Automatic goods taking and placing method

An automatic, commodity technology, applied in the fields of instruments, data processing applications, logistics, etc., can solve the problems of troublesome storage or retrieval process, high error rate, discomfort, etc., to reduce time and error rate, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

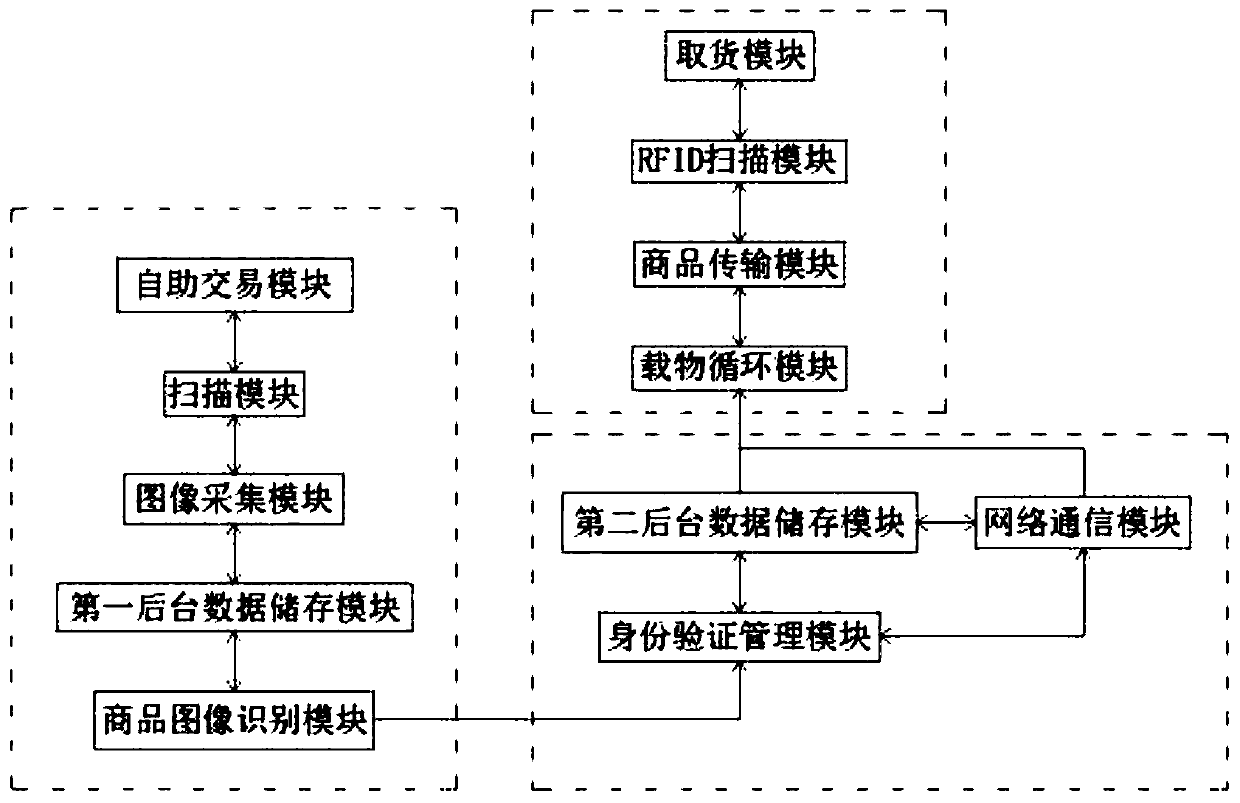

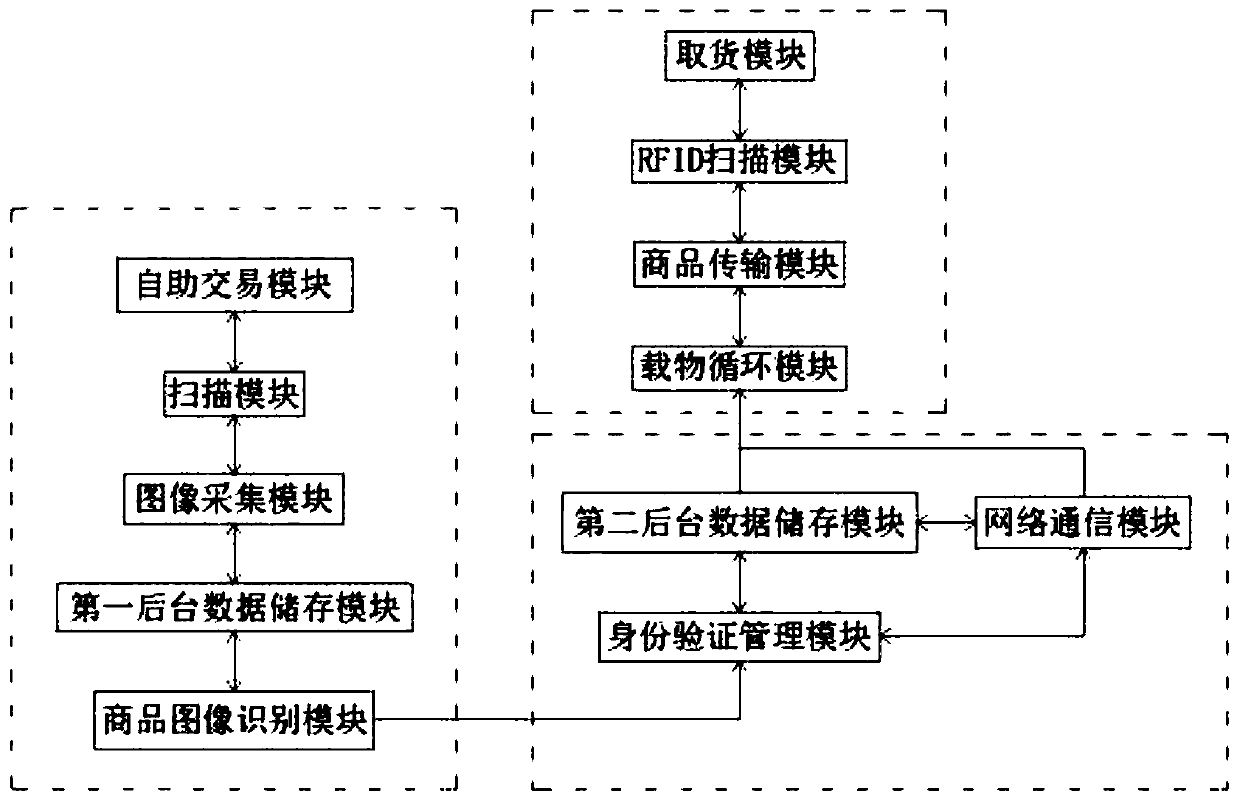

[0023] Such as figure 1 As shown, a method for automatically picking and placing goods is based on a main control system, a background management system and a picking system, and the main control system includes

[0024] Self-service transaction module, which is convenient for users to conduct self-service transactions without the participation of other personnel;

[0025] The scanning module is used to scan the identification label information of the commodity;

[0026] The image acquisition module collects real-time image information of commodities;

[0027] The first background data storage module stores the scanned commodity identification number information and commodity real-time image information, and classifies the commodities so that the commodity identification number information and commodity real-time image information can be used later;

[0028] The commodity image recognition module recognizes the real-time image information of the commodity, and starts the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com