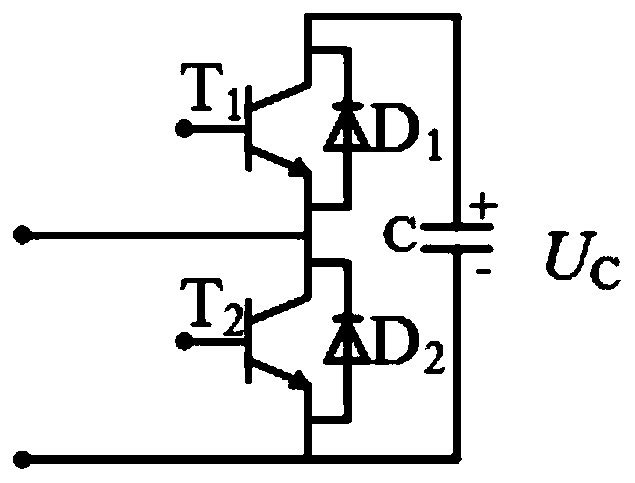

[0133] see Figure 1 to Figure 2 , the MMC dynamic redundancy preventive maintenance method considering the impact of operating conditions mainly includes the following steps:

[0134] 1) Determine the wind power transmission system to be maintained, and obtain the population sample data of MMC redundant sub-modules.

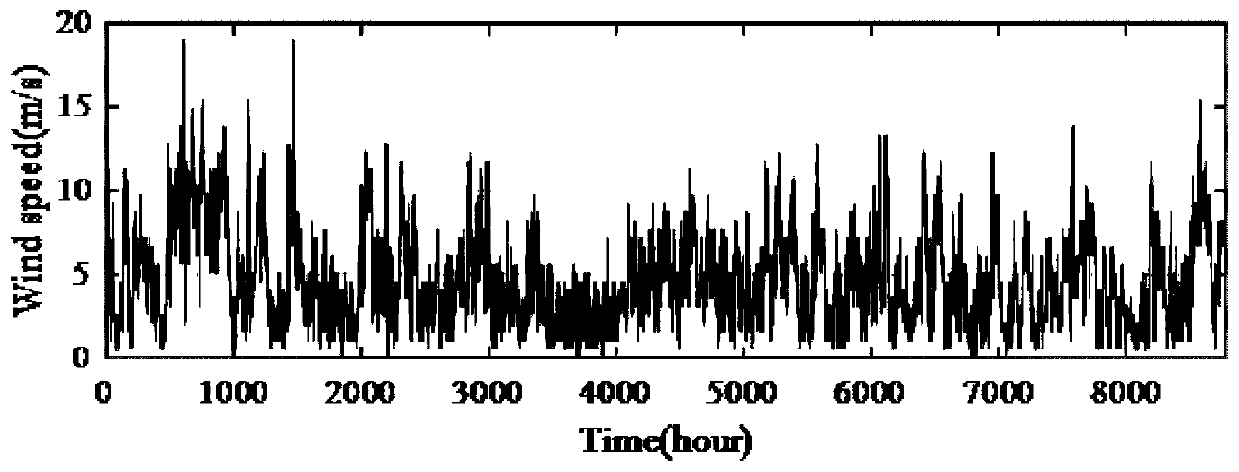

[0135] 2) Read the meteorological data of the wind power transmission system to generate a sample set of meteorological data for the entire life cycle.

[0136] The meteorological data of the wind power transmission system mainly include wind speed and air temperature of the wind power transmission system.

[0137] The method of generating the meteorological data sample set of the whole life cycle is to use the Monte Carlo method to randomly sample the data of the wind power transmission system.

[0138] 3) Establish the reliability evaluation model of MMC power devices in the wind power transmission system, and calculate the reliability of MMC power devices. ...

Embodiment 2

[0258] see Figure 3 to Figure 9 , an experiment to verify the MMC dynamic redundancy preventive maintenance method that takes into account the influence of operating conditions, mainly includes the following steps:

[0259] 1) Build a hybrid MMC power module.

[0260] In this embodiment, the FF1000R17IE4 power module of Infineon Company is used as the hybrid MMC power module, as shown in Table 1, and the wind speed and temperature data of Dublin, Ireland in 2016 and Qinghai in 2017 are used as the external working conditions of the wind farm and MMC, based on the present invention The proposed model is used to evaluate the maintenance cost of MMC. MMC and fan parameters are shown in Table 2.

[0261] Table 1 Thermal parameters of FF1000R17IE4 power module

[0262]

[0263]Table 2 Hybrid MMC and Fan Parameters

[0264] parameter value System rated capacity 124MW Grid side voltage 72kV DC side voltage 160kV HBSM benchmark number 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com