Method for calibrating electronic tag with temperature sensor

A temperature sensor and electronic label technology, applied in the field of radio frequency identification, can solve the problems of expensive calibration of the thermostat, errors in electronic label temperature data, and high cost, and achieve the effects of lower stability accuracy requirements, lower calibration costs, and shorter temperature stabilization time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The implementation of the present invention is described below through specific examples and in conjunction with the accompanying drawings, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification. The present invention can also be implemented or applied through other different specific examples, and various modifications and changes can be made to the details in this specification based on different viewpoints and applications without departing from the spirit of the present invention.

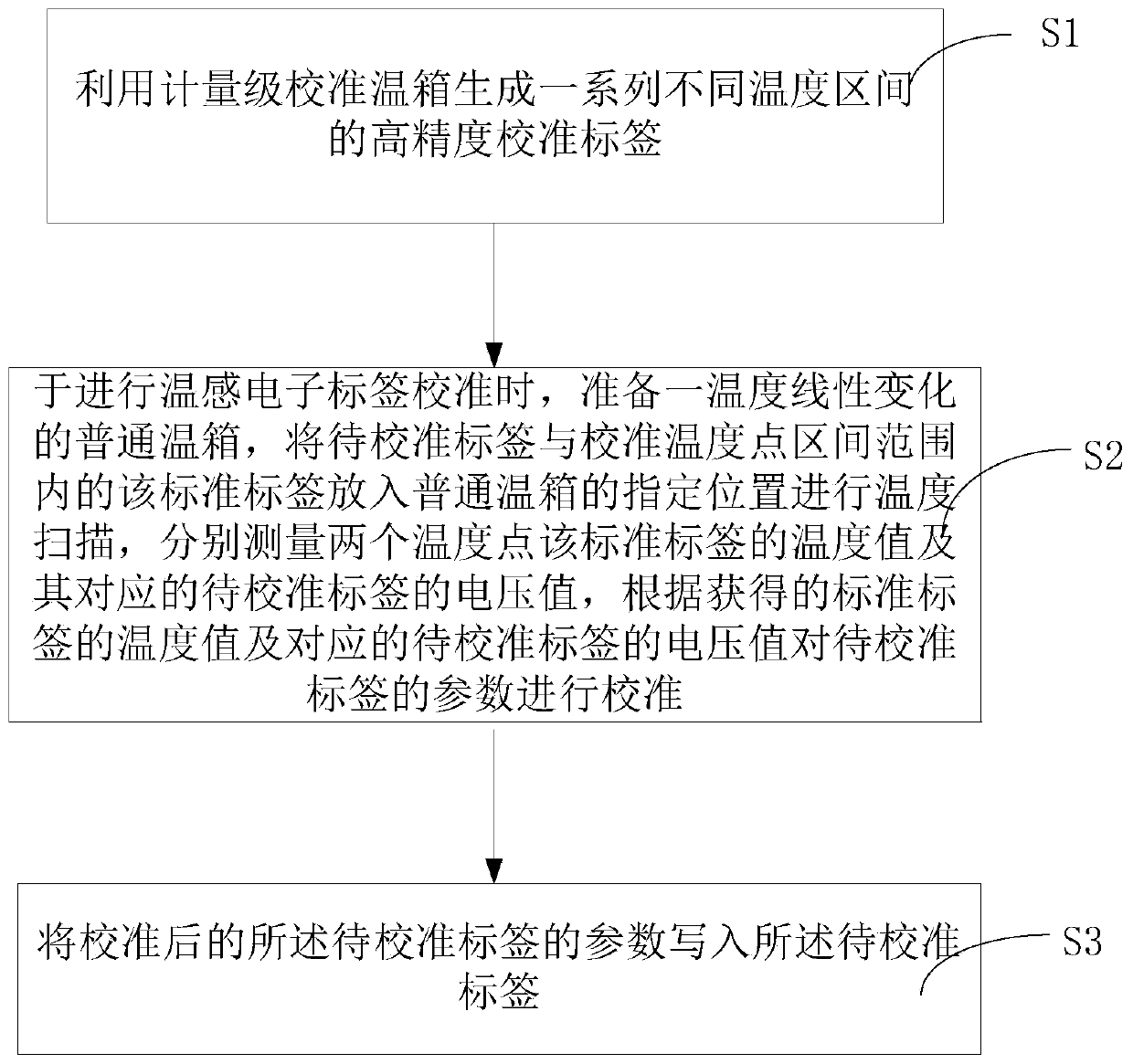

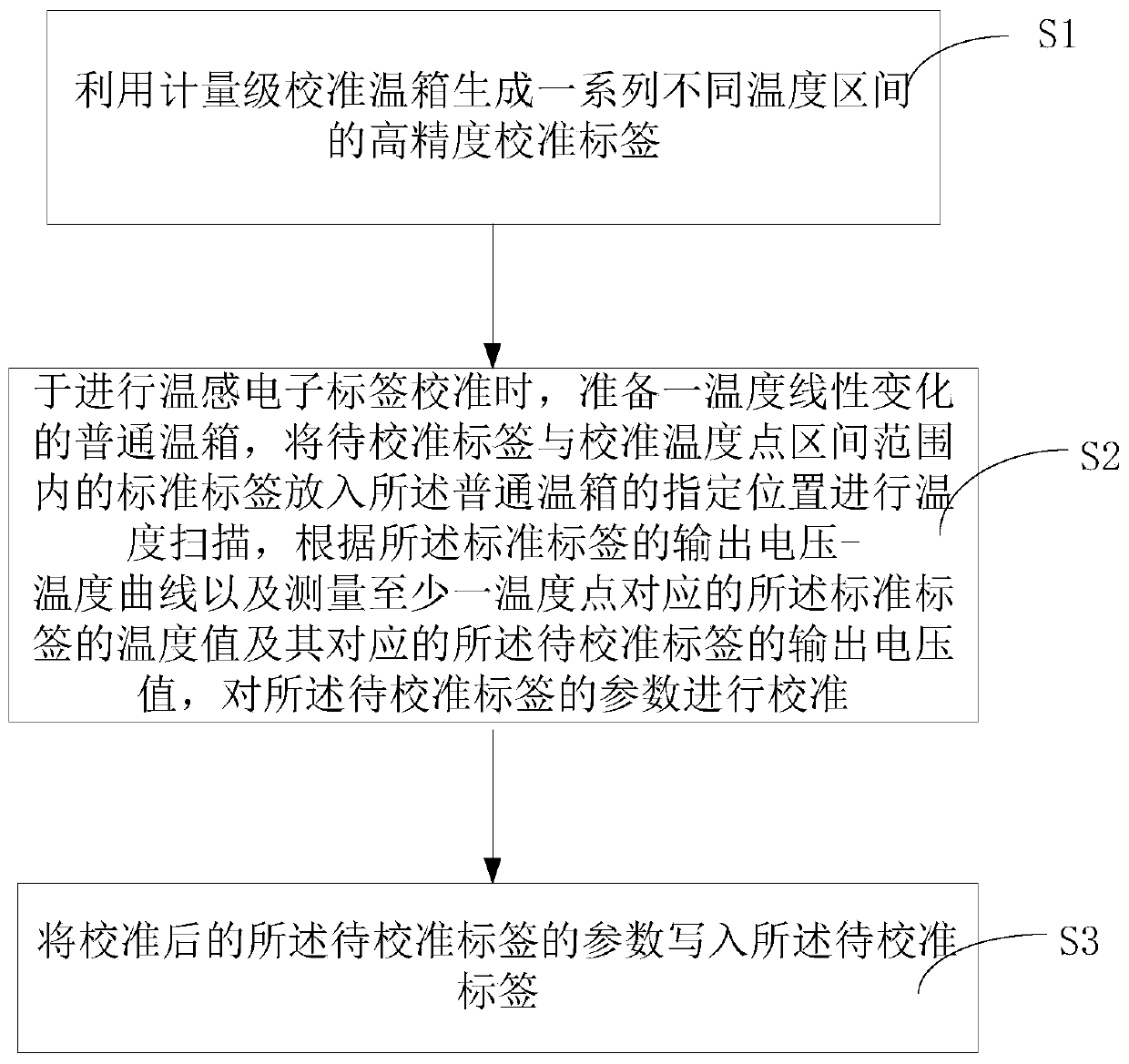

[0038] figure 1 It is a flow chart of steps of a method for calibrating an electronic tag with a temperature sensor in the present invention. like figure 1 As shown, a method for calibrating an electronic tag with a temperature sensor of the present invention comprises the following steps:

[0039] In step S1, a series of high-precision calibration labels with different temperature ranges...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com